Abstract

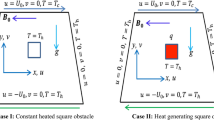

The multiphase flow of gas and fines in a packed bed proves to be an adequate representation that can reproduce various phenomena observed in complex packed bed reactors, such as iron-making blast furnaces, Direct Reduction of Iron shaft furnaces, and coal gasifier. However, most research neglect vital characteristics of these reactors, such as lateral inflow, presence of tuyere protrusion, and the raceway’s shape and size, leading to a significant incongruence with the reactor being modeled. The present work incorporates these features into a 2D numerical study of a gas–fines–solid system with validation through experimental studies. The mathematical modeling considers the gas and fines as an Eulerian–Eulerian system with the constant voidage model for the solid phase representing the packing particles. Well-established theoretical relations and correlations are used to determine the inter-phase forces and fines accumulation regions. Particular emphasis is placed on the accurate representation of the raceway formed at the tuyere exit, and three approaches are considered, viz., its absence, a correlation-based prediction, and an iso-stress-based model. The effect of various parameters such as gas inlet velocity, packing particle material, packing particle size, fines flux through the tuyere opening, and fines size is simulated and analyzed in detail with a marked interest in the raceway shape and size and accumulation profiles of the fines which are important parameters in the overall flow characterization. An insight into the physics based on the interaction forces between the phases, which is difficult to obtain experimentally, is offered to explain the change in the shape and size of the raceway and accumulation profile observed as the parameters mentioned above are varied. The results indicate an accurate mathematical model which demonstrates excellent predictive capabilities of the raceway and fines accumulation characteristics.

Graphical Abstract

Similar content being viewed by others

References

N. Hidaka, J. Iyama, T. Matsumoto, K. Kusakabe, and S. Morooka: Entrainment of fine particles with upward gas flow in a packed bed of coarse particles. Powder Technol., 1998, vol. 95(3), pp. 265–71.

M. Deguchi, K. Shibata, and J. Fukuoka: Combustion behaviour of pulverized coal using a coke-packed test furnace, CAMP-ISIJ, 1988.

Y. Matsui, T. Maki, R. Ono, T. Goto, R. Hori, and T. Kukihara: Combusibility at high rate fuel injection. Low coke rate operation at Kakogawa no. 2 blast furnace-3, CAMP-ISIJ, 1990.

K. Tamura, H. Ueno, K. Yamaguchi, M. Sugata, S. Amano, and K. Yamaguchi: Upper limits to combustibility of pulverized coal in blast furnace raceway and desirable injection position. Tetsu-to-Hagane., 1991, vol. 77(6), pp. 775–82.

J. Chen, T. Akiyama, H. Nogami, and J.-I. Yagi: Behavior of powders in a packed bed with lateral inlets. ISIJ Int., 1994, vol. 34(2), pp. 133–39.

T. Pham, D. Pinson, A. Yu, and P. Zulli: Gas–liquid–powder flow in moving particles: operational and non-operational regimes. Chem. Eng. Sci., 1999, vol. 54(21), pp. 5339–45.

H. Yamaoka: Flow characteristics of gas and fine particles in a twodimensional space of packed bed. Tetsu-to-Hagane., 1986, vol. 72(16), pp. 2194–2201.

K. Kusakabe, T. Yamaki, and S. Morooka: Direct measurement of ascending flow of fines through packed bed of coarse particles. Tetsu-to-Hagane., 1991, vol. 77(9), pp. 1413–18.

M. Ichida, T. Nakayama, K. Tamura, H. Shiota, K. Araki, and Y. Sugisaki: Behavior of fines in the blast furnace. ISIJ Int., 1992, vol. 32(4), pp. 505–13.

T. Nishi, H. Haraguchi, Y. Miura, S. Sakurai, K. Ono, and H. Kanoshima: Relationship between shape of raceway and productivity of blast furnace taking account of properties of coke sampled at Tuyere level. Trans. Iron Steel Inst. Jpn., 1982, vol. 22(4), pp. 287–96.

J. Wagstaff and W. Holman: Comparison of blast furnace penetration with model studies. JOM., 1957, vol. 9(3), pp. 370–76.

G. Sastry, G. Gupta, and A. Lahiri: Cold model study of raceway under mixed particle conditions. Ironmaking Steelmaking., 2003, vol. 30(1), pp. 61–65.

H. Nogami, H. Kawai, and J.I. Yagi: Measurement of three-dimensional raceway structure in small scale cold model by x-ray computed tomography. Tetsu-To-Hagane., 2014, vol. 100(2), pp. 256–61.

V. Mojamdar, G.S. Gupta, and A. Puthukkudi: Raceway formation in a moving bed. ISIJ Int., 2018, vol. 58(8), pp. 1396–401.

S. Yuu, T. Umekage, and T. Miyahara: Predicition of stable and unstable flows in blast furnace raceway using numerical simulation methods for gas and particles. ISIJ Int., 2005, vol. 45(10), pp. 1406–15.

S. Natsui, S. Ueda, Z. Fan, N. Andersson, J. Kano, R. Inoue, and T. Ariyama: Characteristics of solid flow and stress distribution including asymmetric phenomena in blast furnace analyzed by discrete element method. ISIJ Int., 2010, vol. 50(2), pp. 207–14.

J. Hilton and P. Cleary: Raceway formation in laterally gas-driven particle beds. Chem. Eng. Sci., 2012, vol. 80, pp. 306–16.

Z.-X. Di, Z.-G. Luo, Y.-Z. Han, Z.-S. Zou, and J.-X. Li: Fractal study on raceway boundary. J. Iron. Steel Res. Int., 2011, vol. 18(5), pp. 16–19.

S. Rajneesh and S. Sarkar: Prediction of raceway size in blast furnace from two dimensional experimental correlations. ISIJ Int., 2004, vol. 44(8), pp. 1298–1307.

P. Flint and J. Burgess: A fundamental study of raceway size in two dimensions. Metall. Mater. Trans. B., 1992, vol. 23B(3), pp. 267–83.

J. Elliott, R. Buchanan, and J. Wagstaff: Physical conditions in the combustion and smelting zones of a blast furnace. JOM., 1952, vol. 4(7), pp. 709–17.

J.-J. Sun, Z.-G. Luo, Z.-X. Di, T. Zhang, H. Zhou, and Z.-S. Zou: Definition of raceway boundary using fractal theory. J. Iron. Steel Res. Int., 2015, vol. 22(1), pp. 36–41.

Z. Sun, X. Tang, and G. Cheng: Numerical simulation for tortuosity of porous media. Micropor. Mesopor. Mater., 2013, vol. 173, pp. 37–42.

Y. Lu, Z. Jiang, X. Zhang, S. Liu, J. Wang, and X. Zhang: Determination of void boundary in a packed bed by laser attenuation measurement. Particuology., 2020, vol. 51, pp. 72–79.

S. Rajneesh and G. Gupta: Importance of frictional forces on the formation of cavity in a packed bed under cross flow of gas. Powder Technol., 2003, vol. 134(1–2), pp. 72–85.

J. Guo, S. Cheng, H. Zhao, H. Pan, P. Du, and Z. Teng: A mechanism model for raceway formation and variation in a blast furnace. Metall. Mater. Trans. B., 2013, vol. 44B(3), pp. 487–94.

W. Li, J. Zhang, S. Karnati, Y. Zhang, F. Liou, J. Newkirk, K. Taminger, and W. Seufzer: Modeling and experimental investigation of pre-mixed multipowder flow in fabricating functional gradient material by laser metal deposition process, in: 2016 International Solid Freeform Fabrication Symposium, University of Texas at Austin, 2016.

V. Rudolph: Comparison of blast furnace raceway size with theory. ISIJ Int., 2006, vol. 46(2), pp. 195–201.

H. Aoki, H. Nogami, H. Tsuge, T. Miura, and T. Furukawa: Simulation of transport phenomena around the raceway zone in the blast furnace with and without pulverized coal injection. ISIJ Int., 1993, vol. 33(6), pp. 646–54.

Y. Sun, R. Chen, Z. Zhang, G. Wu, H. Zhang, L. Li, Y. Liu, X. Li, and Y. Huang: Numerical simulation of the raceway zone in melter gasifier of corex process. Processes., 2019, vol. 7(12), p. 867.

Y. Zhuo and Y. Shen: Three-dimensional transient modelling of coal and coke co-combustion in the dynamic raceway of ironmaking blast furnaces. Appl Energy., 2020, vol. 261, p. 114456.

X. Peng, J. Wang, H. Zuo, and Q. Xue: Evolution and physical characteristics of a raceway based on a transient Eulerian multiphase flow model. Processes., 2020, vol. 8(10), p. 1315.

X. Xu, L. Wu, et al.: Performance optimization criterion of blast furnace stave. Int. J. Heat Mass Transf., 2017, vol. 105, pp. 102–108.

V. Singh, G. Gupta, and S. Sarkar: Study of gas cavity size hysteresis in a packed bed using dem. Chem. Eng. Sci., 2007, vol. 62(22), pp. 6102–11.

Z. Miao, Z. Zhou, A. Yu, and Y. Shen: CFD-DEM simulation of raceway formation in an ironmaking blast furnace. Powder Technol., 2017, vol. 314, pp. 542–49.

Q. Hou, E. Dianyu, S. Kuang, Z. Li, and A. Yu: Dem-based virtual experimental blast furnace: a quasi-steady state model. Powder Technol., 2017, vol. 314, pp. 557–66.

E.R. Santana, G. Pozzetti, and B. Peters: Application of a dual-grid multiscale cfd-dem coupling method to model the raceway dynamics in packed bed reactors. Chem. Eng. Sci., 2019, vol. 205, pp. 46–57.

G. Wei, H. Zhang, X. An, B. Xiong, and S. Jiang: Cfd-dem study on heat transfer characteristics and microstructure of the blast furnace raceway with ellipsoidal particles. Powder Technol., 2019, vol. 346, pp. 350–62.

G. Wei, H. Zhang, X. An, and S. Jiang: Influence of particle shape on microstructure and heat transfer characteristics in blast furnace raceway with cfd-dem approach. Powder Technol., 2020, vol. 361, pp. 283–96.

J. Cui, Q. Hou, and Y. Shen: Cfd-dem study of coke combustion in the raceway cavity of an ironmaking blast furnace. Powder Technol., 2020, vol. 362, pp. 539–49.

S. Taya, S. Natsui, J.A. de Castro, and H. Nogami: Numerical analysis of raceway formation in isothermal and non-reactive packed bed. ISIJ Int., 2020, vol. 60(12), pp. 2669–77.

S. Sarkar, G. Gupta, J. Litster, V. Rudolph, E. White, and S. Choudhary: A cold model study of raceway hysteresis. Metall. Mater. Trans. B., 2003, vol. 34B(2), pp. 183–91.

S. Sarkar, G.S. Gupta, and S.-Y. Kitamura: Prediction of raceway shape and size. ISIJ Int., 2007, vol. 47(12), pp. 1738–44.

C. Orr: Particulate Technology, Macmillan, New York, 1966.

S. Zhang and A. Yu: Computational investigation of slugging behaviour in gasfluidised beds. Powder Technol., 2002, vol. 123(2–3), pp. 147–65.

J. Grace: Fluidized bed hydrodynamics. Int. J. Multiphase Flow., 1982, vol. 8, pp. 304–06.

S. Ergun: Fluid flow through packed columns. Chem. Eng. Prog., 1952, vol. 48, pp. 89–94.

J. Richardson and W. Zaki: The sedimentation of a suspension of uniform spheres under conditions of viscous flow. Chem. Eng. Sci., 1954, vol. 3(2), pp. 65–73.

K. Shibata, M. Shimizu, S.-I. Inaba, R. Takahashi, and J.-I. Yagi: Pressure loss and hold-up powders for gas-powder two phase flow in packed beds. ISIJ Int., 1991, vol. 31(5), pp. 434–39.

X. Dong, S. Zhang, D. Pinson, A. Yu, and P. Zulli: Gas–powder flow and powder accumulation in a packed bed: Ii: numerical study. Powder Technol., 2004, vol. 149(1), pp. 10–22.

S. Lakshminarasimha, A. Maurya, G. Gupta, and G. V. A. Chaitanya: Quantification of powder holdups in the presence of a cavity with lateral gas-powder injection in a packed bed, Can. J. Chem. Eng. (2022, Accepted).

A.-B. Yu and N. Standish: Estimation of the porosity of particle mixtures by a linear-mixture packing model. Ind. Eng. Chem. Res., 1991, vol. 30(6), pp. 1372–85.

S. Kamble, S. Lakshminarasimha, A. Maurya, and G. Gupta: Validation of pressure drop in gas–fine flow in a packed bed with various types of injection system (lateral and bottom). Trans. Indian Inst. Met., 2020, vol. 73, pp. 2081–87.

S. Sarkar and G. Gupta: Development of a two-dimensional mathematical model for stress and velocity distribution in a packed bed. Metall. Mater. Trans. B., 2007, vol. 38B(6), pp. 965–75.

S.V. Patankar: Numerical Heat Transfer and Fluid Flow, CRC Press, Boca Raton, 2018.

J. Kim and P. Moin: Application of a fractional-step method to incompressible Navier-stokes equations. J. Comput. Phys., 1985, vol. 59(2), pp. 308–23.

V. Ranade: Computational Flow Modelling for Chemical Reactor Engineering, Academic Press Inc., New York, 2002.

S. Lakshminarasimha: Experimental study of multiphase flow in the presence of raceway in the packed beds, Ph.D. thesis, Indian Institute of Science (2021).

G.S. Gupta, S. Lakshminarasimha, and M. Shrenik: Quantitative measurement of powder holdups in the packed beds. Trans. Indian Inst. Met., 2021, vol. 75, pp. 381–95.

Y. Omori: Blast furnace phenomena and modelling, Committee on reaction within blast furnace, 1987.

Acknowledgments

We wish to thank Prof. MR Lollchund for the initial assistance in developing the theoretical analysis. We also wish to greatly acknowledge the financial support provided by the Department of Science and Technology (DST), New Delhi, India (Grant Nos. SB/53/ME/027/2014 and CRG/2019/000292).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 15, 2011; accepted March 23, 2022.

Rights and permissions

About this article

Cite this article

Kamble, S., Bosco, F.S.D. & Gupta, G.S. Effect of Raceway Shape and Size on Gas and Fines Flow Behavior in a Packed Bed. Metall Mater Trans B 53, 2117–2131 (2022). https://doi.org/10.1007/s11663-022-02512-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02512-7