Abstract

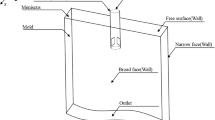

For the application of a novel in-mold multi-poles electromagnetic rotative stirring (EMRS) instrumentation, a coupled three-dimensional numerical model is established to study the effect of EMRS on the metallurgical behavior in the mold of 2150 mm × 230 mm size slab casting. The model is validated experimentally through the measurement of magnetic flux density and electromagnetic force. It has been proved that both the magnetic flux density and electromagnetic force produced by the in-mold multi-poles traveling wave stirring are mainly concentrated in front of the initial solidified shell along the mold wide sides especially at an optimal frequency of 4 Hz, which can produce a beneficial horizontal flow pattern for interstitial-free steels to wash away any hooked inclusions and/or bubbles under the meniscus. When the current intensity increases from 0 to 400 A, six swirl flows are observed in the cross-section of the mold stirrer center, the jet flow impinging depth decreased by 162 mm, and the tangential velocities of fluid flow on the solidification front increased by 0.126 and 0.120 m s−1 on the narrow and wide sides, respectively, which should be the key reasons for the washing and floating removal of the locally hooked inclusions. Meanwhile, the level fluctuation and shell thickness on the narrow side of mold decreased at first but increased later with an increasing current. A comprehensive evaluation method for the mold metallurgical behavior of EMRS is proposed based on the results from the numerical model and the statistical analysis of defect ratio in actual steel productions. It suggests that the optimum stirring current intensity is 300 A, which can cut the defect ratio of the hot rolled plates down to the lowest value of 0.06 pct while produced by the slab continuous casting process.

Similar content being viewed by others

References

B.G. Thomas and L.F. Zhang: ISIJ Int., 2007, vol. 41, pp. 1181–2119.

J. Sengupta, H.J. Shini, B.G. Thomas, and S.H. Kim: Acta Mater., 2006, vol. 54, pp. 1165–73.

P.C. Xiao, X.Y. Wu, L.G. Zhu, and Z.X. Liu: Metall. Res. Technol., 2019, vol. 116, pp. 103–13.

Z.H. Chen, E.G. Wang, and J.C. He: Steelmaking., 2004, vol. 20, pp. 48–52.

K. Takatani: Tetsu-to-Hagane., 2004, vol. 90, pp. 751–57.

J. Nagai, K. Suzuki, S. Kojima, and S. Kollberg: Iron Steel Eng., 1984, vol. 61, pp. 41–47.

H. Harada, E. Takeuchi, M. Zeze, and H. Tanaka: Appl. Math. Model., 1998, vol. 22, pp. 873–82.

M. Zeze, H. Harada, E. Takeuchi, and T. Ishi: Iron Steelmak., 1993, vol. 20, pp. 53–57.

S.M. Cho and B.G. Thomas: Metals., 2019, vol. 9, p. 471.

A. Lehman: Fuel Energy Abstr., 1996, vol. 4, p. 293.

S. Itoyama: CAMP-ISIJ, 2001, vol. 14, p. 893.

H.H. Visser, W.D. Knoop, W.F.M. Damen, T.G. Essem, and J.P.T.M. Brockhoff: Metall. Ital., 2009, vol. 101, pp. 489–99.

S. Kunstreich: Metall. Res. Technol., 2003, vol. 100, pp. 395–408.

S. Kunstreich: Metall. Res. Technol., 2003, vol. 100, pp. 1043–61.

Y.B. Yin, J.M. Zhang, B. Wang, and Q.P. Dong: Ironmak. Steelmak., 2019, vol. 46, pp. 682–91.

B. Li, H.B. Lu, Y.B. Zhong, Z.M. Ren, and Z.S. Lei: ISIJ Int., 2020, vol. 60, pp. 1204–12.

D.B. Jiang and M.Y. Zhu: Steel Res. Int., 2015, vol. 86, pp. 993–1003.

P. Wang, Z. Zhang, Z.P. Tie, M. Qi, P. Lan, S.X. Li, Z.B. Yang, and J.Q. Zhang: Metals., 2019, vol. 9, pp. 1083–97.

M.R. Aboutalebi, R.I.L. Guthrie, and S.H. Seyedein: Appl. Math. Model., 2007, vol. 31, pp. 1671–89.

W.P. Jones and B.E. Launder: Int. J. Heat Mass Transf., 1973, vol. 16, pp. 1119–30.

K.Y.M. Lai, M. Salcudean, S. Tanaka, and R.I.L. Guthrie: Metall. Mater. Trans. B., 1986, vol. 17B, pp. 449–59.

Q.P. Dong, J.M. Zhang, Y.B. Yin, and B. Wang: Metals., 2017, vol. 7, p. 209.

Q.Q. Wang and L.F. Zhang: JOM., 2016, vol. 68, pp. 2170–79.

S.X. Li, X.M. Zhang, L. Li, P. Lan, H.Y. Tang, and J.Q. Zhang: Chin. J. Eng., 2019, vol. 41, pp. 199–208.

P. Wang, S.X. Li, Z.P. Tie, H.S. Liu, H.Y. Tang, P. Lan, and J.Q. Zhang: AIST, 2019, pp. 1363–71.

P. Wang, S.X. Li, Z. Zhang, Z.P. Tie, Y.N. Dong, W. Zhang, and J.Q. Zhang: J. Mech. Eng., 2020, vol. 56, pp. 99–106.

P.P. Sahoo, A. Kumar, J. Halder, and M. Raj: ISIJ Int., 2009, vol. 49, pp. 521–28.

L.F. Zhang: Iron Steel Technol., 2010, vol. 7, pp. 55–69.

Y.Q. Li, J.H. Liu, Y. He, K. Dong, P. Zhang, and G.Y. Zheng: Spec. Steel., 2019, vol. 40, pp. 1–6.

S. Kittaka, T. Kanki, K. Watanabe, and Y. Miura: Nippon Steel Tech. Rep., 2002, vol. 86, pp. 68–73.

B. Mao, G.F. Zhang, and A.W. Li: Theory and Technology of Electromagnetic Stirring for Continuous Cast Steel, Metallurgical Industry Press, Beijing, 2012, p. 225.

B.H. Thomas: Iron Steel Technol., 2006, vol. 3, p. 127.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (NSFC) (Grant Nos. 51874033 and U1860111).

Author Contributions

PW and HX: conceptualization; PW and XC: methodology; WL and BY: investigation; HT and JZ: resources; PW, HX, and XC: writing—original draft preparation; PW, HT, and JZ: writing—review and editing; XC and PW: visualization; HX, HT, and JZ: supervision; HT and JZ: project administration.

Conflict of interest

The authors declare no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, P., Xiao, H., Chen, Xq. et al. Improved In-Mold Metallurgical Behavior for Slab Casting of IF Steels by a Novel Multi-poles Electromagnetic Stirring. Metall Mater Trans B 53, 1691–1702 (2022). https://doi.org/10.1007/s11663-022-02478-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02478-6