Abstract

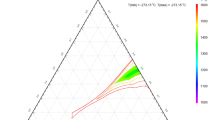

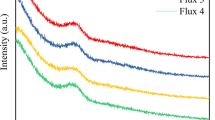

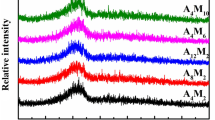

The effect of MgO on the viscosity and structure of CaO-Al2O3-B2O3-based non-reactive mold flux was studied by rotational viscometer, molecular dynamics (MD) simulations, and Raman spectroscopy. The results show that with the increase of MgO content from 3 °C to 9 pct, the viscosity (the testing temperature is 1300 °C) of the sample decreases from 0.39 to 0.26 Pa seconds, the activation energy decreases from 158.7 to 119.7 kJ/mol, and the break temperature (Tbr) decreases from 1212 °C to 1157 °C. Triple-coordinated oxygen and highly coordinated Al appear in the mold flux to compensate for the excess negative charge of [AlO4]5- tetrahedron. With the increase of MgO content, the stability of the Al-O network structure is enhanced, but the degree of polymerization of melt and the complexity of network structure decrease. With the increase of MgO content, the amount of bridging oxygen in the system decreases, and the polymerization degree of the aluminate network in mold flux decreases. The results of Raman spectra are consistent with those of MD simulation. Therefore, MgO can simplify the melt structure and reduce the viscosity of mold flux.

Similar content being viewed by others

References

Q. Wang, S.T. Qiu, and P. Zhao: Metall. Mater. Trans. B., 2012, vol. 43B, pp. 424–30. https://doi.org/10.1007/s11663-011-9600-8.

W.L. Wang, K. Blazek, and A. Cramb: Metall. Mater. Trans. B., 2008, vol. 39B, pp. 66–74. https://doi.org/10.1007/s11663-007-9110-x.

T. Wu, Q. Wang, S.P. He, L.F. Xu, X. Long, and Y.J. Lu: Steel Res. Int., 2012, vol. 83, pp. 1194–1202. https://doi.org/10.1002/srin.201200092.

Q. Wang, M. Sun, S.T. Qiu, Z. Tian, G. Zhu, L. Wang, and P. Zhao: Metall. Mater. Trans. B., 2014, vol. 45B, pp. 540–46. https://doi.org/10.1007/s11663-013-9929-2.

Q. Liu, G. Wen, J. Li, X. Fu, P. Tang, and W. Li: Ironmaking Steelmaking., 2000, vol. 41, pp. 292–97. https://doi.org/10.1179/1743281213Y.0000000131.

S. Ren, J. Zhang, L. Wu, W. Liu, Y. Bai, X. Xing, B. Su, and D. Kong: ISIJ Int., 2012, vol. 52, pp. 984–91. https://doi.org/10.2355/isijinternational.52.984.

X.H. Huang, J.L. Liao, K. Zheng, H.H. Hu, F.M. Wang, and Z.T. Zhang: Ironmaking Steelmaking., 2014, vol. 41, pp. 67–74. https://doi.org/10.1179/1743281213Y.0000000107.

S.Y. Choi, D.H. Lee, D.W. Shin, J.W. Cho, and J.M. Park: J. Non-Cryst. Solids., 2004, vol. 345, pp. 157–60. https://doi.org/10.1016/j.jnoncrysol.2004.08.015.

Y. Gao, S. Wang, C. Hong, X. Ma, and F. Yang: Int. J. Miner. Metall. Mater., 2014, vol. 21, pp. 353–62. https://doi.org/10.1007/s12613-014-0916-7.

E. Gao, W. Wang, and L. Zhang: J. Non-Cryst. Solids., 2017, vol. 435, pp. 79–86. https://doi.org/10.1016/j.jnoncrysol.2017.07.029.

H. Wang, P. Tang, G.H. Wen, and X. Yu: Chin. J. Process. Eng., 2010, vol. 10, pp. 905–10. https://doi.org/10.1155/2010/293410.

J. Qi, C. Liu, H. Liu, C. Li, and M. Jiang: J. Non-Cryst. Solids., 2021, vol. 559, pp. 1–8. https://doi.org/10.1016/j.jnoncrysol.2021.120681.

Z.R. Li, X.C. You, M. Li, Q. Wang, S.P. He, and Q.Q. Wang: Met. Open Access Metal. J., 2019, vol. 9, pp. 1–13. https://doi.org/10.3390/met9020142.

W. Yan, W. Chen, Y. Yang, C. Lippold, and A. McLean: Ironmaking Steelmaking., 2015, vol. 42, pp. 698–704. https://doi.org/10.1179/1743281215Y.0000000024.

B.X. Lu, K. Chen, W.L. Wang, and B. Jiang: Metall. Mater. Trans. B., 2014, vol. 45, pp. 1496–1509. https://doi.org/10.1007/s11663-014-0063-6.

W. Yan, W. Chen, Y. Yang, C. Lippold, and A. Mclean: Ironmaking Steelmaking., 2016, vol. 43, pp. 316–23. https://doi.org/10.1179/1743281215Y.0000000062.

H. Wang, P. Tang, G.H. Wen, and X. Yu: Ironmaking Steelmaking., 2011, vol. 38, pp. 369–73. https://doi.org/10.1179/1743281211Y.0000000011.

M.J. Toplis, D.B. Dingwell, and T. Lenci: Geochim. Cosmochim. Acta., 1997, vol. 61, pp. 2605–12. https://doi.org/10.1016/s0016-7037(97)00126-9.

S. Lee and D.J. Min: J. Am. Ceram. Soc., 2017, vol. 100, pp. 2543–52. https://doi.org/10.1111/jace.14787.

S. Huang, G. Jiang, K. Xu, F. Yoshida, and J. You: Metall. Mater. Trans. B., 2000, vol. 31B, pp. 1241–45. https://doi.org/10.1007/s11663-000-0011-5.

T. Wu, S. He, and Y. Liang: J. Non-Crystal. Solids., 2015, vol. 411, pp. 145–51. https://doi.org/10.1016/j.jnoncrysol.2014.12.030.

Z. Wang, S. Cai, M. Zhang, M. Guo, and Z. Zhang: Metall. Mater. Trans. B., 2017, vol. 48B, pp. 1–10. https://doi.org/10.1007/s11663-017-0924-x.

J. Kieffer and C.A. Angell: J. Chem. Phys., 1989, vol. 90, pp. 4982–91. https://doi.org/10.1063/1.456567.

P. Ganster, M. Benoit, W. Kob, and J.M. Delaye: J. Chem. Phys., 2004, vol. 120, pp. 10172–81. https://doi.org/10.1063/1.1724815.

T. Wu, W. Cui, B. Cao, Y. Zhu, and Q. Ouyang: Build. Environ., 2016, vol. 108, pp. 23–29. https://doi.org/10.1016/j.buildenv.2016.08.008.

T. Wu, Q. Wang, T. Yao, and S. He: J. Non-Cryst. Solids., 2016, vol. 435, pp. 17–26. https://doi.org/10.1016/j.jnoncrysol.2015.12.025.

K.C. Mills and B.J. Keene: Int. Mater. Rev., 1987, vol. 32, pp. 1–120. https://doi.org/10.1179/095066087790150296.

J.S. Choi, T.J. Park, and D.J. Min: J. Am. Ceram. Soc., 2020, vol. 104, pp. 140–56. https://doi.org/10.1111/jace.17432.

G.H. Kim and I. Sohn: J. Am. Ceram. Soc., 2019, vol. 102, pp. 6575–90. https://doi.org/10.1111/jace.16526.

H. Kim, W.H. Kim, J.H. Park, and D.J. Min: Steel Res. Int., 2010, vol. 81, pp. 17–24. https://doi.org/10.1002/srin.200900118.

H. Kim, W.H. Kim, I.I. Sohn, and D.J. Min: Steel Res. Int., 2010, vol. 81, pp. 261–64. https://doi.org/10.1002/srin.201000019.

G.H. Kim and I.L. Sohn: Effect of Al2O3 on the viscosity and structure of calcium silicate-based melts containing Na2O and CaF2. J. Non-Crystal. Solids., 2012, vol. 358, pp. 12–13.

H.S. Park, H. Kim, and I. Sohn: Metall. Mater. Trans. B., 2011, vol. 42B, pp. 324–30. https://doi.org/10.1007/s11663-011-9474-9.

S. Sridhar, K.C. Mills, O.D.C. Afrange, H.P. Lrz, and R. Carli: Ironmaking Steelmaking., 2000, vol. 27, pp. 238–42. https://doi.org/10.1179/030192300677534.

D.K. Belashchenko, I.E. Gopengauz, A.B. Grytsenko, and O.I. Ostrovskij: ISIJ Int., 1992, vol. 32, pp. 990–97. https://doi.org/10.2355/isijinternational.32.990.

R.N. Mead and G. Mountjoy: J. Phys. Chem. B., 2006, vol. 110, pp. 14273–78. https://doi.org/10.1021/jp0628939.

B.W.M. Thomas, R.N. Mead, and G. Mountjoy: J. Phys.: Condens. Matter., 2006, vol. 18, pp. 4697–4708. https://doi.org/10.1088/0953-8984/18/19/021.

Q. Mei, C.J. Benmore, J. Siewenie, J.K.R. Weber, and M. Wilding: J. Phys.: Condens. Matter., 2008, vol. 20, pp. 266–72. https://doi.org/10.1088/0953-8984/20/24/245106.

A.C. Hannon and J.M. Parker: J. Non-Cryst. Solids., 2000, vol. 274, pp. 102–09. https://doi.org/10.1016/S0022-3093(00)00208-8.

G.H. Kim, C.S. Kim, and I. Sohn: ISIJ Int., 2013, vol. 53, pp. 170–76. https://doi.org/10.2355/isijinternational.53.170.

D.R. Neuville, L. Cormier, and D. Massiot: Chem Geol., 2006, vol. 229, pp. 173–85. https://doi.org/10.1016/j.chemgeo.2006.01.019.

J. Gao, G. Wen, T. Huang, B. Bai, P. Tang, Q. Liu, and C. Jantzen: J. Am. Ceram. Soc., 2016, vol. 99, pp. 3941–47. https://doi.org/10.1111/jace.14444.

T.S. Kim and J.H. Park: ISIJ Int., 2014, vol. 54, pp. 2031–38. https://doi.org/10.2355/isijinternational.54.2031.

G.H. Kim and I. Sohn: Metall. Mater. Trans. B., 2014, vol. 45B, pp. 86–95. https://doi.org/10.1007/s11663-013-9953-2.

S. Shirayama, H. Aoki, Y. Yanaba, Y. Kim, and K. Morita: ISIJ Int., 2020, vol. 60, pp. 392–99. https://doi.org/10.2355/isijinternational.ISIJINT-2019-251.

Y. Kim and K. Morita: J. Non-Cryst. Solids., 2017, vol. 471, pp. 187–94. https://doi.org/10.1016/j.jnoncrysol.2017.05.034.

J. Yang, Y. Kim, and I. Sohn: J. Market. Res., 2021, vol. 10, pp. 268–81. https://doi.org/10.1016/j.jmrt.2020.12.028.

Acknowledgments

This research work was supported by the National Natural Science Foundation of China (Grant Nos. 51974132, U1738101, and 51974022) and Fundamental Research Funds for the Central Universities (Grant No. FRF-MP-20-17).

Conflict of interest

On behalf of all the authors, the corresponding author states that there are no conflicts of interest pertaining this study and manuscript

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, K., Han, Y., Yuan, Z. et al. Effect of MgO on the Viscosity and Structure of CaO-Al2O3-B2O3-Based Non-reactive Mold Flux. Metall Mater Trans B 53, 1504–1515 (2022). https://doi.org/10.1007/s11663-022-02460-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02460-2