Abstract

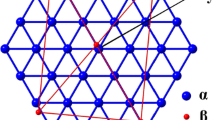

To study the grain morphology of Mg–Al alloy semisolid structure during the process of mechanical stirring, a multiple grains PF-LBM model (phase-field-lattice Boltzmann model) coupled with a rigid body rotation model was developed. In this study, an orientational field model was introduced to describe the orientation of different grains and it was determined that the growth of multiple grains with different orientations can be computed by only one-phase field function which improves the computing efficiency. The simulation results of the growth of two semisolid grains showed that the growth and coalescence representation can be simulated by the proposed model. Then, multiple grains growth of a Mg–Al alloy semisolid structure was successfully simulated using the developed model and the result is in good agreement with the experimental result.

Similar content being viewed by others

References

F.S. Pan, M.B. Yang, and X.H. Chen, J. Mater. Sci. Technol., 2016, 32, 1211-1221. DOI: 10.1016/j.jmst.2016.07.001

[2] F. Meng, S. Lv, Q. Yang, P. Qin, J. Zhang, K. Guan, Y. Huang, N. Hort, B. Li, X. Liu, and J. Meng, Alloy. Compd., 2019, vol. 795, pp. 436-445. DOI: 10.1016/j.jallcom.2019.04.346

[3] M. Modigell and A. Pola, M. Tocci, Metals, 2018, vol. 8, p. 245. DOI: 10.3390/met8040245

[4] S. Nafisi and R. Ghomashchi, Metals, 2019, vol. 9, p. 526. DOI: 10.3390/met9050526

L.N. Guan, L. Geng, H.W. Zhang, and L.J. Huang, Trans. Nonferrous Met. Soc. China, 2011, vol. 21, pp. S274-S297. DOI: 10.1016/S1003-6326(11)61590-2

[6] M. Asta, C. Beckermann, and A. Karma, Acta Mater., 2009, vol.57, pp. 941-971. DOI: 10.1016/j.actamat.2008.10.020

[7] T. Takaki, ISIJ Int., 2014, vol. 54, pp. 437-444. DOI: 10.2355/isijinternational.54.437

[8] D. Montiel and S. Gurevich, Acta Mater., 2014, vol. 77, pp. 183-190. DOI: 10.1016/j.actamat.2014.05.063

[9] N. Moelans, B. Blanpain, and P. Wollants, Calphad-Comput. Coupling Ph. Diagrams Thermochem, 2008, vol. 32, pp. 268-294. DOI: 10.1016/j.calphad.2007.11.003

[10] CK. Aidun and JR. Clausen, Annu. Rev. Fluid Mech., 2010, vol. 42, pp. 439-472. DOI: 10.1146/annurev-fluid-121108-145519

[11] D. Raabe, Model. Simul. Mater. Sci. Eng., 2004, vol. 12, pp. R13-R46. DOI: 10.1088/0965-0393/12/6/R01

[12] S. Sakane, T. Takaki, M. Ohno, Y. Shibuta, T. Shimokawabe, and T. Aoki, J. Cryst. Growth, 2018, vol. 483, pp. 147-155. DOI: 10.1016/j.jcrysgro.2017.11.029

C. Yang, Q.Y. Xu, and B.C. Liu, Rare Metals, 2020, 39, 147-155. DOI: 10.1007/s12598-019-01292-5

A. Zhang, J.L. Du, Z.P. Guo, Q.G. Wang, and S..M. Xiong, Metall. Mater. Trans. B 2018, 49, 3603-3615. DOI: 10.1007/s11663-018-1418-1

[15] WZ. Sun, Y. Xie, R. Yan, SD. Ma, HB. Dong, and T. Jing, Metall. Mater. Trans. B-Proc. Metall. Mater. Proc. Sci., 2019, vol. 50, pp. 2487-2497. DOI: 10.1007/s11663-019-01669-y

A. Zhang, S.X. Meng, Z.P. Guo, J.L. Du, Q.G. Wang, and S.M. Xiong, Metall. Mater. Trans. B 2019, 50, 1514-1526. DOI: 10.1007/s11663-019-01549-5

[17] T. Takaki, R. Rojas, S. Sakane, M. Ohno, Y. Shibuta, T. Shimokawabe, and T. Aoki, J. Cryst. Growth, 2017, vol. 474, pp. 146-153. DOI: 10.1016/j.jcrysgro.2016.11.099

[18] R. Rojas, T. Takaki, and M. Ohno, J. Comput. Phys., 2015, vol. 298, pp. 29-40. DOI: 10.1016/j.jcp.2015.05.045

X.B. Qi, Y. Chen, X.H. Kang, D.Z. Li, and T.Z. Gong, Sci. Rep., 2017, 7, 45770. DOI: 10.1038/srep45770

S.X. Meng, A. Zhang, and Z.P. Guo, Comput. Mater. Sci., 2020, 184, 109784. DOI: 10.1016/j.commatsci.2020.109784

[21] L. Ratkai, T. Pusztai, and L. Granasy, npj Comput. Mater., 2019, vol. 5, p. 113. DOI: 10.1038/s41524-019-0250-8

[22] S. Sakane, T. Takaki, M. Ohno and Y. Shibuta, Comput. Mater. Sci. 2019, vol. 164, pp. 39-45. DOI: 10.1016/j.commatsci.2019.03.047

S. Luo, P. Wang, W.L. Wang, and M.Y. Zhu, Metall. Mater. Trans. B 2020, 51, 2268-2284. DOI: 10.1007/s11663-020-01925-6

[24] T. Takaki, R. Sato, R. Rojas, M. Ohno, and Y. Shibuta, Comput. Mater. Sci., 2018, vol.147, pp. 124-131. DOI: 10.1016/j.commatsci.2018.02.004

[25] S. Sakane, T. Takaki, M. Ohno, Y. Shibuta, and T. Aoki, Comput. Mater. Sci., 2020, vol.178, p. 109639. DOI: 10.1016/j.commatsci.2020.109639

X. Zhang,Y. Wang, D.R. Liu, Z.S. Ji, H.Y. Xu, M.L. Hu, and P.X. Cui, J. Cryst. Growth, 2020, 543, 125704. DOI: 10.1016/j.jcrysgro.2020.125704

T. Suzuki, M. Ode, and S.G. Kim, J. Cryst. Growth, 2002, 237–239, 125–131. DOI: 10.1016/S0022-0248(01)01891-7

[28] JJ. Li, JC. Wang, Q. Xu, and GC. Yang, Acta Mater., 2007, vol. 55, pp. 825-832. DOI: 10.1016/j.actamat.2006.07.044

[29] C. Beckermanna, H.J. Diepersb, I. Steinbachb, A. Karmac, and X. Tonga, J. Comput. Phys., 1999, vol. 154, pp. 468-496. DOI: 10.1006/jcph.1999.6323

[30] JA. Warren, R. Kobayashi, and AE. Lobovsky, Acta Mater., 2003, vol. 51, pp. 6035-6058. DOI: 10.1016/S1359-6454(03)00388-4

[31] E. Semma, M. El Ganaoui, and R. Bennacer, Int. J. Therm. Sci., 2008, vol. 47, pp. 201-208. DOI: 10.1016/j.ijthermalsci.2007.02.010

[32] S. Lee, Y. Li, J. Shin, and J. Kim, Comput. Phys. Commun., 2017, Vol. 216, pp. 84-94. DOI: 10.1016/j.cpc.2017.03.005

Acknowledgements

This work was supported by the Natural Science Foundation of China (Grant Nos. 51574100 and 51704087), the Natural Science Foundation of Heilongjiang Province (Grant No. LH2020E083) and the National key research and development program (Grant No. 2019YFB2006500).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted January 25, 2021, accepted April 25, 2021.

Rights and permissions

About this article

Cite this article

Zhang, X., Wang, Y., Ji, Z. et al. Simulations of Multiple Grains Growth of Mg–Al Alloy Semisolid Structure by Phase-Field-Lattice Boltzmann Simulation. Metall Mater Trans B 52, 2441–2449 (2021). https://doi.org/10.1007/s11663-021-02204-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02204-8