Abstract

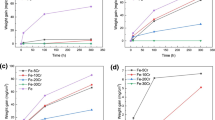

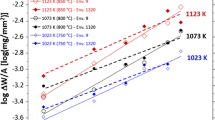

In this work, the kinetics of decarburization and demanganization of Fe–15Mn–1C alloy by bubbling mixtures of Ar–O2 into the melt at 1823 K was studied. Experiments were conducted at total gas flow rates of 200 and 300 Nml/min and gas mixtures of Ar containing 6.7 to 20 pct O2. Increasing the gas flow rate and oxygen in the gas mixture resulted in higher overall rates of decarburization and demanganization. However, the experiments with the lowest oxygen concentration were the most efficient in terms of oxygen utilization for decarburization. The ratio of manganese loss to decarburization was found to be controlled by the relative mass transport of manganese and carbon in the metal. Based on the estimated mass transfer coefficient for either carbon or manganese, the reaction time for each bubble was estimated to be 0.001 seconds which is about 1 pct of the residence time of the bubble in the liquid. Although the initial competition for oxygen between manganese and carbon was controlled by relative mass transport rates, this work found no evidence that manganese and carbon repartitioned towards the equilibrium over the remaining lifetime of the bubble.

Similar content being viewed by others

References

B. C. De Cooman, K. Chin, and J. Kim: in New Trends and Developments in Automotive System Engineering, InTech, Rijeka, 2011, pp. 101–28.

2 R. Elliott, K. Coley, S. Mostaghel, and M. Barati: JOM, 2018, vol. 70, pp. 680–90.

3 O. Bouaziz, S. Allain, C.P. Scott, P. Cugy, and D. Barbier: Curr. Opin. Solid State Mater. Sci., 2011, vol. 15, pp. 141–68.

POSCO, POSCO Steel Plates, Pohang, South Korea, unpublished research, 2014.

POSCO, New Materials: High Mn Steels, Pohang, South Korea, unpublished research, 2015.

Thyssenkrupp, Precision Steel, Precidur ® X40MnCrAIV 19-2 HY, Product Information for Hot-Rolled Precision Strip Made in Hohenlimburg, Germany, Hohenlimburg, unpublished research, 2019.

W. Dresler: in Steelmaking Conference Proceedings, 1989, pp. 13–20.

D.S. Kozak and L.R. Matricardi.: Iron Steelmak., 1981, vol. 8, pp. 28–31.

9 T. Germershausen, J. Bader, J. Reichel, U. Gerike, and S.M.S.S. Ag: in The thirteenth International Ferroalloys Congress Efficient technologies in ferroalloy industry, Almaty, Kazakhstan, 2013, pp. 335–46.

10 T. Ohno and T. Nishida: Tetsu-to-Hagane, 1977, vol. 63, pp. 2094–9.

11 R.J. Fruehan: Ironmak. Steelmak., 1976, vol. 3, pp. 153–8.

12 N. Andersson, A. Tilliander, L. Jonsson, and P. Jönsson: Steel Res. Int., 2012, vol. 83, pp. 1039–52.

13 J. Wei, H. Zhu, Q. Jiang, G. Shi, H. Chi, and H. Wang: ISIJ Int., 2010, vol. 50, pp. 1347–56.

G.S. Rao and D.G.C. Robertson: in Advanced Processing of Metals And Minerals, The Minerals, Metals & Materials Society (TMS), 2006, pp. 325–42.

15 T.D. Roy and D.G.C. Robertson: Ironmak. Steelmak., 1978, vol. 5, pp. 198–206.

16 T.D. Roy, D.G.C. Robertson, and J.C.C. Leach: Ironmak. Steelmak., 1978, vol. 5, pp. 207–10.

17 J.-H. Wei and D.-P. Zhu: Metall. Mater. Trans. B, 2002, vol. 33, pp. 111–19.

18 S. Asai and J. Szekely: Metall. Trans., 1974, vol. 5, pp. 651–7.

19 J. Szekely and S. Asai: Metall. Trans., 1974, vol. 5, pp. 1573–80.

20 J. Reichel and J. Szekely: Iron Steelmak., 1995, vol. 22, pp. 41–8.

21 R.J. Fruehan: Ironmak. Steelmak., 1976, vol. 3, pp. 33–37.

22 W.A. Krivsky: Metall. Trans., 1973, vol. 4, pp. 1439–47.

23 J.M. Saccomano, R.J. Choulet, and J.D. Ellis: J. Met., 1969, vol. 21, pp. 59–64.

24 R.J. Fruehan: Met. Trans. B, 1975, vol. 6, pp. 573–8.

25 K. Yamamoto, T. Mimura, S. Ito, and T. Onoye: Tetsu-to-Hagane, 1986, vol. 72, pp. 1034–46.

26 Y.E. Lee and L. Kolbeinsen: ISIJ Int., 2005, vol. 45, pp. 1282–90.

27 B.-D. You: J. Korean Institue Met. Mater., 1995, vol. 33, pp. 1508–13.

28 B.-D. You, J. Han, and J. Pak: Steel Res., 2000, vol. 71, pp. 22–6.

29 B.-D. You, K.-Y. Park, J.-J. Pak, and J.-W. Han: Met. Mater., 1999, vol. 5, pp. 395–9.

30 B.-D. You, B.-W. Lee, and J.-J. Pak: Met. Mater., 1999, vol. 5, pp. 497–502.

31 E.T. Turkdogan, P. Grieveson, and L.S. Darken: J. Am. Chem. Soc., 1963, vol. 67, pp. 1647–54.

32 H. Liu, J. Liu, J. Schenk, F.M. Penz, L. Sun, R. Zhang, and Z. An: Metall. Mater. Trans. B, 2020, vol. 51, pp. 756–62.

A. Rafiei, G.A. Irons, and K.S. Coley: Steel Res. Int., https://doi.org/10.1002/srin.202000480.

34 F. Oeters, K. Koch, R. Scheel, and U. Noelle: Arch Eisenhuettenwes, 1977, vol. 48, pp. 475–80.

35 S.K. Dey and D.N. Ghosh: Metall. Mater. Trans. B, 1976, vol. 7, pp. 43–8.

R. Tsujin, M. Hirai, T. Ohno, N. Ishiwata, and T. Inoshita: ISIJ Int., 1989, vol. 29, pp. 291–9.

37 Y.E. Lee: Metall. Mater. Trans. B, 1998, vol. 29, pp. 397–403.

38 G.F. Versteeg, P.M.M. Blauwhoff, and W.P.M. VAN Swaaij: Chem. Eng. Sci., 1987, vol. 42, pp. 1103–19.

39 J. Wei and H. Zuo: Steel Res. Int., 2007, vol. 78, pp. 863–75.

40 T. Yagi, Y. Ono, and M. Ushijima: Tetsu-to-Hagane, 1970, vol. 56, pp. 1640–45.

41 Y. Ono and S. Matsumoto: Trans. JIM, 1975, vol. 16, pp. 415–22.

42 H. Nomura and K. Mori: Tetsu-to-Hagane, 1969, vol. 55, pp. 1134–41.

43 D. Goldberg and G.R. Belton: Metall. Trans., 1974, vol. 5, pp. 1643–8.

Y. Ono: Tetsu-to-Hagane, 1977, vol. 63, 1229–34.

45 Y. Wanibe, S. Takai, T. Kojima, and H. Sakao: Trans. Iron Steel Inst. Japan, 1980, vol. 20, pp. 783–89.

46 F.P. Calderon, N. Sano, and Y. Matsushita: Metall. Mater. Trans. B, 1971, vol. 2, pp. 3325–32.

T. Saito, Y. Kawai, K. Maruya, and M. Maki: Sci. Rep. Res. Inst. Tohoku Univ. Ser. A Phys. Chem. Metall., 1959, vol. 11, pp. 401–10.

48 A. Majdic, D. Graf, and H. Schenck: Arch. für das Eisenhüttenwes, 1969, vol. 40, pp. 627–30.

49 J.H. Park, D.S. Kim, and S. Lee: 2005, vol. 36, pp. 67–73.

50 O.K. Tokovoi, A. V Tokarev, A.N. Volkadaev, S.N. Prokofev, and A.N. Komarov: Izvvestiya Ross. Akad. Nauk. Met., 1995, vol. 3, pp. 10–4.

A. Rafiei, G.A. Irons, and K.S. Coley: Metall. Mater. Trans. B, Accepted for publication.

Acknowledgments

The authors gratefully acknowledge financial support from the Natural Sciences and Engineering Research Council of Canada. Additional thanks go to ArcelorMittal Dofasco, Stelco, Praxair, and Hatch Ltd. for in-kind support and technical expertise.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 5, 2020; accepted April 6, 2021.

Rights and permissions

About this article

Cite this article

Rafiei, A., Irons, G.A. & Coley, K.S. Kinetics of Decarburization and Manganese Loss from Fe–15Mn–1C Alloy by Bubbling of Argon–Oxygen Gas Mixtures. Metall Mater Trans B 52, 2375–2385 (2021). https://doi.org/10.1007/s11663-021-02180-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02180-z