Abstract

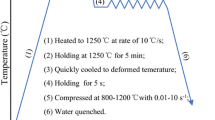

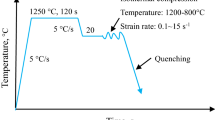

The deformation mechanism and constitutive equation of Ti-Mo steel in the mushy zone were investigated through high-temperature compression deformation. Nonlinear fitting and polynomial fitting were used to build a precise constitutive model. The law of microstructure evolution was also researched. During the deformation of Ti-Mo steel in the mushy zone, the liquid phase was squeezed to the edge, and macro separation between the solid and liquid occurred after deformation. The extent of dynamic crystallization in Ti-Mo steel increased with increasing strain rate, which is quite different from the dynamic recrystallization occurring during deformation in the solid region. The critical condition for dynamic recrystallization decreased and the grain refinement degree increased due to the return temperature effect of the liquid between solid particles. The prediction accuracy of the modified Fields–Backofen (FB) model with a liquid-phase adjustment factor was compared with that of the Arrhenius model with a liquid-phase adjustment factor. The results showed that the modified FB model had low prediction accuracy. The Arrhenius model with a liquid-phase adjustment factor was revised according to different strain rates. The revised model had higher prediction accuracy and was suitable for describing the metal rheology in the mushy zone of Ti-Mo steel, with accuracy of approximately 90 pct.

Similar content being viewed by others

References

1.F. J. Zerilli and R. W. Armstrong: J. Appl. Phys., 1987, vol. 54, pp1816-25.

2.J. M. Cabrera, A. A. Omar, J. J. Jonas and J. M. Prado: Metall. Mater. Trans. A, 1997, vol.28, pp 2233-44.

3.C. Ji, Z. L. Wang, C. H. Wu and M. Y. Zhu: Metall. Mater. Trans. B, 2018, vol. 49, pp767-82.

4.M. A. Davinci, D. Samantaray, U. Borah, S. K. Albert and A. K. Bhaduri: Mater. Des. 2015, vol. 88: 567-76.

5.Y. C. Lin and G. Liu: J. Mater. Sci. Eng. A. 2009, vol. 523, pp. 139-44.

J. Luo, M. Q. Li and D. W. Ma: J. Mater. Sci. Eng. A. 2012, vol. 532, pp. 548-57.

7.C. Ji, S. Luo and M.Y. Zhu: ISIJ Int., 2014, vol. 54, pp. 504-10.

8.C. H. Wu, C. Ji and M. Y. Zhu: J. Mater. Process. Technol., 2019, vol. 271, pp. 651-59.

G. R. Johnson and W. H. Cook: High strain-rates and high temperatures Proc 7th Int. Symp. Ballistics., 1983, vol. 547, pp. 54–417.

F. J. Zerilli and R.W. Armstrong: Appl. Phys., 1987, vol. 62, pp. 1816-25.

11.C. M. Sellars and W. J. Mctegart: Acta. Metall., 1966, vol.14, pp.1136-8.

12.D. Samantaray, S. Mandal, U. Borah, A. K. Bhaduri and P. V. Sivaprasad: Mater. Sci. Eng. A., 2009, vol.526, pp.1-6.

13.D. Samantaray, S. Mandal and A. K. Bhaduri: Comput. Mater. Sci., 2009, vol.47, pp.568-76.

14.Z. J. Pu, K. H Wu, J. Shi and D. Zou: Mater. Sci. Eng. A., 1995, vol.192, pp.780-7.

15.Y. C. Lin, M. S. Chen and J. Zhong: Comput. Mater. Sci., 2008, vol.42, pp.470-7.

16.J. J. Wang, A. B. Phillion and G. M. Lu: J. Alloys Compd., 2014, vol. 609, pp. 290-5.

17.L. H. Qi, Z. J. Wang, J. M. Zhou, L. Z. Su and H. J. Li: Compos. Sci. Technol., 2011, vol.71, pp. 955-61.

18.C. G. Kang and H. K. Jung: Int. J. Mech. Sci., 1999, vol. 41, pp. 1423-45.

19.Y. Xu, C. Chen, J. B. Jia, X. X. Zhang, H. H. Dai and Y. Yang: J. Alloys Compd., 2018, vol. 748, pp. 694-705.

20.G. Chen, Y. F. Lin, S. J. Yao, F. Han, B. Wei and Y. M. Zhang: J. Alloys Compd., 2016, vol. 674, pp. 26-36.

21.Q. Tang, M. Y. Zhou, L. L. Fan, Y. W. Zhang, G. F. Quan and B Liu: Vacuum, 2018, vol. 155 pp. 476-489.

22.X. H. Chen and H. Yan: J. Alloys Compd., 2017, vol.708, pp. 751-62.

23.H. Li, C. Miao, L. Q. Niu, K. Huang and Q. Zhang: J. Alloys Compd., 2021, vol.854 157124.

24.S. J. Qu, A. H. Feng, L. Geng, Z.Y. Ma and J. C Han: Scr. Mater., 2007, vol. 56: pp.951-54.

25.C. Q. Zhao and R. B. Song: Mater. Des., 2014, vol. 59: pp.502-8.

G. R. Ebrahimi, H. Keshiri, A. Momeni, M. Mazinani: Mater. Sci. Eng. A, 2011, 528: 7488-93.

D. S. Fields, W. A. ASTM Proceedings American Society for Testing and Materials, 1957, vol. 57: pp. 1259–72.

28.L. C. Tsao, Y. T. Huang and K. H. Fan: Mater. Des., 2014, vol. 53: pp.865-69.

29.Y. C. Lin, M. S. Chen and J. Zhong: Comput. Mater. Sci., 2008, vol.42, pp. 470-77.

30.G. Bao and Z. Lin: Acta Mater., 1996, vol. 44, pp.1011-19.

31.K. Higashi, T. G. Nieh, M. Mabuchi and J. Wadworth: Scr. Metall. Mater., 1995, vol. 32, pp. 1079-84.

Acknowledgments

The present work was financially supported by the National Natural Science Foundation of China (51974078, U1708259 and U20A20272), the Fourth Period Science and Technology Key Project of Panxi Experimental Area, the Talent Project of Revitalizing Liaoning (XLYC1907176 and 1802032), and the Fundamental Research Funds for the Central Universities of China (N2025012, N2125018, and N2125007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 16, 2020; March 30, 2021.

Rights and permissions

About this article

Cite this article

Chen, T., Zhou, Q., Ji, C. et al. Compression Deformation Mechanism and Constitutive Equation of Ti-Mo Steel in the Mushy Zone. Metall Mater Trans B 52, 2194–2209 (2021). https://doi.org/10.1007/s11663-021-02169-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02169-8