Abstract

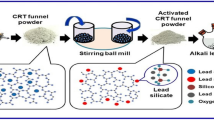

Cathode ray tube (CRT) waste funnel glass as a past energy material is a hazardous waste that contains toxic lead oxide, presenting a great environmental challenge worldwide. There is a significant need for an effective treatment method to facilitate safe disposal of CRT. In this work, a novel and simple method to remove lead oxide and recycle metallic lead was developed by PbO vapor vacuum reduction (PVVR) process. Use of vacuum thermal process allows the successful removal of lead oxide from waste CRT funnel glass and recycling of PbO. To obtain metallic Pb and remove the volatile potassium and sodium elements, the PbO vapor vacuum reduction (PVVR) process was designed and implemented. The optimum reduction temperature and holding time for lead recovery were 1573 K and 120 minutes, respectively. Under this condition, more than 98 pct of lead can be removed from waste funnel glass and the Pb content in parent glass was successfully reduced to 0.38 pct. The metallic Pb microspheres with 99.36 pct purity were obtained and the Pb leaching concentration of residual glass was 1.67 mg/L as measured by the Toxicity Characteristic Leaching Procedure (TCLP) test. Additionally, the charcoal layers have a greater than 85 pct K adsorption effect and do not contaminate residual glass. Then, luminescent Tb3+ glass as an energy material using residual glass was greatly luminescence performance. Overall, this work presents a simple and effective process for the detoxification and utilization of waste CRT funnel glass as well as the recovery of Pb by vacuum metallurgy technology.

Similar content being viewed by others

References

1. M.L. Socolof, J.G. Overly,. J.R. Geibig, J. Clean Prod., 2005, vol. 13, pp.1281-1294.

Statica, Global TV Shipments Forecast From 2009 to 2016, by Technology (in million units). http://www.statista.com/statistics/260367/globaltv-shipments-forecast/.

N. Singh, J.H. Li, X.L. Zeng, Waste Manag., 2016, vol. 57, pp. 187-197.

Y.C. Jang, T.G. Townsend, J. Environ. Sci. Technol., 2003, vol.7, pp. 4778-4784.

5. M. Yu, L. Liu, J. H. Li, Procedia Environmental Sciences, 2016, vol. 31, pp. 887-896.

F. Mear, P. Yot, M. Cambon, M. Ribes, Waste Manage., vol. 26, pp. 1468–76.

C. Baldé, F. Wang, R. Kuehr, J. Huisman, The global e-waste monitor- 2014.United Nations University, IAS–SCYCLE, Bonn, Germany. 2015.

8. J. R. Gregory, M. C. Nadeau, R.E. Kirchain, J. Environ. Sci. Technol. 2009, vol. 43, pp. 9245-9251.

F. Wang, B. Hu. A Forecast of the Amount of Recovery in Obsolete CRT Leaded Glass. Tianjin University of Technology, 2016.

10. Q.B. Song, Z.S. Wang, J.H. Li, et al., Waste Manage., 2012, vol. 32, pp. 1926-1936.

11. F. Andreola,L Barbieri,A. Corradi. I Lancellotti, J. Eur. Ceram. Soc., 2007, vol. 27, pp. 1623-1629.

S. Heart, Clean Soil Air Water, 2008, vol. 36, pp. 19-24.

C. Mengjun, Research on harmless treatment technology of waste CRT glass. 2009, DOI: http://159.226.240.226/handle/311016/304.

14. M.F. Xing, F.S. Zhang, J. Hazard. Mater., 2011, vol.194, pp. 407–413.

15. M.F. Xing, Y.P. Wang, J. Li, J. Hazard. Mater., 2016, vol. 305, pp. 51-58.

16. M.F. Xing, Z.G. Fu, Y.P. Wang, L J. Hazard Mater., 2017, vol. 322, pp. 479-487.

17. C.L. Zhang, L.L. Zhuang, W.Y. Yuan. Hydrometallurgy. 2016, vol. 165, pp. 312-317.

18. Takashi Okada, Susumu Yonezawa, Waste Manag., 2014, vol. 34, pp. 1470-1479.

19. Takashi Okada, Fumihiro Nishimura, Waste Manag., 2015, vol. 45pp. 343-350.

20. B. Aseel, A.L. Zubaid, Kadum Muttar Shabeeb, Aynoor Ibrahim Ali, Energy Procedia. 2017, vol. 119, pp. 680-692.

21. Giada Kyaw Oo D’Amore, Marco Caniato, Andrea Travan, J. Clean Prod., 2017, vol. 165, pp. 1306-1315.

N. Glass, Recycling CRTs from televisions & computer screens. http://www.nulifeglass.com/. 2013.

S. Kuusakoski, 2014. http://www.sweeepkuusakoski.co.uk/. UK department of the environment, 1995. metal manufacturing, refining and finishing works: lead works. department of the environment (DOE), UK.

W.W. Hu, X.D. Xu, Nonferrous Metals (Extractive Metallurgy). 2015, vol. 8, pp. 24–26.

J.Q. An, K. Huang, Y. Zhao, H. Ma, T.K. Wang, R.P. Hu, K.Y. Sun, X.L. Wang, Nonferrous Metals (Extractive Metallurgy). 2016, vol. 18(3), pp. 10–12.

Y. Wang, J. Zhu, J. Hazard Mater., 2012, pp. 215–216, 90–97.

27. Takashi Okada, Susumu Yonezawa, Waste Manage., 2013, vol. 33 (8), pp.1758-1763.

28. M.J. Chen,, F.S. Zhang, J. Zhu, J. Hazard. Mater., 2010, vol. 182 (1), pp. 45-49.

29. P.G. Yot, F.O. Méar, J. Hazard. Mater., 2009, vol. 172, pp. 117-123.

30. F. Méar, P. Yot, M. Ribes, Mater. Lett., 2006, vol. 60, pp. 929-934.

31. J.F. Lv, H.Y. Yang, Z.N. Jin, Z.Y. Ma, Y. Song, Waste Manage., 2016, vol. 57, pp. 198-206.

32. J.F. Lv, H.Y. Yang, Z.N. Jin, M.L. Zhao, Waste Management., 2018, vol. 76, pp. 687–696.

33. B. Hu, W.L. Hui, Waste Manag., 2017, vol. 67, pp. 253-258.

34. B. Hu, W.L. Hui, J. Hazard. Mater., 2018, vol. 343, pp. 220-226.

G. Grause, K. Takahashi, T. Kameda, T. Yoshioka, Thermochim. Acta. 2014, vol. 596, pp. 596.

G. Grause, T. Yamamoto, T. Kameda, J. Environ. Sci. Teachnol., 2014, vol. 11, pp. 959-966.

37. A. Erzat, F.S. Zhang, Environ. Technol., 2014, vol. 35 (21–24), pp. 2774–2780.

38. M.J. Chen, F.S. Zhang, J. Zhu, J. Hazard. Mater., 2009, vol. 161, pp. 1109–1113.

39. N. Singh, J.H. Li, J. Clean Prod., 2017, vol. 148, pp.103-110.

40. E. Bernardo, J Eur Ceram Soc., 2007, vol. 27, pp. 2415–2422.

41. E. Bernardo, R. Cedro, M. Florean, S. Hreglich, Ceram. Int., 2007, vol.33, pp. 963–968.

42. H.R. Fernandes, F. Andreola, L. Barbieri, I. Lancellotti, M.J. Pascual, J.M. Ferreira, Ceram. Int., 2013, vol. 39, pp. 9071–9078.

43. H.R. Fernandes, D.D. Ferreira, F. Andreola, I. Lancellotti, L. Barbieri,, J.M. Ferreira, Ceram. Int., 2014, vol.40, pp. 13371-13379.

B. Mary, S. Ogundiran, S. Ikpeni, Enakerakpo, Afr. J. Pure Appl. Chem., 2018, vol. 12(6), pp. 42-49.

Y. Zhou, C.-Z. Liao, and K. Shih, ACS Sustain. Chem. Eng. 2018.

46. M. Matsuno, K. Tomoda, T. Nakamura, Mater Trans. 2003, vol. 44, pp. 2481-2488.

47. W. J. Kroll, Trans. Electrochem. Soc., 1940, vol. 78, pp. 35-47.

48. J. Kang, T. H. Okabe, Metallurgical & Materials Transactions B, 2013, vol. 44(3), pp. 516-527.

49. F. Mear, P. Yot, M. Cambon, M. Ribes, Waste Manage., 2006, vol. 26, pp. 1468-1476.

50. Z.Y. Fu, P.B. Xu, Y.S. Yang, C. Li, H. Lin, Q.M. Chen, G.P. Yao, Y.Y. Zhou, Fanming Zeng, Journal of Luminescence. 2018, vol. 196, pp. 368–372.

Y. Dai and B. Yang: Vacuum Metallurgy of Nonferrous Metals, Metallurgical Industry Press, 2009.

Acknowledgments

This work was supported by National Science Foundation of China (No. 51734006), Science and Technological Talent Cultivation Plan of Yunnan Province, China (No. 2017HB009), the Cultivating Plan Program for the Leader in Science and Technology of Yunnan Province under Grant (No. 014HA003), and the Program for Nonferrous Metals Vacuum Metallurgy Innovation Team of Ministry of Science and Technology under Grant (No. 2014RA4018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 15, 2020; accepted February 26, 2021.

Rights and permissions

About this article

Cite this article

Wang, F., Xu, B., Yang, B. et al. Pb Recovery of Waste Cathode Ray Tube Funnel Glass by PbO Vapor Vacuum Reduction (PVVR) Process and the Feasibility of Luminescent Glass Production. Metall Mater Trans B 52, 2294–2306 (2021). https://doi.org/10.1007/s11663-021-02139-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02139-0