Abstract

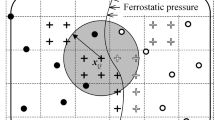

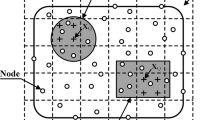

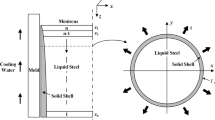

When solving the coupled thermal-mechanical problem of the metal solidification, the mesh-based numerical methods suffer from the inconsistency of mesh lines and curved boundaries. Furthermore, the mesh should be continually reconstructed to comply with the interface when dealing with the moving boundary such as phase transition, which brings great difficulties to the numerical calculation. Based on the plane stress assumption, the present work establishes a two-dimensional thermo-elastic-plastic calculation model for continuous casting round billets using the Element-Free Galerkin method, and the correction scheme of elastoplastic transition region has been explored. The results show that the correction scheme has a slight effect on magnitude of the equivalent stress and no impact on the subsequent plastic deformation zone. The elastoplastic transition region of shell surface appears in the range of 100 to 200 mm below the meniscus, and the averaged plastic stress is about 2.27 times of the elastic stress at the mold outlet. Near the interface region of liquid–solid phase exhibits an elastic deformation behavior, while far from the interface region appears plastic deformation in which the elastic stress remains invariable. The Element-Free Galerkin method is discretized by a series of arbitrary nodes, which exhibits high accuracy and great flexibility in dealing with moving interface problems. It provides a powerful approach to calculate and analyze the heat transfer/mechanical behavior with complex geometric boundaries such as round billet, chamfered billet, and beam blank.

Similar content being viewed by others

References

F. Du, X. Wang, X. Han, J. Xu, and M. Yao: Ironmak. Steelmak., 2018, vol. 45, pp. 350-55.

S. Koric, L.C. Hibbeler, R. Liu, and B.G. Thomas: Numer. Heat Transfer B, 2010, vol. 58, pp. 371-92.

S. Koric, and B.G. Thomas: Int. J. Numer. Methods Eng., 2006, vol. 66, pp. 1955-89.

G.R. Liu: Mesh Free Methods Moving Beyond the Finite Element Method, 1st ed., CRC Press LLC, Boca Raton, FL, 2002, pp. 53-265.

G.R. Liu and Y.T. Gu: An Introduction to Meshfree Methods and Their Programming, 1st ed., Springer, Dordrecht, 2005, pp. 54-111.

M. Alizadeh, S.A.J. Jahromi, and S.B. Nasihatkon: ISIJ Int., 2010, vol. 50, pp. 411-17.

R. Vertnik, and B. Šarler: Int. J. Cast. Metals Res., 2009, vol. 22, pp. 311-13.

R. Vertnik, and B. Šarler: Eng. Anal. Bound. Elem., 2014, vol. 45, pp. 45-61.

L. Zhang, Y.M. Rong, H.F. Shen, and T.Y. Huang: J. Mater. Process. Technol., 2007, vol. 192, pp. 511-17.

L. Zhang, Y.M. Rong, H.F. Shen, and T.Y. Huang: Int. J. Intell. Syst. Technol. Appl., 2008, vol. 4, pp. 177-87.

J.C. Álvarez-Hostos, A.D. Bencomo, and E.S. Puchi-Cabrera: J. Therm. Stresses, 2018, vol. 41, pp. 160-81.

L.Q. Cai, X.D. Wang, N. Wang, and M. Yao: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 236-46.

L.Q. Cai, X.D. Wang, M. Yao, and Y. Liu: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 1113-26.

R. Vaghefi, A. Nayebi, and M.R. Hematiyan: Acta Mech., 2018, vol. 229, pp. 4375-92.

L. Zhang, H.F. Shen, Y.M. Rong, and T.Y. Huang: Mater. Sci. Eng. A, 2007, vol. 466A, pp. 71-78.

J.C. Álvarez-Hostos, E.S. Puchi-Cabrera, and A.D. Bencomo: Steel Res. Int., 2017, vol. 88, pp. 1600019.

J.C. Álvarez-Hostos, A.D. Bencomo, E.S. Puchi-Cabrera, and I.M. Figueroa-Poleo: Int. J. Cast. Metals Res., 2018, vol. 31, pp. 47-55.

R. Vaghefi, M.R. Hematiyan, A. Nayebi, and A. Khosravifard: Eng. Anal. Bound. Elem., 2018, vol. 89, pp. 10-24.

B. Lally, L. Biegler, and H. Henein: Mater. Trans. B, 1990, vol. 21, pp. 761-770.

H.B. Yin, M. Yao, and D.C. Fang: ISIJ Int., 2006, vol. 46, pp. 539-45.

K. Kim, T. Yeo, K.H. Oh, and D.N. Lee: ISIJ Int., 1996, vol. 36, pp. 284-89.

A. Moitra, and B.G. Thomas: Steelmaking Conf. Proc., ISS/AIME, 1993, vol. 76, pp. 657-67.

Acknowledgments

This work is supported by the National Natural Science Foundation of China [51974056/51474047/51704073]; the Fundamental Research Funds for the Central Universities and the Key Laboratory of Solidification Control and Digital Preparation Technology (Liaoning Province) is also gratefully acknowledged. Part of this work was performed using computational resources from Supercomputing Center of Dalian University of Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 13, 2020; accepted December 15, 2020.

Rights and permissions

About this article

Cite this article

Cai, L., Wang, X., Wei, J. et al. Element-Free Galerkin Method Modeling of Thermo-Elastic-Plastic Behavior for Continuous Casting Round Billet. Metall Mater Trans B 52, 804–814 (2021). https://doi.org/10.1007/s11663-020-02054-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-02054-w