Abstract

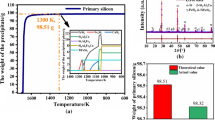

Metallurgical grade silicon (MG-Si) contains iron (Fe) as its main impurity, where phosphorus (P) is occasionally enriched in the FeSi2Ti phase. Based on this phenomenon, the precipitation superiority of P in the silicon-iron-titanium (Si-Fe-Ti) phase was verified by Si-5Fe and Si-3Fe-2Ti (wt pct) alloy refining for MG-Si. Microscopic characterization showed that P enrichment in the Si-Fe-Ti phase was more than in the Si-Fe phase. Thermodynamically, FeTiP phase is more stable than Fe3P. Dynamically, Fe and Ti will increase the solubility of each other in the melt because the activity interaction coefficient of Fe and Ti is 5.7027. Therefore, during the solidification of the Si-Fe-Ti melt, the enhanced precipitation of Fe and Ti promotes the formation and co-precipitation of the Si-Fe-Ti and FeTiP phases. With acid leaching, the phosphorus removal efficiencies from MG-Si, the Si-Fe alloy, and Si-Fe-Ti alloy were 12.33, 39.15, and 71.20 pct, respectively, which again verify the distribution characteristics of P in different samples and its mechanistic analysis.

Similar content being viewed by others

References

C. D. Thurmond and M. Kowalchik: Bell Labs Tech. J., 2013, vol. 39, pp. 169-204.

K. Suzuki, K. Sakaguchi, T. Nakagiri and N. Sano: J. Jpn. Inst. Met, 1990, vol. 54, pp. 161-167.

N. Yuge; K. Hanazawa, K. Nishikawa and H. Terashima: J. Jpn. Inst. Met, 1997, vol. 61, pp. 1086-1093.

C. Zhang, K. Wei, D. Zheng, W. Ma and Y. Dai: Vacuum, 2017, vol. 146, pp. 159-163.

Y. Meteleva-Fischer, Y. X. Yang, R. Boom, B. Kraaijveld and H. Kuntzel: JOM, 2012, vol. 64, pp. 957-967.

S. Ueda, K. Morita and N. Sano: Metal. Mat. Trans. B, 1997, vol. 28, pp. 1151-1155.

T. Shimpo, T. Yoshikawa and K. Morita: Metal. Mat. Trans. B, 2004, vol. 35, pp. 277-284.

W. Yan, Y. Yang, W. Chen, M. Barati and A. Mclean: Vacuum, 2016, vol. 135, pp. 101-108.

Z. Ge, Z. Wang, L. Sun, K. Xie and W. Ma: Chinese Journal of Process Engineering, 2016, vol. 16, pp. 1002-1008.

M. D. Johnston and M. Barati: Sep. Purif. Technol., 2013, vol. 107, pp. 129-134.

J. Li, Z. Guo, J. Li and L. Yu: Silicon, 2015, vol. 7, pp. 239-246.

L. Hu, Z. Wang, X. Gong, Z. Guo and H. Zhang: Sep. Purif. Technol., 2013, vol. 118, pp. 699-703.

S. Esfahani and M. Barati: Met. Mater. Int., 2011, vol. 17, pp. 823-829.

S. Esfahani and M. Barati: Met. Mater. Int., 2011, vol. 17, pp. 1009-1015.

A. M. Mitrašinović and T. A. Utigard: Chem. Phys. Lett., 2011, vol. 515, pp. 72-77.

A. M. Mitrašinović and T. A. Utigard: Silicon, 2009, vol. 1, pp. 239-248.

J. C. Anglézio, C. Servant and F. Dubrous: J. Mat. Res., 1990, vol. 5, pp. 1894-1899.

H. Lu, K. Wei, W. Ma, K. Xie, J. Wu and Y. Lei: Metal. Mat. Trans. B, 2017, vol. 48, pp. 2768-2780.

F. Margarido, M. O. Figueiredo, A. M. Queiroz and J. P. Martins: Ind. Eng. Chem. Res., 1997, vol. 36, pp. 5291-5295.

H. Lai, L. Huang, C. Lu, M. Fang, W. Ma, P. Xing, J. Li and X. Luo: Hydrometallurgy, 2015, vol. 156, pp. 173-181.

H. Lai, Z. Sheng, J. Li, P. Xing and X. Luo: Sep. Purif. Technol., 2017, vol. 191, pp. 257-269.

J. Li, B. Ban, Y. Li, X. Bai, T. Zhang and J. Chen: Silicon, 2017, vol. 9, pp. 77-83.

J. Li, H. Tang, Z. Guo and Y. Lin: ICMREE, Chengdu, China, 2014.

C.W. Bale, E. Bélisle, P. Chartrand, S. A. Decterov, G. Eriksson, A. E. Gheribi, K. Hack, I. H. Jung, Y. B. Kang, J. Melançon, A. D. Pelton, S. Petersen, C. Robelin, J. Sangster, P. Spencer and M. A.Van Ende: Calphad, 2016, vol. 55, pp. 1-19.

H. S. Kim, Y. Kobayashi and K. Nagai: J. MATER. RES., 2006, vol. 21, pp. 1399–1408.

F. Weitzer, J. C. Schuster, M. Naka, F. Stein and M. Palm: Intermetallics, 2008, vol. 16, pp. 273-282.

H. Erhart, H. J. Grabke and R. Möller: Archiv für das senhüttenwesen, 1983, vol. 54, pp. 285-289.

H. Ohtani, N. Hanaya, M. Hasebe, S. Teraoka and M. Abe: Calphad, 2006, vol. 30, pp. 147–158.

O. Toma, M. Dzevenko, A. Oliynyk, and Y. Lomnytska: Open Chem., 2013, vol. 11

D. Tao: Thermochim. Acta, 2000, vol. 363, pp. 105-113.

D. Tao: Acta Metall. Sin-Engl., 2001, vol. 14, pp. 241-247.

K. Liu, J. Wu, W. Ma, B. Yang and Y. Dai: J. Min. Metall. B, 2014, vol. 50, pp. 171-176.

T. Iida and R. I. L. Guthrie: The physical properties of liquid metal, Oxford Univ., Clarendon Press, Oxford, 1988, pp. 20-36.

R. R. Hultgren: Selected Values of the Thermodynamic Properties of Binary Alloy, American Society of Metals, Metals Park, OH, 1973, pp. 48-55.

B. Predel (2006) Landolt-Bornstein: Group IV: Physical Chemistry, vol. 12, Springer, Heidelberg, pp. 15-26.

IC Santos, AP Gonçalves, CS Santos, M Almeida, M Hafonso, and MJ Cruz (1990) Hydrometallurgy 23: 237-246

X. Ma, J. Zhang, T. Wang and T. Li: Rare Metals, 2009, vol. 28, pp. 221-225.

F. He, S. Zheng and C. Chen: Metal. Mater. Trans. B, 2012, vol. 43, pp. 1011-1018.

R. Zeng, Y. Wang, J. Zhang, J. Xu, H. Li, X. Chen and D. Xing: Advanced Materials Research, 2012, vol. 549, pp. 428-431.

Acknowledgments

We gratefully acknowledge that this study was supported by the National Natural Science Foundation of China (No.U1902219), the funding of the Yunnan Young and Middle-aged Academic and Technical Leader Reserve Talent Project (No. 2018HB009), and the Major Science and Technology Projects in Yunnan Province (No. 2019ZE007).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 27, 2020; accepted October 31, 2020.

Rights and permissions

About this article

Cite this article

Deng, X., Li, S., Wen, J. et al. Mechanism of Enhancing Phosphorus Removal from Metallurgical Grade Silicon by Si-Fe-Ti Phase Reconstruction. Metall Mater Trans B 52, 625–632 (2021). https://doi.org/10.1007/s11663-020-02028-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-02028-y