Abstract

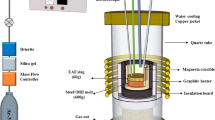

The effect of CaF2 addition on dephosphorization reaction between molten steel and electric arc furnace (EAF) slag using direct reduced iron (DRI) at 1823 K (1550 °C) was investigated. Basicity, the thermodynamic parameter affecting the removal capacity of phosphorus (i.e., phosphate capacity), decreased using DRI due to an increased SiO2 concentration in the slag. To minimize slag volume and maximize dephosphorization efficiency, the CaF2 was added to the slag. As CaF2 content increased (0 to 10 mass pct), dephosphorization efficiency also increased. Thermodynamic analysis in conjunction with slag structural studies using Raman spectroscopy were conducted to explain the complicated phenomena. The results exhibited that even 5 to 6 mass pct CaF2 can improve the dephosphorization efficiency when DRI is used as raw material in an EAF process.

Similar content being viewed by others

References

[1]R.D. Morales, A.N. Conejo and H.H. Rodriguez: Metall. Mater. Trans. B, 2002, vol. 33B, pp. 187-99.

[2]T. Harada and H. Tanaka: ISIJ Int., 2011, vol. 51, pp. 1301-07.

[3]M. Kirschen, K. Badr and H. Pfeifer: Energy, 2011, vol. 36, pp. 6146-55.

[4]A.A. Maneti, P. Duarte and J. Morales: Proc. AISTech 2016, 2016, pp. 64-70.

[5]F. Memoli: Proc. AISTech 2016, 2016, pp. 91-100.

[6]C. Yilmaz and T. Turek: J. Clean. Prod., 2017, vol. 164, pp. 1519-30.

[7]R.L. González, F.L. Acosta, M. Lowry, D. Kundrat, A. Wyatt, J. Kuntze and H. Fuchs: Proc. AISTech 2017, 2017, pp. 1035-41.

[8]P. Duarte and J. Martinez: Proc. AISTech 2017, 2017, pp. 815-24.

[9]P. Duarte, J. Morales, F. Memoli and A. Martinis: Proc. AISTech 2017, 2017, pp. 955-61.

[10]T.A. Bloom, D.R. Fosnacht and D.M. Haezebrouck: Iron & Steelmaker, 1990, vol. 17, pp. 35-41.

[11]R.J. Fruehan and C.P. Manning: Behavior of Phosphorus in DRI/HBI during Electric Furnace Steelmaking, AISI/DOE Technology Roadmap Program, Final Report, Oct. 5, 2001, pp. 1-200.

[12]J.H. Heo and J.H. Park: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 3381-89.

[13]K. Sadrnezhaad: Scientia Iranica, 1996, vol. 3, pp. 113-19.

[14]G. Li, T. Hamano and F.Tukihashi: ISIJ Int., 2005, vol. 45, pp.12-18.

[15]T. Hamano and F. Tukihashi: ISIJ Int., 2005, vol. 45, pp.159-65.

[16]C.M. Lee and R.J. Fruehan: Ironmaking & Steelmaking, 2005, vol. 32, pp. 503-08.

[17]G.J.W. Kor: Metall. Trans. B, 1977, vol. 8B, pp. 107-13.

[18]H. Suito, R. Inoue and M. Takada: Trans. ISIJ, 1981, vol. 21, pp. 250-59.

[19]H. Suito and R. Inoue: Trans. ISIJ, 1982, vol. 22, pp. 869-77.

[20]Y. Shirota, K. Katohgi, K. Klein, H.J. Engell and D. Janke: Trans ISIJ, 1985, vol. 25, pp. 1132-40.

[21]B.J. Monaghan, R.J. Pomfret and K.S. Coley: Metall. Mater. Trans. B, 1998, vol. 29B, pp. 111-18.

[22]W.H. Van Niekerk and R.J. Dippenaar: Metall. Mater. Trans. B, 1998, vol. 29B, pp. 147-53.

[23]J.H. Park, D.J. Min and H.S. Song: Metall. Mater. Trans. B, 2002, vol. 33B, pp. 723-29.

[24]J.H. Park and D.J. Min: J. Non-Cryst. Solids, 2004, vol. 337, pp. 150-56.

[25]K.Y. Ko and J.H. Park: ISIJ Int., 2013, vol. 53, pp. 958-65.

[26]T.S. Kim and J.H. Park: ISIJ Int., 2014, vol. 54, pp. 2031-38.

[27]J.H. Park, K.Y. Ko and T.S. Kim: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 741-48.

[28]T.S. Kim and J.H. Park: J. Am.Ceram. Soc., 2019, vol. 102, pp. 4943-55.

[29]D. Virgo, B.O. Mysen and I. Kushiro: Sience, 1980, vol. 208, pp. 1371-73.

B.O. Mysen and P. Richet: Glasses and Melts: Properties and Structure, Amsterdam, Boston, 2005, pp. 69-100.

[31]J.H. Park: ISIJ Int., 2012, vol. 52, pp. 1627-36.

[32]J.H. Park: ISIJ Int., 2012, vol. 52, pp. 2303-04.

[33]J.H. Park: J. Non-Cryst. Solids., 2012, vol. 358, pp. 3096-3102.

[34]J.H. Park: Met. Mater. Int., 2013, vol. 19, pp. 577-84.

[35]J.H. Park: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 938-47.

[36]T.S. Kim, S.J. Jeong and J.H. Park: Met. Mater. Int., 2019, https://doi.org/10.1007/s12540-019-00474-1.

[37]J.H. Park and D.J. Min: Steel Research Int., 2004, vol. 75, pp. 807-11.

[38]C. Wagner: Metall. Trans. B, 1975, vol. 6B, pp. 405-09.

[39]M. Yamamoto, K. Yamada, L.L. Meshkov and E. Kato: Tetsu-to-Hagane, 1980, vol. 66, pp. 2032-39.

T.A. Engh, C.J. Simensen and O. Wijk: Principles of Metal Refining, Oxford University Press, 1992.

M. Hino and K. Ito: Thermodynamic Data for Steelmaking, The 19th Committee in Steelmaking, The Japan Society for Promotion of Science (JSPS), Tohoku University Press, 2010, pp. 259-64.

N. Sano: Advanced Physical Chemistry for Process Metallurgy, Academic Press, 1997, p. 45.

[43]J.H. Park and D.J. Min: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 689-94.

[44]J.H. Park, G.H. Park and Y.E. Lee: ISIJ Int., 2010, vol. 50, pp. 1078-83.

[45]K.Y. Ko and J.H. Park: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 1224-30.

[46]S.H. Lee, S.M. Moon, D.J. Min and J.H. Park: Metall. Mater. Trans. B, 2002, vol. 33B, pp. 55-59.

www.factsage.com (accessed on 1st April 2020).

[48]S. Hara, T. Tokonami and K. Ogino: Tetsu-to-Hagane, 1992, vol. 78, pp. 557-63.

[49]M.K. Cho, J.H. Park and D.J. Min: ISIJ Int., 2010, vol. 50, pp. 324-26.

[50]C.H.P. Lupis: Chemical Thermodynamics of Materials, North-Holland, New York, 1983, pp. 155-58.

[51]W. Fix, H. Heymann and R. Heinke: J. Am. Ceram. Soc., 1969, vol. 52, pp. 346-47.

[52]H. Suito and R. Inoue: ISIJ Int., 2006, vol. 46, pp. 180-87.

[53]F. Pahlevani, S. Kitamura, H. Shibata and N. Maruoka: ISIJ Int., 2010, vol. 50, pp. 822-29.

[54]J.H. Shin and J.H. Park: ISIJ Int., 2013, vol. 53, pp. 2266-68.

[55]M. Muraki, H. Fukushima and N. Sano: Trans. ISIJ, 1985, vol. 25, pp. 1025-30.

[56]I. Iwasaki, E.F. Wu and T. Fujita: Min. Process. Extract. Metall. Rev., 1993, vol. 12, pp. 19-36.

[57]G.H. Park, Y.B. Kang and J.H. Park: ISIJ Int., 2011, vol. 51, pp. 1375-82.

[58]Y.B. Kang and J.H. Park: Metall. Mater. Trans. B, 2011, vol. 42B, 1211-17.

[59]J.H. Park and G.H. Park: ISIJ Int., 2012, vol. 52, pp. 764-69.

[60]J.H. Park: Steel Res. Int., 2013, vol. 84, pp. 664-69.

[61]S.J. Jeong, T.S. Kim and J.H. Park: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 545-53.

[62]J.H. Park, J.G. Park, D.J. Min, Y.E. Lee and Y.B. Kang: J. Eur. Ceram. Soc., 2010, vol. 30, pp. 3181-86.

[63]J.S. Han, J.H. Heo and J.H. Park: Ceram. Int., 2019, vol. 45, pp. 10481-91.

T.S. Kim and J.H. Park: J. Non-Cryst. Solids, 2020, in press.

[65]J.H. Park and D.J. Min: ISIJ Int., 2007, vol. 47, pp. 1368-69.

[66]J.D. Frantz and B.O. Mysen: Chem Geol., 1995, vol. 121, pp. 155-76.

[67]Y.Q. Wu, G.C. Jiang, J.L. You, H.Y. Hou, H. Chen and K.D. Xu: J. Chem. Phys., 2004, vol. 121, pp. 7883-95.

Acknowledgments

This work was supported by the Competency Development Program for Industry Specialists from the Korea Institute for Advancement of Technology (KIAT, Grant Number P0002019) and the Korea Institute of Energy Technology Evaluation and Planning (KETEP, Grant Number 20172010106310), funded by the Ministry of Trade, Industry & Energy (MOTIE), Korea.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 22, 2020.

Rights and permissions

About this article

Cite this article

Oh, M.K., Kim, T.S. & Park, J.H. Effect of CaF2 on Phosphorus Refining from Molten Steel by Electric Arc Furnace Slag using Direct Reduced Iron (DRI) as a Raw Material. Metall Mater Trans B 51, 3028–3038 (2020). https://doi.org/10.1007/s11663-020-01957-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01957-y