Abstract

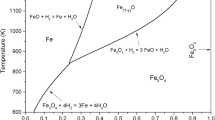

A sample of limonitic nickel ore was characterized by XRD, SEM-EDS, and ICP-OES techniques. The Rietveld refinement method showed that the main mineral constituent of this sample is goethite (55.8 pct). Thermal analysis experiments were performed and the determination of the goethite content in the sample could be confirmed by the mass loss associated to the dehydroxylation of this mineral at temperature of ≈ 150 °C. After thermal decomposition, the sample was reduced in a rotary kiln using hydrogen and subsequent characterization showed that for low temperatures (400 °C ≤ T < 550 °C) the main chemical reaction is the reduction of hematite to magnetite. At high temperatures (500 °C ≤ T < 800 °C), metallic iron could be identified in the solid product of the reaction by XRD technique and reduction of hematite to metallic iron was the main chemical reaction identified at this temperature. In addition to metallic iron, tetrataenite was identified and quantified in the reduced sample at high temperature (T > 600 °C) and the results suggest that most of the nickel is in this mineral phase. The shrinking core model was used for the kinetic studies of the reduction process and for the reduction of hematite to magnetite at low temperature (T ≤ 550 °C). The slow step was diffusion of reagent (H2) or product (H2O) through the reduced solid product layer on the particle surface, the apparent activation energy calculated for the reaction was 46.2 kJ. For the reduction of hematite to metallic iron at high temperature (T ≥ 550 °C), the slow step was the reaction of hydrogen with hematite at the reaction surface of the particle, and the apparent activation energy achieved by the chemical reaction was 29.5 kJ.

Similar content being viewed by others

References

[1] A. Oxley, M.E. Smith, O. Caceres: Minerals Engineering, 2016, vol. 88, pp. 53-60.

H.T.B.M. Petrus, A.D.P. Putera, I.P. EdiSugiarto, I.W. Warmada, F. Nurjaman, W. Astuti, A.T. Mursito: Miner. Eng., 2019, vol. 132, pp. 126-133.

[3] D. Zhu, L. Pan, Z. Guo, J. Pan, F. Zhang: Advanced Powder Technology, 2019, vol. 30, pp. 451-460.

[4] J. Yang, G. Zhang, O. Ostrovski, S. Jahanshahi: Minerals Engineering, 2019, vol 131, pp. 79-89.

[5] A. Garces-Granda, G.T. Lapidus, O.J. Restrepo-Baena: Minerals Engineering, 2018, vol. 120, pp. 127-131.

[6] Ş. Kaya, Y.A. Topkaya: Minerals Engineering, 2011, vol. 24, pp. 1188-1197.

[7] C.A. Pickels, W. Anthony: Minerals Engineering, 2018, vol. 120, pp. 47-59.

[8] A. Oxley, N. Barcza: Minerals Engineering, 2013, vol. 54, pp. 2-13.

[9] A.R. Burkin: Extractive metallurgy of nickel, John Wiley & Sons, New York, 1987.

F. Crundwell, M. Moats, V. Ramachandran, T. Robinson, W.G. Davenport: Extractive Metallurgy of Nickel, Cobalt and Platinum-Group Metals, 1st edo. Elsevier, Amsterdam, 2011.

[11] D.M. B. I. Whittington: Mineral Processing and Extractive Metallurgy Review, 2000, vol. 21, pp. 527-600.

A.B.D.P. PratimaMeshram: Miner. Process. Extract. Metall. Rev., 2019, vol. 40, pp. 157-193.

[13] G.M. Mudd: Ore Geology Reviews, 2010, vol. 38, pp. 9-26.

[14] A. Garces-Granda, G.T. Lapidus, O.J. Restrepo-Baena: Minerals Processing and Extractive Metallurgy, 2018, vol. 120, pp. 127-131.

[15] R. Elliott, C.A. Pickles, J. Peacey: Minerals Engineering, 2017, vol. 100, pp. 166-176.

[16] C.A. Pickles, J. Forster, R. Elliott: Minerals Engineering, 2014, vol. 65, pp. 33-40.

[17] D. Yu, M. Zhu, T.A. Utigard, M. Barati: Minerals Engineering, 2013, vol. 54, pp. 32-38.

[18] J. Yang, G. Zhang, O. Ostrovski, S. Jahanshahi: Minerals Engineering, 2013, vol. 54, pp. 110-115.

[19] M. Rao, G. Li, T. Jiang, J. Luo, Y. Zhang, X. Fan: The Minerals, Metals & Materials Society, 2013, vol. 65, pp. 1573-1583.

[20] Y.-j. Li, Y.-s. Sun, Y.-x. Han, P. Gao: Transactions of Nonferrous Metals Society of China, 2013, vol. 23, pp. 3428-3433.

[21] B. Li, Y.G. Wei, H. Wang: Minerals Processing and Extractive Metallurgy, 2013, vol. 122, pp. 249-257.

[22] D.Q. Zhu, Y. Cui, K. Vining, S. Hapugoda, J. Douglas, J. Pan, G.L. Zheng: International Journal of Mineral Processing, 2012, vol. 106–109, pp. 1-7.

[23] M. Samouhos, M. Taxiarchou, R. Hutcheon, E. Devlin: Minerals Engineering, 2012, vol. 34, pp. 19-29.

[24] A. Bunjaku, M. Kekkonen, P. Taskinen: Minerals Processing and Extractive Metallurgy, 2012, vol. 121, pp. 16-22.

[25] J. Kim, G. Dodbiba, H. Tanno, K. Okaya, S. Matsuo, T. Fujita: Minerals Engineering, 2010, vol. 23, pp. 282-288.

[26] J. Li, X. Li, Q. Hu, Z. Wang, Y. Zhou, J. Zheng, W. Liu, L. Li: Hydrometallurgy, 2009, vol. 99, pp. 84-88.

[27] F. O’Connor, W.H. Cheung, M. Valix: International Journal of Mineral Processing, 2006, vol. 80, pp. 88-99.

[28] T.A. Utigard, M. Wu, G. Plascencia, T. Marin: Chemical Engineering Science, 2005, vol. 60, pp. 2061-2068.

[29] S.K. Sharma, F.J. Vastola, P.L. Walker Jr: Carbon, 1996, vol. 34, pp. 1407-1412.

K. Okamoto, Y. Ueda, and F. Noguchi: On the Mechanism of Nickel Segregation from Garnierite Ore, Kyushu Institute of Technology Academic Repository, 1970, pp. 23–40. https://core.ac.uk/download/pdf/147423683.pdf. Accessed 10 Apr 2020.

K. Okamoto, Y. Ueda, and F. Noguchi: Extraction of Nickel from Garnierite Ore by the Segregation-Magnetic Separation Process, Kyushu Institute of Technology Academic Repository, 1970, pp. 41–61. https://kyutech.repo.nii.ac.jp/?action=pages_view_mainactive_action=repository_view_main_item_detailitem_id=1846item_no=1page_id=13block_id=21. Accessed 10 Apr 2020.

S.L. JieLu, J Shangguan, W Du, F Pan, S Yang: Miner. Eng., 2013, vol. 49, pp. 154-164.

[33] C. Sheng-li, G. Xue-yi, S. Wen-tang, L. Dong: Journal of Central South University Technology, 2010, vol. 17, pp. 765-769.

[34] S. Zhou, Y. Wei, B. Li, H. Wang, B. Ma, C. Wang: Scientific Reports, 2016, vol. 6, pp. 1-11.

[35] M. Jiang, T. Sun, Z. Liu, J. Kou, N. Liu, S. Zhang: International Journal of Mineral Processing, 2013, vol. 123, pp. 32-38.

[36] B. Ma, C. Wang, W. Yang, F. Yin, Y. Chen: Minerals Engineering, 2013, vol. 50–51, pp. 106-113.

V.A. Oliveira, C.G.D. Santos, E.A. Brocchi: Metall. Mater. Trans. B, 2019 vol. 50B, pp. 1309-1321.

[38] M. Landers, R.J. Gilkes: Applied Clay Science, 2007, vol. 35, pp. 162-172.

[39] C.A. Pickles, R. Elliott: Minerals Processing and Extractive Metallurgy, 2015, vol. 00, pp. 1-9.

DiplKrist, G. S. (1972) Kristall und Technik, vol. 7, pp. 235-46.

[41] E. Zepeda-Alarcon, H. Nakote, A.F. Gualtieri, G. King: Journal of Applied Crystallography, 2014, vol. 47, pp. 1983-1991.

V.G. Tsirel'Son, M.Y. Antipin, V.A. Strel’Tsov, R.P. Ozerov, Y.T. Struchkov: Soviet Phys. Doklady, 1988, vol. 33, pp. 1137–1141.

S.M. E., D.C. Kim: Z Metallkunde, 1969, vol. 69, pp. 272-77.

[44] M.E. Fleet: Journal of Solid State Chemistry, 1986, vol. 62, pp. 75-82.

H. D’amour, W. Denner, H. Schulz: Acta Crystallogr. Sect. B, 1979, vol. B35, pp. 550–55. https://doi.org/10.1107/S056774087900412X.

T. Tagai, H. Takeda, T. Fukuda: Z. fur Kristallogr., 1995, vol. 210 (1), pp. 14–18. https://doi.org/10.1524/zkri.1995.210.1.14.

[47] A. Yamamoto: Acta Crystallographica Section B: Structural Crystallography and Crystal Chemistry, 1982, vol. 38, pp. 1451-1456.

[48] K. Kihara, G. Donnay: The Canadian Mineralogist, 1985, vol. 23, pp. 647-654.

A.D.D.W.G.B.R.C. Osborne: The Past and the Future of Nickel Laterites. PDAC 2004 International Convention, Trade Show & Investors Exchange Toronto, 2004, pp. 1–27.

[50] B.B.K. Y. V. Swamy, J. K. Mohanty: Hydrometallurgy, 2003, vol. 69, pp. 89-98.

[51] H. Liu, T. Chen, X. Zou, C. Qing, R.L. Frost: Thermochimica Acta, 2013, vol. 568, pp. 115-121.

[52] B.Z. Dlugogorski, R.D. Balucan: Renewable and Sustainable Energy Reviews, 2014, vol. 31, pp. 353-367.

V.D. EnioLima, P F. P. Fichtner, P H. P. Domingues: Solid State Commun., 2003, vol. 128, pp. 345-350.

[54] D.B.W. C. W. Yang, J. I. Goldstein: Journal of Phase Equilibria, 1996, vol. 17, pp. 522-531.

[55] B. Janković, B. Adnađević, S. Mentus: Chemical Engineering Science, 63 (2008) 567-575.

[56] B. Li, Y.-g. Wei, H. Wang: Transactions of Nonferrous Metals Society of China, 2014, vol. 24, pp. 3710-3715.

[57] M.H. Jeong, D.H. Lee, J.W. Bae: International Journal of Hydrogen Energy, 2015, vol. 40, pp. 2613-2620.

[58] H.-Y. Lin, Y.-W. Chen, C. Li: Thermochimica Acta, 2003, vol. 400, pp. 61-67.

[59] A. Pineau, Ş. Kaya, I. Gaballah: Thermochimica Acta, 2007, vol. 456, pp. 75-88.

[60] A. Pineau, N. Kanari, I. Gaballah: Thermochimica Acta, 2006, vol. 447, pp. 89-100.

E.F. ParvizPourghahramani: Thermochim. Acta, 2007, vol. 454, pp. 69-77.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 17, 2019.

Rights and permissions

About this article

Cite this article

de Alvarenga Oliveira, V., de Jesus Taveira Lana, R., da Silva Coelho, H.C. et al. Kinetic Studies of the Reduction of Limonitic Nickel Ore by Hydrogen. Metall Mater Trans B 51, 1418–1431 (2020). https://doi.org/10.1007/s11663-020-01841-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01841-9