Abstract

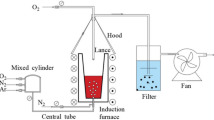

Bottom-blowing O2-CaO steelmaking technology has numerous advantages such as low iron and steel consumptions, low dust emissions, and molten steel cleanliness. Responsive to a weak stirring and high iron oxide slag in a 120-ton conventional “combined blowing” converter in a factory, a cold model of bottom-blowing O2-CaO was designed. Bottom-blowing and top-blowing parameters on the mixing effect of bottom-blowing O2-CaO converter were studied. Two symmetrical points on 0.4R trunnion connection of the bottom-blowing converter were sought as the optimum hole location. The total flow rate of bottom–blowing and top-blowing was 8.2 and 75 Nm3/h, respectively. The optimum top-blowing position was 400 mm and the optimum solid–gas ratio was found to be 9.0. The optimum scheme under laboratory conditions was converted and applied to a 120-ton bottom-blown O2-CaO converter; subsequently, hundred industrial tests were performed. The stirring strength of the molten bath was enhanced remarkably and the metallurgical effect was improved remarkably. Carbon and oxygen product of the end-point molten steel was reduced by 5.87 × 10−4 while the iron oxide content in the final slag was reduced by 1.99 pct. This laid a foundation for industrial applications of the bottom-blown O2-CaO converter steelmaking technology.

Similar content being viewed by others

References

Holappa L: Mineral Processing and Extractive Metallurgy, 2019, 128(1-2): 3-16.

Zhou Wang, Feiming Xie, Bin Wang, et al: Steel Research International, 2014, 85(4):599-606.

Kaike Cai: Iron & Steel, 2009, 44(5): 27-31.

SC Koria: Canadian Metallurgical Quarterly, 1992, 31(2): 105-112.

AK Shukla, B Deo, S Millman, et al: Steel Research International, 2010, 81(11): 940-948.

W Xiong, G Li, Z Chen, et al: Chinese Journal of Process Engineering, 2009, 9(S1): 369–73.

Wei Wu, Zongshu Zou, Zhenhe Guo, et al: Journal of Iron & Steel Research, 2004, 16(1): 21-24.

Savard G, Lee R. Campbell M R: JOM, 1960, 12(7): 566-569.

Kai Dong, Rong Zhu, Wenjuan Liu: Advanced Materials Research, 2012, 361-363: 639-643.

A.L. Aleksashin, I. Schnaltzger, G. Hollias: Metallurgist, 2007, 51(1-2): 60-65.

B. Tang, X. Wang, Z. Zou, et al: Canadian Metallurgical Quarterly, 2016, 55(1): 124-130.

H. Ono, T. Masui, H. Mori: Trans. Iron Steel Inst. Jpn, 1985, 25(2): 133-141.

Xiaobin Zhou, Mikael Ersson, Liangcai Zhong, et al: Metallurgical & Materials Transactions B, 2016, 47(1): 434-445.

BL Farrand, T Wyatt: Iron and Steelmaker, 1990, 17(11): 52-7.

H. Gou, G.A. Irons, W.K. Lu: EG and G Idaho, Inc., Idaho Falls, ID (United States); McMaster Univ., Hamilton, ON (Canada). Dept. of Materials Science and Engineering, 1992.

H. Gou, G.A. Irons, W.K. Lu: Metallurgical Transactions B, 1993, 24(1): 179-188.

B.L Farrand, J.E. Wood, and F.J. Goetz. Dofasco, Inc., Hamilton, ON, Canada, 1992, pp. 173–79. https://www.osti.gov/biblio/10146986.

D.S. Liao, Sun S, Waterfall S, et al: Proc. 6th Int. Cong. Sci. Technol. Steelmaking, Beijing, China, 2015, 12–14.

Lihua Guan, Shikai Qi, Kaiwen Deng: Iron and Steel, 1982, 17(8):14-20.

Chenglin Zhao, Jianwei Li, Zongshu Zou, et al: China Metallurgy, 2006, 16(8): 1-1.

Dong Xu, Daqiang Cang, Lixue Qin, et al: Journal of University of Science and Technology Beijing, 2012, 34(9): 1065-1071.

Y Li: Gangtie, 1980, 3: 1–9.

N.B. Ballal, A.Ghosh: Metallurgical and Materials Transactions B, 1981, 12(3):525-534.

Dongxing Wang, Yan Liu, Zimu Zhang, et al: AIP Conference Proceedings. American Institute of Physics, 2013, 1542(1): 1304-1307.

G. Wen, P. Tang, and G. Yan: J. Chongqing Univ., 1991, vol. 6, pp. 31–37.

Acknowledgments

This work was financially supported by the National Natural Science 240 Foundation of China (Grant Nos. 51574021 and 51474024).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 23, 2019.

Rights and permissions

About this article

Cite this article

Li, W., Zhu, R., Dong, K. et al. Physical Simulation and Industrial Testing of Bottom-Blown O2-CaO Converter for Steelmaking Process. Metall Mater Trans B 51, 1060–1069 (2020). https://doi.org/10.1007/s11663-020-01823-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01823-x