Abstract

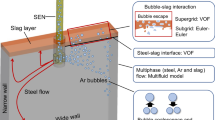

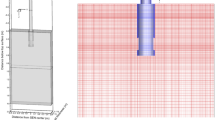

The multiphase flow, heat transfer, and initial solidification behaviors in a 230 × 1300 mm2 continuous casting slab mold under different argon blowing rates were investigated by a multi-physical model. Water model experiments were conducted to validate the numerical models. The results showed that the simulated steel/slag level fluctuation and argon bubble trajectories were basically consistent with the experimental results. Only the bubbles less than 1 mm were dragged to the narrow face, while larger bubbles were more likely to escape from the free surface. When the argon blowing rate increased from 0 to 15 L/min, the impact depth of the molten steel decreased. The velocity and level fluctuation range near the submerged entry nozzle (SEN) first decreased and then increased. Moreover, the largest level fluctuation decreased to 4 mm when the argon blowing rate was 5 L/min. Meanwhile, the solidified shell thickness at narrow face of mold outlet decreased from 12.5 to 6.7 mm and became too thin to easily break out when argon blowing rate reached over 10 L/min. By comprehensively considering the multiphase flow, heat transfer, and solidification behavior in the mold, the proper argon blowing rate range should be 5 L/min, by which the disqualification rate of inclusion at strip edge can be decreased from 4.28 to 1.75 pct.

Similar content being viewed by others

References

Q. Fang, H. Ni, B. Wang, H. Zhang, and F. Ye: Metals, 2017, vol. 7, Article No. 72.

B.G. Thomas: Steel Res. Int., 2018, vol. 89, Article No. 1700312.

3 J. Yang, Z. Cai and M. Zhu: ISIJ Int., 2018, vol. 58, pp. 299-308.

T. Zhang, J. Yang, and P. Jiang: Metals, 2019, vol. 9, Article No. 36.

W. Zhang, S. Luo, Y. Chen, W. Wang, and M. Zhu: Metals, 2019, vol. 9, Article No. 66.

6 B. Yang, J. Li, L.W. Zhang, Y. Zhang, Y. Cui and C.J. Xu: Tehnički vjesnik, 2019, vol. 26, pp. 566-570.

7 S.M. Cho, B.G. Thomas and S.H. Kim: Metall. Mater. Trans. B, 2019, vol. 50, pp. 52-76.

L. Jin, J. Cheng, and H. Shen: Metall. Res. Technol., 2017, vol. 114, Article No. 103.

9 Z. Liu, Z. Sun and B. Li: Metall. Mater. Trans. B,, 2017, vol. 48(2),pp. 1248-1267.

S. Li, P. Lan, H. Tang, Z. Tie, and J. Zhang: Steel Res. Int., 2018, vol. 89, Article No. 1800071.

M. Long, H. Chen, D. Chen, S. Yu, B. Liang, and H. Duan: Metals, 2018, vol. 8, Article No. 182.

12 T. Zhang, Z. Luo, H. Zhou, B. Ni and Z. Zou: ISIJ Int., 2016, vol. 56, pp. 116-125.

13 X. Li, B. Li, Z. Liu, R. Niu, Y. Liu, C. Zhao, C. Huang, H. Qiao and T. Yuan: Metals, 2019, vol. 9, 7.

Z. Liu, B. Li, A. Vakhrushev, M. Wu, and A. Ludwig: Steel Res. Int., 2019, vol. 90, Article No. 1800117.

W. Chen, Y. Ren, and L. Zhang: Steel Res. Int., 2019, vol. 90, Article No. 1800287.

16 Z. Liu, B. Li, F. Qi and S. C. P. Cheung: Powder Technology, 2017, vol. 319, pp. 139-147.

17 H. Zhang, Q. Fang, T. Xiao, H. Ni and C. Liu: ISIJ Int., 2019, vol. 59, pp. 86-92.

18 W. Chen, Y. Ren, L. Zhang and P.R. Scheller: JOM, 2019, vol. 71, pp. 1158-1168.

19 S. Zheng and M. Zhu: Int. J. Min. Met. Mater., 2010, vol. 17, pp. 704-708.

20 Z. Liu, B. Li and M. Jiang: Metall. Mater. Trans. B, 2014, vol. 45, pp. 675-697.

21 Z. Liu, F. Qi, B. Li, and S. C. P. Cheung: International Journal of Multiphase Flow, 2016, vol. 79, pp.190–201.

22 C. Cheng, H. Lu, Y. Li, X. Qing and Y. Jin: ISIJ Int., 2019, vol. 59, pp. 1266-1275.

23 B. Ren, D. Chen, H. Wang, M. Long and Z. Han: Ironmak. Steelmak., 2015, vol. 42, pp. 401-408.

ANSYS Fluent 15.0 Theory Guide, Southpointe, 2013.

25 H. Zhang, C. Liu, Q. Fang, Y. Wang, H. Ni and C. Liu: Ironmak. Steelmak., 2019, https://doi.org/10.1080/03019233.2019.1665909.

26 Z. Liu, L. Li, B. Li and M. Jiang: JOM, 2014, vol. 66, pp. 1184-1196.

27 H. Zhang, Q. Fang, R. Luo, C. Liu and H. Ni: Metall. Mater. Trans. B, 2019, vol. 50, pp. 1461-1475.

28 J. Savage and W.H. Pritchard: Journal of the Iron and Steel Institute, 1954, vol. 178, pp. 269-277.

29 R..D. Morales, A.G. López and I.M. Olivares: ISIJ Int., 1990, vol. 30, pp. 48-57.

Acknowledgments

The authors would like to express their gratitude for the financial support provided by the National Natural Science Foundation of China (51774217) and (51604201).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 28, 2019.

Rights and permissions

About this article

Cite this article

Wang, Y., Fang, Q., Zhang, H. et al. Effect of Argon Blowing Rate on Multiphase Flow and Initial Solidification in a Slab Mold. Metall Mater Trans B 51, 1088–1100 (2020). https://doi.org/10.1007/s11663-020-01804-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01804-0