Abstract

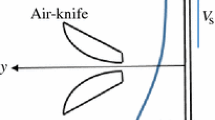

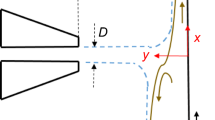

Gas-jet wiping is a widely employed production technology for controlling the final zinc coating thickness on a moving substrate during continuous hot-dip galvanizing. This paper presents an experimental investigation and numerical analysis of a prototype multi-slot air knife, which offers an increase in wiping efficiency relative to the traditional single-slot jet geometry in the continuous galvanizing process. The applicability of the analytical coating weight model of Elsaadawy et al. (Metall Mater Trans B, 38:413-424, 2007) to predict the final coating weight was determined for the multi-slot geometry, where particular focus was devoted to the effect of geometric parameters. Experimental measurements under a variety of knife geometry and process conditions agreed with the coating weight predictions of the analytical model. It was also shown that the air-knife geometric parameters had a significant effect on the pressure profile and shear stress distribution applied by the air knives to the moving substrate. It was determined that the final coating thickness was significantly affected by the auxiliary jet width, Da, where lighter coating weights at higher strip velocities (up to 5.4 pct at Vs = 1.5 m/s) could be achieved by using the multi-slot air-knives prototype vs. the conventional single-slot configuration.

Similar content being viewed by others

Abbreviations

- c :

-

Speed of sound (m/s)

- R :

-

Universal gas constant (J/mol K)

- D :

-

Main jet width (m)

- Re :

-

Jet Reynolds number \( \left( {\text{Re} = \frac{\rho uD}{\mu }} \right) \)

- D a :

-

Auxiliary jet width (m)

- S :

-

Non-dimensional shear stress

- g :

-

Gravitational acceleration (m/s2)

- s :

-

Auxiliary jet offset distance (m)

- G :

-

Non-dimensional pressure gradient

- T :

-

Temperature (K)

- h f :

-

Final film thickness (m)

- U :

-

Fluid velocity (m/s)

- h :

-

Local film thickness (m)

- V s :

-

Strip velocity (m/s)

- H :

-

Non-dimensional film thickness

- Z :

-

Main jet exit-to-wall distance (m)

- L :

-

Computational domain length (m)

- μ :

-

Fluid dynamic viscosity (kg/m s)

- L s :

-

Strip width (m)

- μ t :

-

Turbulent viscosity (kg/m s)

- \( \dot{m} \) :

-

Mass flow rate of removed oil (kg/s)

- ρ cl :

-

Coating liquid density (kg/m3)

- P :

-

Static pressure (Pa)

- γ :

-

Ratio of specific heats of air

- P s :

-

Nozzle static pressure (Pa)

- τ :

-

Shear stress (Pa)

- P ∞ :

-

Ambient pressure (Pa)

- ρ :

-

Density of gas (kg/m3)

- q :

-

Withdrawal flux (m2/s)

- ρ cl :

-

Density of coating liquid (kg/m3)

- Q :

-

Non-dimensional withdrawal flux

References

Elsaadawy EA, Hanumanth GS, Balthazaar AKS, McDermid JR, Hrymak AN, Forbes JF (2007) Metall Mater Trans B 38:413–24

2 A.R. Marder: Prog. Mater. Sci., 2000, vol. 45, pp. 191–271.

3 J.A. Thornton and H.F. Graff: Metall. Trans. B, 1976, vol. 7, pp. 607–18.

4 C.H. Ellen and C. V. Tu: J. Fluids Eng., 1983, vol. 106, pp. 399–404.

M. Dubois: Galvatech 2011 Conf. Proc.: HDG Process Technol., Genova, 2011, pp. 1847–59.

6 E.O. Tuck: Phys. Fluids, 1983, vol. 26, pp. 2352–8.

H. Yoneda: Master of Applied Science Thesis, University of Minnesota, USA, 1993.

8 C. V Tu and D.H. Wood: Exp. Therm. Fluid Sci., 1996, vol. 13, pp. 364–73.

Tuck EO, Vanden Broeck J-M (1984) AIChE J 30:808–11

Hrymak AN, Elsaadawy EA, Hanumanth G, McDermid JR, Goodwin FE (2005) AISTech Proc II:393–401

A. Gosset, P. Rambaud, L. Castellano, M. Dubois, and J.M. Buchlin: 6th Eur. Coat. Symp., Bradford, UK, 2005.

13 J.-R. Park: Ironnmaking Steelmak., 2001, vol. 28, pp. 53–7.

14 D. Arthurs and S. Ziada: J. Can. Acoust. Assoc., 2007, vol. 35, pp. 28–9.

15 K. Myrillas, A. Gosset, P. Rambaud, M. Anderhuber, J.M. Mataigne, and J.M. Buchlin: Chem. Eng. Process. Process Intensif., 2011, vol. 50, pp. 466–70.

G.Y. Kim, H.D. Park, D.E. Lee, and W.C. Chung: US 2010/0031879 A1: 2008.

P. Tamadonfar, J.R. McDermid, A.N. Hrymak, and F.E. Goodwin: AISTech—Iron Steel Technol. Conf. Proc., Pittsburgh, 2010, pp. 517–25.

P. Tamadonfar, J.R. McDermid, A.N. Hrymak, and F.E. Goodwin: 8th Int. Conf. Zinc Zinc Alloy Coat. Steel Sheet (GalvaTech 2011), Genova, Italy, 2011.

S. Alibeigi, J.R. McDermid, S. Ziada, and F.E. Goodwin: Galvatech 2013 9th Int. Conf. Zinc Zinc Alloy Coat. Steel Sheet 2nd Asia-Pac. Galvaniz. Conf., Beijing, 2013, pp. 437–40.

D. Finnerty, J. McDermid, F. Goodwin, and S. Ziada: Galvatech 2017 11th Int. Conf. Zinc Zinc Alloy Coat. Steel Sheet, Tokyo, 2017, pp. 307–13.

J.R. McDermid, D. Finnerty, S. Ziada, and F.E. Goodwin: 109th Meet. Galvaniz. Assoc., Troy, MI, 2017.

22 D. Arthurs and S. Ziada: J. Fluids Struct., 2012, vol. 34, pp. 236–58.

Yahyaee Soufiani A, McDermid JR, Hrymak AN, Goodwin FE (2017) J Coat Technol Res 14:1015–28

A. Ritcey, J.R. McDermid, and S. Ziada: ICFMFA 2015: 17th Int. Conf. Fluid Mech. Flow Anal., 2015.

S. Alibeigi: Master of Applied Science Thesis, McMaster University, Canada, 2013.

26 F. M.White: Fluid Mechanics, fourth ed., McGraw-Hill, Boston, 2003, 866.

27 H.W. Coleman and W.G. Steele: Experimentation and Uncertainity Analysis for Engineers, Second ed., John Wiley & Sons, Inc., New York, 1999, 271.

Acknowledgments

The authors gratefully acknowledge the financial contributions of the International Zinc Association Galvanized Autobody Partnership (IZA-GAP) Members and the Natural Sciences and Engineering Research Council of Canada (NSERC, Grant CRDPJ 446105-2012) to the success of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 4, 2019.

Rights and permissions

About this article

Cite this article

Yahyaee Soufiani, A., McDermid, J.R., Hrymak, A.N. et al. Experimental and Numerical Study of Coating Thickness Using Multi-slot Air Knives. Metall Mater Trans B 50, 2523–2535 (2019). https://doi.org/10.1007/s11663-019-01666-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01666-1