Abstract

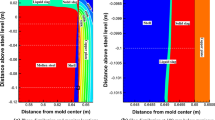

In the current study, the two-dimensional mold model was applied to investigate the influence of different casting parameters on the initial solidification at the meniscus of the continuous casting mold. The profile of the meniscus and the slag rim, and the heat flux on the hot face of the copper plate, were compared with different locations of the mold and different casting parameters. The depth of the oscillation marks and solidified meniscus through simulation was measured with different casting parameters. With the mold oscillating downward from the peak to the valley, the maximum heat flux on the hot face of the copper plate near the meniscus increased from 4.3 to 5.5 MW/m2, the thickness of the slag rim decreased from 4.7 to 4.2 mm, and the height of the curved meniscus also decreased. With the increase of casting speed from 1.2 to 1.45 m/min, the maximum speed of the upper backflow increased from 0.6 to 0.8 m/s, and the lowest location of the meniscus at approximately 310 mm from the copper plate decreased from 22 to 12 mm below the meniscus near the nozzle, where the slag entrapment easily occurred. With the increase of the casting speed, casting superheat, and oscillation frequency, and the decrease of the water flow rate in the mold and oscillation amplitude, the thickness of the slag rim decreased. With the increase of casting speed and superheat, and the decrease of the water flow rate in the mold, oscillation frequency, and oscillation amplitude, the depth of the solidified meniscus decreased. The regression equation was fitted to estimate the depth of hooks at the subsurface of slabs.

Similar content being viewed by others

References

E. Takeuchi: Ph.D. Thesis, UBC, 1984.

C. Ojeda, J. Sengupta, B.G. Thomas, J. Barco, and J.L. Arana: AISTech 2006, 2006, vol. 1, pp. 1017–28.

B.G. Thomas: Steel Res. Int., 2018, vol. 89, pp. 1700312.

K. Mills, P. Ramirez-Lopez, and P. Lee: High Temp. Mater. Processes, 2012, vol. 31, pp. 221–29.

X.B. Zhang, W. Chen, and L.F. Zhang: China Foundry, 2017, vol. 14, pp. 416–20.

X. Zhang, W. Chen, P.R. Scheller, Y. Ren, and L. Zhang: JOM, 2018, pp.

W. Wang, L. Zhou, and K. Gu: Met. Mater. Int., 2010, vol. 16, pp. 913–20.

H. Zhang and W. Wang: Metall. Mater. Trans. B, 2017, vol. 48, pp. 779–93.

P.E. Ramirez Lopez, P.N. Jalali, P.G. Jönsson, and K.C. Mills: ISIJ Int., 2018, vol. 58 (2), pp. 201–10.

P.E. Ramirez-Lopez, P.D. Lee, K.C. Mills, and B. Santillana: ISIJ Int., 2010, vol. 50, pp. 1797–1804.

E. Takeuchi and J. Brimacombe: Metall. Trans. B, 1984, vol. 15, pp. 493–509.

P.E.R. Lopez, K.C. Mills, P.D. Lee, and B. Santillana: Metall. Mater. Trans. B, 2012, vol. 43, pp. 109–22.

J. Sengupta, B.G. Thomas, H.-J. Shin, G.-G. Lee, and S.-H. Kim: Metall. Mater. Trans. A, 2006, vol. 37, pp. 1597–1611.

E. Takeuchi and J. Brimacombe: Metall. Mater. Trans. B, 1985, vol. 16, pp. 605–25.

S. Harada, S. Tanaka, H. Misumi, S. Mizoguchi, and H. Horiguchi: ISIJ Int., 1990, vol. 30, pp. 310–16.

J. Sengupta, H.-J. Shin, B. Thomas, and S.-H. Kim: Acta Mater., 2006, vol. 54, pp. 1165-73.

P.D. Lee, P.E. Ramirezlopez, K.C. Mills, and B. Santillana: Ironmak. Steelmak., 2012, pp. 244–53.

K.C. Mills, P. Ramirezlopez, P.D. Lee, B. Santillana, B.G. Thomas, and R. Morales: Ironmaking Steelmaking, 2014, vol. 41, pp. 242–49.

J. Yang, Z. Cai, and M. Zhu: ISIJ Int., 2018, vol. 58, pp. 299–308.

B.G. Thomas and L. Zhang: ISIJ Int., 2001, vol. 41, pp. 1181–93.

P. Ramírez-López, L.G. Demedices, O. Dávila, R. Sánchez-Pérez, and R.D. Morales: Metall. Mater. Trans. B, 2005, vol. 36, pp. 787–800.

R. Lopez and P. Ernesto: Imperial College London, London, 2010.

A. Jonayat and B.G. Thomas: Metall. Mater. Trans. B, 2014, vol. 45, pp. 1842–64.

X. Zhang, Q. Wang, W. Yang, S. Wang, and L. Zhang: Metall. Mater. Trans. B, 2018, vol. 49, pp. 2533–49.

X. Zhang, Y. Ren, and L. Zhang: Metall. Mater. Trans. A, 2018, vol. 49, pp. 5469–77.

Acknowledgments

The authors are grateful for support from the National Science Foundation China (Grants 51725402 and 51504020), the Fundamental Research Funds for the Central Universities (Grants FRF-TP-15-001C2 and 2015021642901), Beijing Key Laboratory of Green Recycling and Extraction of Metals (GREM), and the High Quality Steel Consortium (HQSC) at the School of Metallurgical and Ecological Engineering at the University of Science and Technology Beijing (USTB), China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 29, 2018.

Rights and permissions

About this article

Cite this article

Zhang, X., Chen, W., Ren, Y. et al. Mathematical Modeling on the Influence of Casting Parameters on Initial Solidification at the Meniscus of Slab Continuous Casting. Metall Mater Trans B 50, 1444–1460 (2019). https://doi.org/10.1007/s11663-019-01570-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01570-8