Abstract

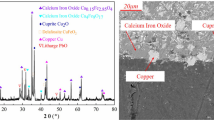

During ISA copper smelting process, ISASMELT furnace discharges a large amount of matte and slag mixture and the separation of them has an important influence on the recovery of valuable metals. This paper presented a reduction-sulfurization sedimentation process for recovering copper and cobalt from the matte–slag mixture of ISA furnace. Firstly, matte–slag mixture and traditional static sedimentation slag are characterized to determine their mineral composition and occurrence state. It indicates that Cu is primarily lost in slag in the form of sulfide, while Co is mostly lost in the form of oxide. With coke and pyrite as the reducing agent and vulcanizing agent, an orthogonal laboratory experiment was conducted to determine the effects of the smelting temperature and additive dosage on the recovery process. The optimum slag cleaning conditions were found to be: a coke dosage of 2 pct, a pyrite dosage of 2 pct, and a smelting temperature of 1260 °C lasting for 2 hours. In order to improve on the low utilization ratio of additives associated with the industrial sedimentation process, an innovative additive introducing method was put forward which enables the additives to mix and react with slag more adequately. A powder injection device was purpose-made to inject additives into molten slag in dispersion state, and a laboratory experiment was carried out to simulate this process. By injecting 2 pct coke and 2 pct pyrite, the contents of Cu and Co in cleaned slag decreased to 0.46 and 0.01 pct, respectively. It proves that the injection of additives into molten slag is an effective method to recover Cu and Co from the matte–slag mixture of ISA furnace.

Similar content being viewed by others

References

1. R. Matusewicz and E. Mounsey: JOM, 1998, vol. 50, pp. 51-52.

2. P. Vernon and S. Burks: J. S. Afr. Inst. Min. Metall., 1997, vol. 97, pp. 89-102.

3. Z.Z. He, J.Q. Qi: Modern Copper Metallurgy, Science Press, Beijing, BJ, 2003, pp. 289-95.

4. C. Arslan and F. Arslan: Hydrometallurgy, 2002, vol. 67, pp. 1-7.

5. R. Moskalyk and A. Alfantazi: Miner. Eng., 2003, vol. 16, pp. 893-919.

6. P.K. Gbor, V. Mokri, and C.Q. Jia: J. Environ. Sci. Health A, 2000, vol. 35, pp. 147-67.

7. H. Chikashi: Southern Africa Pyrometallurgy, Johannesburg, SA, March 2011, pp. 185-98.

8. E. Rudnik, L. Burzyńska, and W. Gumowska: Miner. Eng., 2009, vol. 22, pp. 88-95.

9. Y. Li, V.G. Papangelakis, and I. Perederiy: Hydrometallurgy, 2009, vol. 97, pp. 185-93.

10. A.H. Kaksonen, L. Lavonen, M. Kuusenaho, A. Kolli, H. Närhi, E. Vestola, J.A. Puhakka, and O.H. Tuovinen: Miner. Eng., 2011, vol. 24, pp. 1113-21.

11. J.H. Heo, B.S. Kim, and J.H. Park: Metall. Mater. Trans B, 2013, vol. 44, pp. 1352-63.

12. H. Shen and E. Forssberg: Waste Manage., 2003, vol. 23, pp. 933-49.

13. A. Sarrafi, B. Rahmati, H. Hassani, and H. Shirazi: Miner. Eng., 2004, vol. 17, pp. 457-59.

14. C. Tang, Y. Li, S. Yang, Y. Chen, L. Ye, and W. Zhang: Nonferr. Met., 2015, vol. 1, pp. 1-5.

15. D. Busolic, F. Parada, R. Parra, M. Sanchez, J. Palacios, and M. Hino: Min. Process. Extr. Metall., 2011, vol. 120, pp. 32-36.

16. X.J. Zhai, N.J. Li, X. Zhang, F. Yan, and L. Jiang: Trans. Nonferrous Met. Soc. China, 2011, vol. 21, pp. 2117-21.

17. S. Hughes: JOM, 2000, vol. 52, pp. 30-33.

18. Y. Li, Y. Chen, C. Tang, S. Yang, J. He, and M. Tang: J. Hazard Mater., 2017, vol. 322, pp. 402-12.

19. S. Mikhail and A. Webster: Canadian metallurgical quarterly, 1992, vol. 31, pp. 269-81.

20. T. Mitsuo, T. Shoji, Y. Hatta, H. Ono, H. Mori, and T. Kai: Trans. Jap. Inst. Metals, 1982, vol. 23, pp. 768-79.

21. Y. Okada, S. Fukagawa, K. Maya, H. Ikemiya, and K. Shinme: Rev. Metall., 1994, vol. 91, pp. 923-30.

22. W.H. Yang and Y.S. Tarng: J. Mater. Process. Technol., 1998, vol. 84, pp. 122-29.

23. X. Wu and D.Y. Leung: Appl. Energy, 2011, vol. 88, pp. 3615-24.

24. R.K. Roy: Design of experiments using the Taguchi approach: 16 steps to product and process improvement, John Wiley & Sons, New York, NY, 2001, pp. 15-29.

25. D. M. Byrne and S. Taguchi: Quality Progress, 1987, vol. 20, pp. 19-26.

26. L. Burzyńska, W. Gumowska, and E. Rudnik: Hydrometallurgy, 2004, vol. 71, pp. 447-55.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Nos. 51834008, 51874040, 51504022); the Fundamental Research Funds for the Central Universities (Nos. FRF-TP-17-036A2, 230201606500078).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted April 11, 2018.

Rights and permissions

About this article

Cite this article

Yang, X., Zhang, J., Zhang, J. et al. Efficient Recovery of Copper and Cobalt from the Matte–Slag Mixture of ISA Furnace by Injection of Coke and Pyrite. Metall Mater Trans B 49, 3118–3126 (2018). https://doi.org/10.1007/s11663-018-1396-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1396-3