Abstract

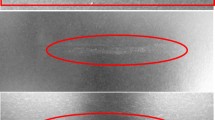

To understand the mechanism for the entrapment of non-metallic inclusions by curved hooks beneath the surface of continuous casting slabs, the etching of the slab, the observation of hooks and the detection of inclusions on sections vertical and parallel to the slab surface were performed. The location of inclusions and hooks was revealed, and forces acting on the inclusion below a hook were analyzed. Inclusions gathered more below the curved hook than in the overflow zone above the hook. From the observation of hooks and inclusions on sections vertical to the slab surface, the number density of 3 to 5 μm inclusions in the hook zone and no-hook zone was very close, while the number density of > 10 μm inclusions in the hook zone was larger than that in the no-hook zone. From the observation on sections parallel to the slab surface, > 20 μm inclusions were located near the hook line more than in other regions, and the number density of inclusions in the hook zone was more than that in the no-hook zone. The apparent friction coefficient dominated the critical capturing size of inclusions from the solidification front, and the deflection angle, flow velocity, sulfur content and solidification velocity had influences on the size range.

Similar content being viewed by others

References

Q. Zhang, L. Wang and X. Wang: ISIJ Int., 2006, vol. 46, pp. 1421-26.

A. Kumar, S.K. Choudhary and S.K. Ajmani: ISIJ Int., 2012, vol. 52, pp. 2305-07.

L. Zhang and B.G. Thomas: ISIJ Int., 2003, vol. 43, pp. 271-91.

T. Miyake, M. Morishita, H. Nakata and M. Kokita: ISIJ Int., 2006, vol. 46, pp. 1817-22.

H. Esaka, Y. Kuroda, K. Shinozuka and M. Tamura: ISIJ Int., 2004, vol. 44, pp. 682-90.

H. Shibata, H. Yin, S. Yoshinaga, T. Emi and M. Suzuki: ISIJ Int., 1998, vol. 38, pp. 149-56.

A.V. Catalina, S. Mukherjee and D. Stefanescu: Metall. Mater. Trans. A, 2000, vol. 31, pp. 2559-68.

D. Stefanescu and A. Catalina: ISIJ Int., 1998, vol. 38, pp. 503-05.

Y. Awajiya, J. Kubota and S. Takeuchi: AISTech 2005 Iron and Steel Technology Conf. Proc., Kinki, JP, The Association for Iron and Steel Technology (AIST), Warrendale, PA, 2005. vol. II pp. 65–75.

X. Deng, L. Li, X. Wang, Y. Ji, C. Ji and G. Zhu: Int. J. Mine. Metall. Mater., 2014, vol. 21, pp. 531-43.

J. Sengupta, B.G. Thomas, H. Shin, G. Lee and S. Kim: Metall. Mater. Trans. A, 2006, vol. 37, pp. 1597-1611.

T. Emi, H. Nakato, Y. Iida, K. Emoto, R. Tachibana, T. Imai and H. Bada: Proc. Nat. Open Hearth and Basic Oxygen Steel Conf., 1978. vol. 61, pp. 350–60.

H. Yamamura, Y. Mizukami and K. Misawa: ISIJ Int., 1996, vol. 36, pp. S223-S26.

E. Takeuchi and J. Brimacombe: Metall. Trans. B, 1984, vol. 15B, pp. 493-509.

E. Takeuchi and J. Brimacombe: Metall. Trans. B, 1985, vol. 16, pp. 605-25.

E. Szekeres: Iron Steel Eng., 1996, vol. 73, pp. 29-37.

J. Sengupta, H. Shin, B.G. Thomas and S. Kim: Acta Mater., 2006, vol. 54, pp. 1165-73.

G. Lee, B.G. Thomas, S. Kim, H. Shin, S. Baek, C. Choi, D. Kim and S. Yu: Acta Mater., 2007, vol. 55, pp. 6705-12.

Y. Meng and B.G. Thomas: Metall. Mater. Trans. B, 2003, vol. 34, pp. 707-25.

C. Cicutti and R. Boeri: ISIJ Int., 2001, vol. 41, pp. 311-13.

H. Yamamura and Y. Mizukami: CAMP-ISIJ, 1991, vol. 4, pp. 1250.

G.V. Voort: Mater. Charact., 1995, vol. 35, pp. 135-37.

Y. Ren, Y. Wang, S. Li, L. Zhang, X. Zuo, S.N. Lekakh and K. Peaslee: Metall. Mater. Trans. B, 2014, vol. 45, pp. 1291-1303.

G. Lee, H. Shin, S. Kim, S. Kim, W. Choi and B.G. Thomas: Ironmaking Steelmaking, 2009, vol. 36, pp. 39-49.

K. Mukai and M. Zeze: Steel Res. Int., 2003, vol. 74, pp. 131-38.

K. Mukai and W. Lin: Braz. Arch. Biol. Techn., 1994, vol. 55, pp. 257-62.

K. Mukai and W. Lin: Tetsu- to- Hagane, 1994, vol. 80, pp. 533-38.

T. Yokoyama, Y. Ueshima, K. Sasai, Y. Mizukami, H. Kakimi and M. Kato: Tetsu- to- Hagane, 1997, vol. 83, pp. 563-68.

L. Zhang, J. Aoki and B.G. Thomas: Metall. Mater. Trans. B, 2006, vol. 37, pp. 361-79.

K. Mukai, M. Zeze and T. Morohoshi: Mater. Science Forum, 2006, vol. 508, pp. 211-220.

Acknowledgments

The authors are grateful for support from the National Key R&D Program of China (2017YFB0304000&2017YFB0304001), National Natural Science Foundation of China (Grant Nos. 51725402, 51504020 and 51704018), the Fundamental Research Funds for the Central Universities (Grant Nos. FRF-TP-15-001C2, FRF-TP-15-067A1, FRF-TP-17-039A1 and FRF-BD-17-010A), Guangxi Key Research and Development Plan (Grant No. AB17129006), National Postdoctoral Program for Innovative Talents (Grant No. BX201700028), Young Elite Scientists Sponsorship Program by CAST (No. 2017QNRC001), China Postdoctoral Science Foundation (No. 2017M620016), Beijing Key Laboratory of Green Recycling and Extraction of Metals (GREM) and the High Quality steel Consortium (HQSC) and Green Process Metallurgy and Modeling (GPM2) at the School of Metallurgical and Ecological Engineering at University of Science and Technology Beijing (USTB), China.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted February 5, 2018.

Rights and permissions

About this article

Cite this article

Zhang, X., Ren, Y., Zhang, L. et al. Entrapment of Inclusions by Solidified Hooks at the Subsurface of Ultra-Low-Carbon Steel Slab. Metall Mater Trans B 49, 3186–3199 (2018). https://doi.org/10.1007/s11663-018-1366-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1366-9