Abstract

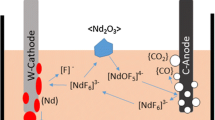

Nowadays, neodymium is almost solely produced by the electrochemical reduction of Neodymium oxide in fused fluoride salts. Thereby, the fluid flow distribution within the electrolysis cell is important for the productivity and efficiency of the process. In this work, the flow field within a conventional cell with vertical electrodes is compared to that of an innovative cell concept with horizontal electrodes by computational fluid dynamics. The numerical model uses the Eulerian volume of fluid approach to track phase boundaries between the continuous phases, while the Lagrangian discrete phase model is applied to compute the rising trajectories of emitted off-gas bubbles. The calculated results indicate that the new cell type is more suitable for the efficient, large-scale production of neodymium, since there is potential to decrease the cell voltage and enhance the current efficiency. By that, the specific energy consumption can be lowered significantly. However, an advanced level of automation is necessary to operate the new cell.

Similar content being viewed by others

References

C.K. Gupta and N. Krishnamurthy: Extractive Metallurgy of Rare Earth, CRC Press, Boca Raton, FL, 2005.

S. Pang, S. Yan, Z. Li, D. Chen, L. Xu, and B. Zhao: Chin. J. Rare Met., 2011, vol. 35, pp. 440–450 (translated from Chinese by Que Z).

K. Liu, J. Chen, and X. Wei: Chin. J. Nonferrous Met., 2001, vol. 11, pp. 99–101 (translated from Chinese by Pan Q).

H. Vogel, B. Flerus, F. Stoffner, and B. Friedrich: J. Sustainable Metall.—Special Issue: Rare Earths, 2016

K. Liu, J. Chen, and X. Wei: Chin. Rare Earths, 2001, vol. 22, pp. 30–33 (translated from Chinese by Pan Q).

Z. Zhang, X. Liang, J. Ju, and G. Xu: Chinese Society of Rare Earth—Conf. Proc. 2000, pp. 207–11 (translated from Chinese by Wang J).

D. Chen, S. Yan, Z. Li, S. Pang, L. Xu, and X. Guo: J. Chin. Rare Earth Soc., 2011, vol. 29, pp. 769–72 (translated from Chinese by Que Z).

J. Wang, Z. Zhang, G. Tu, and W. Wu: Chin. Rare Earths, 2012, vol. 33, pp. 64–67 (translated from Chinese by Que Z).

Y. Ren, X. Kong, and L. Xie: J. Rare Earths, 2004, vol. 22, pp. 252–56.

S. Fu: J. Chin. Rare Earth Soc., 2007, vol. 25, pp. 71–76 (translated from Chinese by Pan Q).

C.W. Hirt and B.D. Nichols: J. Comput. Phys., 1981, vol. 39, pp. 201–25

K. Liu, J. Chen, and X. Wei: Rare Met. Cemented Carbides, 2000, vol. 143, p. 7 (translated from Chinese by Pan Q).

K. Liu, J. Chen, X. Wei, T. Zheng, L. Xie, and X. Kong: Chin. Rare Earths, 2000, vol. 21, pp. 37–39 (translated from Chinese by Pan Q).

M. Alam, W. Yang, K. Mohanarangam, G. Brooks, and Y. Morsi: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 1155–65.

T. Frank, J. Shi, and A.D. Burns: 3rd Int. Symp. on Two-Phase Flow Modelling and Experimentation, Pisa, 2004.

A. Tomiyama, I. Kataoka, I. Zun, and T. Sakaguchi: JSME Int. J. Ser. B Fluids Thermal Eng., 1998, vol. 41, pp. 472–79.

A.W.G. de Vries, A. Biesheuvel, and L. van Wijngaarden: Int. J. Multiphase Flow, 2002, vol. 28, pp. 1823–35.

C. Brücker: Phys. Fluids, 1999, vol. 11, pp. 1781–96.

Yuqing Feng, M. Philip Schwarz, William Yang, and Mark Cooksey: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1959–81.

M. Ishii and N. Zuber: AIChE J., 1979, vol. 25, pp. 843–55.

L. Schiller and A.Z. Naumann: Ver. Deut. Ing., 1933, vol. 77, pp. 318–20.

F. Peebles and H. Garber: Chem. Eng. Progr., 1953, vol. 49, pp. 88–97.

G. Bozzano and M. Dente: Comput. Chem. Eng., 2001, vol. 25, pp. 571–76.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 5, 2016.

Rights and permissions

About this article

Cite this article

Haas, T., Hilgendorf, S., Vogel, H. et al. A Comparison between Two Cell Designs for Electrochemical Neodymium Reduction Using Numerical Simulation. Metall Mater Trans B 48, 2187–2194 (2017). https://doi.org/10.1007/s11663-017-0982-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-0982-0