Abstract

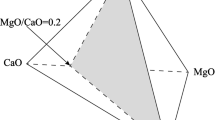

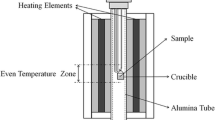

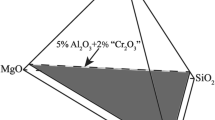

The “FeO”-containing slags play an important role in the operation of an ironmaking blast furnace (BF), in particular the primary slags such as the system “FeO”-CaO-SiO2-Al2O3-2 mass pct MgO with CaO/SiO2 weight ratios of 1.3, 1.5, and 1.8 saturated with metallic iron. To investigate the characteristics of such a slag system and its behavior in BF, the phase equilibria and liquidus temperatures in the slag system have been experimentally determined using the high-temperature equilibration and quenching technique followed by an electron probe X-ray microanalysis (EPMA). Isotherms between 1553 K and 1603 K (1280 °C and 1330 °C) were determined in the primary phase fields of dicalcium silicate, melilite, spinel, and monoxide [(Mg,Fe2+)O]. Pseudo-ternary phase diagrams of (CaO + SiO2)-Al2O3-“FeO” with a fixed MgO concentration at 2 mass pct and at CaO/SiO2 ratios of 1.3, 1.5, and 1.8 have been discussed, respectively, simplifying the complexity of the slag system for easy understanding and applying in BF operation. It was found that the liquidus temperatures increase in melilite and spinel primary phase fields, but decrease in dicalcium silicate and monoxide primary phase fields with increasing Al2O3/(CaO + SiO2) ratio. In addition, the liquidus temperatures decrease with increasing “FeO” concentration in dicalcium silicate and melilite primary phase fields, while showing an increasing trend in the spinel and monoxide primary phase fields. The data resulted from this study can be used to improve and optimize currently available database of thermodynamic models used in FactSage.

Similar content being viewed by others

References

M. Hino, T. Nagasaka, A. Katsumata, K.I. Higuchi, K. Yamaguchi, N. Kon-No, Metall. Trans. B 30B, 671–83 (1999)

M. Matsumura, M. Hoshi, T. Kawaguchi, ISIJ Int. 45, 594–602 (2005)

V. Shatokha, O. Velychko, High Temp. Mater. Proc. 31, 215–20 (2012)

X. Ma, G. Wang, S. Wu, J. Zhu, B. Zhao, ISIJ Int. 55, 2310–17 (2015)

X. Ma, D. Zhang, Z. Zhao, T. Evans, B. Zhao, ISIJ Int. 56, 513–19 (2016)

M. Kou, S. Wu, X. Ma, L. Wang, M. Chen, Q. Cai, B. Zhao, Metall. Trans. B 47B, 1093–02 (2016)

K. Jang, X. Ma, G. Wang, S. Wu, J. Zhu, B. Zhao, ISIJ Int. 56, 967–76 (2016)

K. Jang, X. Ma, G. Wang, S. Wu, J. Zhu and B. Zhao: ISIJ Int. (In Press). doi:10.2355/isijinternational.ISIJINT-2016-342.

A.K. Biswas, Principles of Blast Furnace Ironmaking: Theory and Practice (Cootha Publishing House, Brisbane, 1981), p. 329

M. Geerdes, R. Chaigneau, I. Kurunov, Modern Blast Furnace Ironmaking: An Introduction, 3rd edn. (IOS Press, Amsterdam, 2015), p. 59

M. Hayashi, K. Suzuki, Y. Maeda, T. Watanabe, ISIJ Int. 55, 1223–31 (2015)

K. Yamaguchi, H. Ueno, T. Kawaguchi, S. Matsunaga, H. Oda, S. Amano, ISIJ Int. 34, 964–72 (1994)

K. Higuchi, M. Naito, M. Nakano, Y. Takamoto, ISIJ Int. 44, 2057–66 (2004)

M. Hayashi, K. Suzuki, Y. Maeda, T. Watanabe, ISIJ Int. 56, 220–25 (2016)

K. Jang, X. Ma, G. Wang, S. Wu, J. Zhu and B. Zhao: Proc. of 10th CSM Steel Congress and the 6th Baosteel Biennial Academic Conference, Metallurgical Industry Press, Shanghai, 2015, p. 0707.

V.D. Eisenhuttenleute, Slag Atlas (Verlag Sthaleisen GmbH, Düsseldorf, 1995), pp. 156–60

N.L. Bowen, J.F. Schairer, Am. J. Sci. 24, 177–213 (1932)

N.L. Bowen, J.F. Schairer, E. Posnjak, Am. J. Sci. 26, 193–284 (1933)

N.L. Bowen, J.F. Schairer, E. Posnjak, Am. J. Sci. 25, 273–94 (1933)

W.C. Allen, R.B. Snow, J. Am. Ceram. Soc. 38, 264–72 (1955)

N.L. Bowen, J.F. Schairer, Am. J. Sci. 29, 151–217 (1935)

J.F. Schairer, K. Yagi, Am. J. Sci. 245, 193–204 (1947)

A. Muan, E.F. Osborn, Phase Equilibria among Oxides in Steelmaking (Addison-Wesley, New York, 1951), p. 325

D.P. Kalmanovitch and J. Williamson: Proc. ACS Symp. Ser. 301, American Chemical Society, Washington DC, 1986, pp. 234–255.

D.P. Kalmanovitch, A. Sanyal, J. Williamson, J. Inst. Energy 59, 20–23 (1986)

Acknowledgments

The authors would like to thank Baosteel through the Baosteel-Australia Joint Research and Development Centre (BAJC) for providing financial support for this project. The authors are also grateful to Mr Ron Rasch and Ms Ying Yu of the Centre for Microscopy and Microanalysis at UQ, who provided technical support for the EPMA facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 23, 2016.

Rights and permissions

About this article

Cite this article

Jang, Ko., Ma, X., Zhu, J. et al. Phase Equilibria in the System “FeO”-CaO-SiO2-Al2O3-MgO at Different CaO/SiO2 Ratios. Metall Mater Trans B 48, 1547–1560 (2017). https://doi.org/10.1007/s11663-017-0955-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-0955-3