Abstract

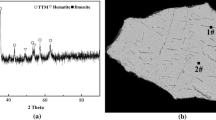

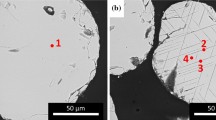

The oxidation behaviors of South Africa (SA) titanomagnetite (TTM) and its effects on the gas solid reduction in the fluidized bed were investigated on the basis of the two-stage short process of direct reduction–electric arc furnace (DR-EAF) melting separation. The results showed that the oxidation phase transformations in the high-temperature range from 1073 K to 1223 K (800 °C to 950 °C) can be divided into two typical processes: with the fast generation of pseudobrookite and with the maghemite generation at the initial stage. The reduction efficiency for SA TTM was improved by the preoxidation treatment, mainly because of the dissociation of titania-ferrous oxides to the easy reducible hematite. However, at a preoxidation temperature higher than 1173 K (900 °C), the improving effect became weak, due to high-temperature sintering and the larger crystallite size of oxidation products. There is an extreme value of the preoxidation influence, and the optimum preoxidation time is different for various temperatures. The reduction metallization degree of SA TTM can be relatively improved by 14.5 and 4.5 pct for the first and second reduction steps, respectively, by 1173 K (900 °C) preoxidation with an optimum time of 30 minutes. Finally, the equilibrium relationship between the metallization degree and the gas reduction potential for TTM ore with preoxidation treatment was built.

Similar content being viewed by others

References

S.L. Yang and J.F. Sheng: Technology of Pig Iron and Titanium Slag Smelting, Metallurgy Industry Press, Beijing, 2006.

U.S. Geological Survey: USGS Mineral Commodity Summaries 2015, Unit State Geologic, Washington, DC, 2015.

H.Y. Sun, J.S. Wang, X.J. Dong, and Q.G. Xue: Met. Int., 2012, vol. 17 (7), pp. 49–56.

J.L. Zhang, Z.J. Liu, and T.J. Yang: Non-Blast Furnace Ironmaking, Metallurgy Industry Press, Beijing, 2015.

E. Park, S.B. Lee, O. Ostrovski, D.J. Min, and C. H. Rhee: ISIJ Int., 2004, vol. 44 (1), pp. 214–16.

J.O. Edstrom: J. Iron Steel Inst., 1953, vol. 175, No. 3, pp. 289–304.

K. Sun, R. Takahash, and J. Yagi: ISIJ Int., 1992, vol. 32 (9), pp. 953–61.

P.L. Vijay, R. Venugopalan, and D. Sathiyamoorthy: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 731–38.

S.K. Gupta, V. Rajkumar, and P. Grieveson: Can. Metall. Q., 1990, vol. 29 (1), pp. 43–49.

D.G. Jones: J. Appl. Chem. Biotechnol., 1975, vol. 25 (8), pp. 561–82.

R. Merk and C.A. Pickles: Can. Metall. Q., 1988, vol. 27 (3), pp. 179–85.

C. Standard: The Ferric Chloride-Sodium Acetate Volumetric Method for the Determination of Metallic Iron Content (GB 6730.6-86), China Standards Press, Beijing, 1987.

X.M. Liu, J. Shaw, J.Z. Jiang, J. Bloemendal, P. Hesse, T. Rolph, and X.G. Mao: Sci. China Earth Sci., 2010, vol. 40, No. 5, pp. 592–602.

K.J. Gallagher, W. Feitknecht, and U. Mannweiler: Nature, 1968, vol. 217, pp. 1118–21.

X. Fu, Y. Wang, and F. Wei: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 1338–48.

J.B. Zhang, Q.S. Zhu, Z.H. Xie, C. Lei, and H.Z. Li: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 897–905.

D.B. Rao and M. Rigaud: Oxid. Met., 1975, vol. 9 (1), pp. 99–116.

J.B. Zhang, G.Y. Zhang, Q.S. Zhu, C. Lei, Z.H. Xie, and H.Z. Li: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 914–22.

H.Y. Sun, A.A. Adetoro, Z. Wang, F. Pan, and L. Li: ISIJ Int., 2016, vol. 56 (6), pp. 935–42.

H.Y. Sun, J.S. Wang, L.J. Cao, and Q.G. Xue: Trans. Mater. Heat Treatment, 2012, vol. 33 (9), pp. 1–6.

G. Zhang and O. Ostrovski: Int. J. Miner. Process., 2002, vol. 64 (4), pp. 201–18.

Acknowledgments

The authors are grateful for the financial support from the National Natural Science Foundation of China (Grant No. 51404228), the National Outstanding Youth Science Fund Project of NSFC (Grant No. 21325628), National Program on Key Basic Research Project of China (973 Program) No. 2013CB632603 and Chinese Academy of Sciences—The World Academy of Sciences (CAS-TWAS) President Fellowship.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted November 27, 2016.

Rights and permissions

About this article

Cite this article

Sun, H., Adetoro, A.A., Pan, F. et al. Effects of High-Temperature Preoxidation on the Titanomagnetite Ore Structure and Reduction Behaviors in Fluidized Bed. Metall Mater Trans B 48, 1898–1907 (2017). https://doi.org/10.1007/s11663-017-0925-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-0925-9