Abstract

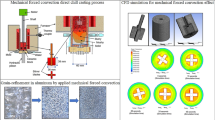

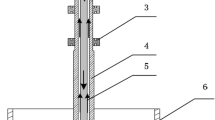

A three-dimensional CFD model coupled with melt flow, heat transfer, and thermal contraction was developed to simulate the direct-chill (DC) casting process of A390 alloy hollow billet with a cross-section size of Φ164 mm/Φ60 mm. This study considered the effects of contact height and air gap width between the core and the hollow billet, which dominated the heat transfer at the inner wall of the hollow billet. The effects of core taper angle, relative vertical position of core in the mold, and casting speed on the steady-state temperature distribution and formability of hollow billet were investigated. According to the criterion used in this study, the optimal core taper angle is 3 deg for DC casting of A390 alloy hollow billet. With the optimal core taper angle, the A390 alloy hollow billet can be cast successfully regardless of the variation of the relative vertical position of core in the mold and casting speed. The coupled model developed in this study can be applied to optimize the core taper angle and study the effects of casting parameters in various dimensions of hollow billet.

Similar content being viewed by others

Abbreviations

- A :

-

A constant value

- B :

-

A constant value

- C 1 :

-

A constant value

- C 2 :

-

A constant value

- [D]e :

-

Elastic stiffness matrix

- f s :

-

Solid fraction

- g :

-

Gravitational acceleration

- G k :

-

Generation of turbulent kinetic energy

- H :

-

Enthalpy

- H 0 :

-

Initial contact height

- H contact :

-

Contact height

- H total :

-

Total height of hollow billet

- h :

-

Heat transfer coefficient

- h contact :

-

Good thermal contact coefficient

- h gap :

-

Poor thermal contact coefficient

- i :

-

Iteration number

- K :

-

Permeability

- K 0 :

-

Initial permeability

- k :

-

Turbulent kinetic energy

- L :

-

Differential operator

- P :

-

Pressure

- r core :

-

Radius of Cu core

- T :

-

Current temperature

- T coh :

-

Reference temperature

- T l :

-

Liquidus

- T s :

-

Solidus

- t :

-

Time

- V :

-

Velocity

- V s :

-

Casting speed

- (x 1, y 1, z 1):

-

Coordinate at the inner wall

- α(T):

-

Thermal expansion coefficient

- β :

-

Volume expansion coefficient at temperature T 0

- δ :

-

Small positive number

- δ air :

-

Air gap width

- ΔT :

-

Temperature difference

- ε :

-

Turbulent dissipation rate

- {ε}:

-

Total strain vector

- θ :

-

Core taper angle

- λ :

-

Thermal conductivity

- λ air :

-

Thermal conductivity of air

- μ l :

-

Laminar viscosity

- μ t :

-

Turbulent viscosity

- ν :

-

Poisson’s ratio

- ρ :

-

Density at temperature T 0

- {σ}:

-

stress vector

- σ k :

-

Turbulent Prandtl numbers for k

- σ ε :

-

Turbulent Prandtl numbers for ε

- χ :

-

Very small positive number

References

D. G. Eskin: Physical Metallurgy of Direct Chill Casting of Aluminum Alloys, p. 1-18, CRC Press, Boca Raton, 2008.

2.D. C. Weckman and P. Niessen: Can. Metall. Quart., 1984, vol. 23, pp. 209-16.

3.M. R. Aboutalebi, M. Hasan, and R. I. L. Guthrie: Numer. Heat Transfer A,1995, vol. 28, pp. 279-297.

4.D. Mortensen: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 119-33.

5.C. J. Vreeman, J. D. Schloz, and M. J. M. Krane: Trans. ASME, J. Heat Transfer, 2002, vol. 124, pp. 947-53.

6.L. Begum and M. Hasan: Numer. Heat Transfer A, 2015, vol. 67, pp. 719-45.

7.K. Ho and R. D. Pehlke: Metall. Trans. B, 1985, vol. 16, pp. 585-94.

8.R. W. Lewis and R. S. Ransing: Metall. Mater. Trans. B, 1998, vol. 29B, pp. 437-48.

9.M. Trovant and S. Argyropoulos: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 75-86.

10.A. Prasad and I. Bainbridge: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 456-68.

11.J. P. Verwijs and D. C. Weckman: Metall. Trans. B, 1988, vol. 19, pp. 201-12.

12.H. Huang, V. K. Suri, J. L. Hill, and J. T. Berry: J. Eng. Mater. Technol. Trans. ASME, 1993, vol, 115, pp. 2-7.

P. Chow, C. Bailey, M. Cross, and K. Pericleous: in Modelling of Casting, Welding and Advanced Solidification Processes VII, London, TMS, Warrendale, PA, 1995, pp. 213–21.

14.A. R. Baserinia, H. Ng, D. C. Weckman, M. A. Wells, S. Barker, and M. Gallerneault: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 887-901.

15.A. R. Baserinia, E. J. F. R. Caron, M. A. Wells, D. C. Weckman, S. Barker, and M. Gallerneault,: Metall. Mater. Trans. B, 2013, vol. 44B, 1017-29.

16.W. D. Bennon and F. P. Incropera: Int. J. Heat Mass Transfer, 1987, vol. 30, pp. 2161-70.

17.W. D. Bennon and F. P. Incropera: Int. J. Heat Mass Transfer, 1987, vol. 30, pp. 2171-87.

18.S. Asai and I. Muchi: Trans. Iron Steel Inst. Jap., 1978, vol. 18, pp. 90-8.

19.H. T. Zhang, H. Nagaumi, Y. B. Zuo, and J. Z. Cui: Mater. Sci. Eng. A, 2007, vol. 448, pp. 189-203.

20.B. E. Launder and B. I. Sharma: Lett. Heat Mass Transfer, 1974, vol. 1, pp. 131-7.

E.K. Jensen: in Light Metals 1980, TMS, Warrendale, PA, 1980, pp. 631–42.

G.U. Grün, I. Eick, and D. Vogelsang: in Light Metals 1994, TMS, Warrendale, PA, 1994, pp. 863–68.

Y. Watanade and N. Hayashi: in Light Metals 1996, TMS, Warrendale, PA, 1996, pp. 979–84.

24.M. A. Wells, D. Li, and S. L. Cockcroft: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 929-39.

25.R. Abid: Int. J. Eng. Sci, 1993, vol. 31, pp. 831-40.

26.M. G. Chu and D. A. Granger: Mater. Sci. Forum, 1996, vol. 217-222, pp. 1505-10.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51204046) and the Fundamental Research Funds for the Central Universities (No. N130409003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 21, 2016.

Rights and permissions

About this article

Cite this article

Zuo, K., Zhang, H., Qin, K. et al. Three-Dimensional CFD Simulation Coupled with Thermal Contraction in Direct-Chill Casting of A390 Aluminum Alloy Hollow Billet. Metall Mater Trans B 48, 429–443 (2017). https://doi.org/10.1007/s11663-016-0857-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0857-9