Abstract

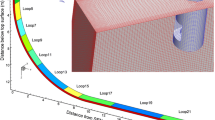

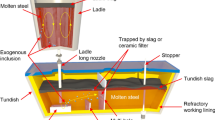

In the current study, the three-dimensional fluid flow, heat transfer, and solidification in steel centrifugal continuous casting strands were simulated. The volume of fluid model was used to solve the multiphase phenomena between the molten steel and the air. The entrapment and final distribution of inclusions in the solidified shell were studied with the discussion on the effect of rotation behavior of the caster system. Main results indicate that after applying the rotation of the shell, the fluid flow transformed from a recirculation flow to a rotation flow in the mold region and was driven to flow around in the casting direction. As the distance below the meniscus increased, the distribution of the tangential speed of the flow and the centrifugal force along one diameter of the strand became symmetrical gradually. The jet flow from the nozzle hardly impinged on the same location on the shell due to the rotation of the shell during solidification. Thus, the shell thickness on the same height was uniform around, and the thinning shell and a hot spot on the surface of shell were avoided. Both of the measurement and the calculation about the distribution of oxide inclusions along the radial direction indicated the number of inclusions at the side and the center was more than that at the quarter on the cross section of billet. With a larger diameter, inclusions tended to be entrapped toward the center area of the billet.

Similar content being viewed by others

References

[1] J. E. Lait, J. K. Brimacombe, F. Weinberg. Mathematical modelling of heat flow in the continuous casting of steel. Ironmaking and Steelmaking, 1974, 1(2): 90-97.

[2] V. R. Voller, C. R. Swaminathan, Brian G. Thomas. Fixed grid techniques for phase change problems. A review. International Journal for Numerical Methods in Engineering, 1990, 30(4): 875-898.

[3] V. R. Voller, A. D. Brent, C. Prakash. Modelling the mushy region in a binary alloy. Applied Mathematical Modelling, 1990, 14(6): 320-320.

[4] J. S. Hsiao. An efficient algorithm for finite-difference analyses of heat transfer with melting and solidification. Numerical Heat Transfer, 1985, 8(6): 653-666.

H. Nam, H.-S. Park, J. K. Yoon. Numerical analysis of fluid flow and heat transfer in the funnel type mold of a thin slab caster. ISIJ Int, 2000, 40(9): 886-892.

H.-S. Park, H. Nam, J. K. Yoon. Numerical analysis of fluid flow and heat transfer in the parallel type mold of a thin slab caster. ISIJ Int., 2001, 41(9): 974-980.

[7] A. D. Brent, V. R. Voller, K. T. J. Reid. Enthalpy-porosity technique for modeling convection-diffusion phase change: application to the melting of a pure metal. Numerical Heat Transfer, 1988, 13(3): 297-318.

[8] S. H. Seyedein, M. Hasan. A three-dimensional simulation of coupled turbulent flow and macroscopic solidification heat transfer for continuous slab casters. International Journal of Heat and Mass Transfer, 1997, 40(18): 4405-4423.

[9] Shengtao Qiu, Heping Liu, Shiheng Peng, Yong Gan. Numerical analysis of thermal-driven buoyancy flow in the steady macro-solidification process of a continuous slab caster. ISIJ International, 2004, 44(8): 1376-1383.

[10] Saul Garcia-Hernandez, José de Jesús Barreto, Rodolfo D. Morales, Hugo Arcos-Gutierrez. Numerical simulation of heat transfer and steel shell growth in a curved slab mold. ISIJ International, 2013, 53(5): 809-817.

[11] Jianwei Yang, Yanping Du, Rong Shi, Xiaochao Cui. Fluid flow and solidification simulation in beam blank continuous casting process with 3D coupled model. Journal of Iron and Steel Research, International, 2006, 13(4): 17-21.

B.G. Thomas, Q. Yuan, R. Liu, S. Mahmood, R. Chaudhary: Transport and entrapment of particles in steel continuous casting. Proceedings of TMS Annual Meeting. 2012, pp. 279–86.

[13] Zhongqiu Liu, Baokuan Li, Li Zhang, Guodong Xu. Analysis of transient transport and entrapment of particle in continuous casting mold. ISIJ International, 2014, 54(10): 2324-2333.

[14] Shaowu Lei, Jiongming Zhang, Xinkai Zhao, Kai He. Numerical simulation of molten steel flow and inclusions motion behavior in the solidification processes for continuous casting slab. ISIJ International, 2014, 54(1): 94-102.

[15] Xiaopeng Song, Susen Cheng, Zijian Cheng. Numerical computation for metallurgical behavior of primary inclusion in compact strip production mold. ISIJ International, 2012, 52(10): 1824-1831.

[16] Yuji Miki, Hiroyuki Ohno, Yasuo Kishimoto, Sinya Tanaka. Numerical simulation on inclusion and bubble entrapment in solidified shell in model experiment and in mold of continuous caster with DC magnetic field. Tetsu-to-Hagane, 2011, 97(8): 423-432.

[17] Hong Lei, DianQiao Geng, JiCheng He. A continuum model of solidification and inclusion collision-growth in the slab continuous casting caster. ISIJ International, 2009, 49(10): 1575-1582.

[18] C. Pfeiler, Brian G. Thomas, M. Wu, A. Ludwig, A. Kharicha. Solidification and particle entrapment during continuous casting of steel. Steel Research International, 2006, 77(7): 1-10.

[19] Michele De Santis, Alessandro Ferretti. Thermo-fluid-dynamics modelling of the solidification process and behaviour of non-metallic inclusions in the continuous casting slabs. ISIJ International, 1996, 36(6): 673-680.

[20] Bernd Grimm, Peter Andrzejewski, K. Müller, K-H Tacke. Inclusions in continuously cast steel slabs-numerical model and validation. Steel Research, 1999, 70(10): 420-429.

[21] H. Nakata, T. Inoue, H. Mori, K. Ayata, T. Murakami, T. Kominami. Improvement of billet surface quality by ultra-high-frequency electromagnetic casting. ISIJ International, 2002, 42(3): 264-272.

[22] Lifeng Zhang, Yufeng Wang. Modeling the entrapment of nonmetallic inclusions in steel continuous-casting billets. JOM, 2012, 64(9): 1063-1074.

Q. Wang, L. Zhang, and S. Sridhar: Metall. Mater. Trans. B, 2016 (Unpublished manuscript).

Q. Wang, L. Zhang, S. Sridhar, S. Yang, W. Yang, Y. Wang: Metall. Mater. Trans. B, 2016, DOI:10.1007/s11663-016-0625-x.

[25] S. K. Choudhary, D. Mazumdar. Mathematical modelling of transport phenomena in continuous casting of steel. ISIJ International, 1994, 34(7): 584-592.

[26] J. Szekely, R. T. Yadoya. The physical and mathematical modelling of the flow field in the mold region in continuous casting systems: Part II. The mathematical representation of the turbulent flow field. Metallurgical Transactions, 1973, 4(5): 1379-1388.

[27] Brian G. Thomas, Lifeng Zhang. Mathematical modeling of fluid flow in continuous casting. ISIJ International, 2001, 41(10): 1181-1193.

[28] E. Loth. Numerical approaches for motion of dispersed particles, droplets and bubbles. Progress in Energy and Combustion Science, 2000, 26(3): 161-223.

[29] X. Huang, Brian G. Thomas, F. M. Najjar. Modeling superheat removal during continuous casting of steel slabs. Metallurgical Transactions B, 1992, 23(3): 339-356.

[30] M. R. R. I. Shamsi, S. K. Ajmani. Three dimensional turbulent fluid flow and heat transfer mathematical model for the analysis of a continuous slab caster. ISIJ International, 2007, 47(3): 433-442.

[31] ZakariaY Ahmad, TequilaA L. Harris. The effect of solidification on the casting window after bubble entrainment. Journal of Coatings Technology and Research, 2014, 11(1): 89-93.

[32] Lifeng Zhang, Jun Aoki, Brian G. Thomas. Inclusion removal by bubble flotation in a continuous casting mold. Metallurgical and Materials Transactions B, 2006, 37(3): 361-379.

[33] Q. Han, J. D. Hunt. Particle pushing: critical flow rate required to put particles into motion. Journal of Crystal Growth, 1995, 152(3): 221-227.

D. Shangguan, S. Ahuja, D. M. Stefanescu. Analytical model for the interaction between an insoluble particle and an advancing solid/liquid interface. Metall. Trans. A, 1992, 23: 669-680.

[35] D. R. Uhlmann, B. Chalmers, K. A. Jackson. Interaction between particles and a solid-liquid interface. Journal of Applied Physics, 1964, 35(10): 2986-2993.

D. M. Stefanescu, B. K. Dhindaw, S. A. Kacar, A. Moitra. Behavior of ceramic particles at the solid-liquid metal interface in metal matrix composites. Metallurgical Transactions A, 1988, 19: 2847-2855.

P.F. Auborg: Interactions of second phase particles with a crystal growing from the melt. MIT, 1978.

Acknowledgments

The authors are grateful for the support from the National Science Foundation China (Grant No. 51274034, No. 51504020, and No. 51404019), State Key Laboratory of Advanced Metallurgy, Beijing Key Laboratory of Green Recycling and Extraction of Metals (GREM), the Laboratory of Green Process Metallurgy and Modeling (GPM2), and the High Quality Steel Consortium (HQSC) at the School of Metallurgical and Ecological Engineering at University of Science and Technology Beijing (USTB), China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 2, 2015.

Rights and permissions

About this article

Cite this article

Wang, Q., Zhang, L. Determination for the Entrapment Criterion of Non-metallic Inclusions by the Solidification Front During Steel Centrifugal Continuous Casting. Metall Mater Trans B 47, 1933–1949 (2016). https://doi.org/10.1007/s11663-016-0661-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0661-6