Abstract

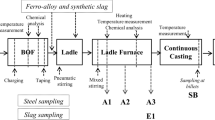

The effect of magnesium in the aluminum used as a deoxidizer on the cleanliness of steel was studied throughout a steelmaking route for the production of thin slabs. Two deoxidizers with different Mg contents were used. The Mg content of a “typical” deoxidizer was ~0.5 wt pct Mg, whereas that for an alternative deoxidizer was ~2 wt pct Mg. The inclusion population at different stages of the steelmaking process was characterized in terms of chemical composition, number, and size distribution. The inclusion modification path shows that the solid Al2O3 and Al2O3-MgO inclusions formed in the early stage of the steel ladle treatment are modified into Al2O3-MgO-CaO liquid and MgO-Al2O3-liquid inclusions. Although some slight differences were observed in the ladle furnace samples, the chemical composition of inclusions was similar in the samples taken at the mold of the continuous casting, regardless of the deoxidizer used. Gumbel, generalized extreme value (GEV), and generalized Pareto (GP) distributions were used for the description of the size distribution. The GEV and GP distributions resulted in proper distributions to describe the evolution of size distribution throughout the steelmaking process. Furthermore, no statistically significant differences between inclusion size distributions resulting from the use of either deoxidizer were found.

Similar content being viewed by others

References

P. Kaushik, J. Lehmann and M. Nadif, Metall. Mater. Trans. B, 2012, vol. 43, pp. 710-725.

E.B. Pretorius, H.G. Oltmann and B.T. Schart, An Overview of Steel Cleanliness From an Industry Perspective, in Aistech Conference Proceedings, 2013.

L.A. Frank, Castability—From Alumina to Spinels (and More), in 2001 Steelmaking Conference Proceedings, 2001.

G. Gao, M. Long, Y. Wang, X. Zuo and L. Zhang, Inclusions and Nozzle Clogging during Billet Continuous Casting Process, in Materials Science & Technology 2009 Conference and Exhibition, 2009.

E.B. Pretorious, H.G. Oltmann and T. Cash, Iron Steel Technol., 2010, vol 7, pp. 31-44.

T. Zhang, Y. Min, C. Liu and M. Jian, ISIJ Int., 2015, vol. 55, pp. 1541-1548.

H. V. Atkinson and G. Shi, Prog. Mater. Sci., 2003, vol. 48, pp. 457-520.

ASTM E2283-03, Standard Practice for Extreme Value Analysis of Nonmetallic Inclusions in Steel and Other Microstructural Features, ASTM International (2003).

Y. Murakami,, J. Res. Nat. Inst. Stand. Technol,1994, vol. 99, pp. 345-351.

Y. Murakami, Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions, Elsevier Science Ltd., Oxford UK, (2002), 321.

S. Beretta and Y. Murakami, Metall. Mater. Trans. B, 2001, vol. 32, pp. 517-523.

Y. Kanbe, A. Karasev, H. Todoroki and P. G. Jönsson, ISIJ Int., 2011, vol. 51, pp. 2056-2063.

J. Ekengren and J. Bergström, Extremes, 2012, vol. 15, pp. 257-265.

C. W. Anderson, G. Shi, H. V. Atkinson and C. M. Sellars, Acta Mater., 2000, vol. 48, pp. 4235-4246.

G. Shi, H. V. Atkinson, C. M. Sellars and C. W. Anderson, Acta Mater., 1999, vol. 47, pp. 1455-1468.

G. Shi, H. V. Atkinson, C. M. Sellars and C. W. Anderson, Ironmaking Steelmaking, 2000, vol. 27, pp. 355-360.

G. Shi, H. V. Atkinson, M. Sellars and C. W. Anderson, Ironmaking Steelmaking, 2000, vol. 27, pp. 361-366.

S. Beretta and Y. Murakami, Fatigue Fract. Eng. Mater. Struct., 1998, vol. 21, pp. 1049-1065.

T. W. Anderson and D. A. Darling, “A test of goodness of fit,” J. Am. Stat. Assoc., 1954, vol. 49, pp. 765-769.

National Institute of Standards and Technology, NIST/SEMATECH e-Handbook of Statistical Methods, 04 2012. http://www.itl.nist.gov/div898/handbook/eda/section3/eda35e.htm. Accessed 30 Apr 2014.

W.S. Rasband, ImageJ and B. M. U. U.S. National Institutes of Health, ImageJ, Image Processing and Analysis in Java, 1997-2014. http://imagej.nih.gov/ij/.

J. O. Andersson, T. Helander, L. Höglund, P. F. Shi and B. Sundman, Calphad, 2002, vol. 26, pp. 273-312.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted on August 26, 2015.

Rights and permissions

About this article

Cite this article

Castro-Cedeño, EI., Herrera-Trejo, M., Castro-Román, M. et al. Evaluation of Steel Cleanliness in a Steel Deoxidized Using Al. Metall Mater Trans B 47, 1613–1625 (2016). https://doi.org/10.1007/s11663-016-0640-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0640-y