Abstract

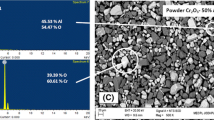

Recycling of aircraft aluminum alloys can be complex due to the presence of their corrosion protection coating that includes inorganic compounds containing Cr(VI). In this study, the characterization and thermal degradation behavior of the coating on aluminum substrates coming from an aircraft destined for recycling are presented. Elements such as Sr, Cr, Si, Ba, Ti, S, C, and O were found in three different layers by EDS elemental mapping corresponding to SrCrO4, Rutile-TiO2, SiO2, and BaSO4 with an overall particle size D 50 = 1.96 µm. The thermal degradation profile analyzed by TGA showed four different stages. The temperature of complete degradation at the fourth stage occurred at 753.15 K (480 °C) at lower heating rates. At higher heating rates and holding an isotherm at the same temperature, the residence time to fully decompose the aircraft coating has been estimated as 4.0 ± 0.2 minutes. The activation energy calculated by the Flynn–Wall–Ozawa and the modified Coats-Redfern methods for multiple fraction of decomposition showed a non-constant behavior indicating the complexity of the reaction. Finally, the concentration of Cr(VI) released to the environment during thermal decoating was obtained by UV–Vis spectroscopy. It was found that 2.6 ± 0.1 µg of Cr(VI)/mm2 of aluminum substrate could be released unless adequate particle controls are used.

Similar content being viewed by others

Notes

The crystalline phases were identified using the JCPDS cards 00-004-0787, 00-021-1276, 00-035-0743, and 01- 085-0457 from the PANanalytical X'pert high-score plus ICDD PDF 2003 database.

References

U.S. Geological Survey, Mineral Commodity Summaries 2012: U.S. Geological Survey. 198, Reston, Virgina, 2012.

2. Das, S.K. and W. Yin, JOM, 2007. Vol. 59(11): p. 57-63.

J.A.S. Green: Aluminum Recycling and Processing for Energy Conservation and Sustainability. 1-271, ASM International, Materials Park, 2007.

M. Nancy: Energy and Environmental Profile of the U.S. Aluminum Industry, Prepared for the U.S. Department of Energy Office of Industrial Technologies. Energetics, INC., Columbia, Maryland, 1997.

5. Kvithyld, A., Meskers, C. E. M., Gaal, S., Reuter, M., Engh, T., JOM, 2008. Vol. 60(8): p. 47-51.

6. Schlesinger, M.E., Ilegbusi, O.J., Iguchi, M., Wahnsiedler, W., Aluminum Recycling. CRC PressINC, United States, 2007.

7. Meskers, C.E.M., Reuter, M. A., Boin, U., Kvithyld, A., Metall. Mater. Trans. B, 2008. Vol. 39(3): p. 500-517.

A. Kvithyld, S. Gaal, P. Kowalewski, and T.A. Engh: TMS Annual Meeting & Exhibition, 2003, pp. 1091–95.

A. Kvithyld, T.A. Engh, and R. Illes: TMS Annual Meeting & Exhibition, 2002, pp. 1055–60.

A. Kvithyld, J. Kaczorowski, and T.A. Engh, TMS Annual Meeting & Exhibition, 2004, pp. 151–56.

X. Zuo and L. Zhang: TMS Annual Meting & Exhibition, 2008, pp. 1107–12.

Z. Itzkowitch: 1ere PIateforme europeenne de demantelement aeronautique, Dossier de presse Bartin AERO Recycling, 2008.

13. Asmatulu, E., M. Overcash, and J. Twomey, J. Ind. Eng., 2013. Vol. 2013: p. 1-8.

14. Chattopadhyay, A.K. and M.R. Zentner, Aerospace and aircraft coatings. Federation of Societies for Coatings Technology, Philadelphia, PA, 1990.

15. Lytle, F.W., Greegor, R. B., Bibbins, G. L., Blohowiak, K. Y., Smith, R. E., Tuss, G. D., Corros. Sci., 1995. Vol. 37(3): p. 349-369.

16. Yu, Z., Ni, H., Zhang, G., Wang, Y., Dong, S., Zhao, G., Appl. Surf. Sci., 1992. Vol. 62(4): p. 217-221.

17. Sinko, J., Prog. Org. Coat., 2001. Vol. 42(3–4): p. 267-282.

18. Bierwagen, G.P. and D.E. Tallman, Prog. Org. Coat., 2001. Vol. 41(4): p. 201-216.

19. LaPuma, P.T., Fox, J. M., Kimmel, E. C., Regul. Toxicol. Pharm., 2001. Vol. 33(3): p. 343-349.

Occupational Safety and health administration (OSHA), Standard—29 CFR number 1910.1026, Cr(VI).

21. Farrier, L.M. and S.L. Szaruga, Mater. Charact., 2005. Vol. 55(3): p. 179-189.

22. Bauer, J.P. and E.N. Ruddy, Metal finishing, 1996. Vol. 94(4): p. 28-39.

23. Köhler, K., Simmendinger, P., Roelle, W., Scholz, W., Valet, A., Slongo, M., Paints and Coatings, 4. Pigments, Extenders, and Additives. Wiley-VCH Verlag GmbH & Co. KGaA, 2000.

24. Scholes, F.H., Furman, S. A., Hughes, A. E., Nikpour, T., Wright, N., Curtis, P. R., Macrae, C. M., Intem, S., Hill, A. J., Prog. Org. Coat., 2006. Vol. 56(1): p. 23-32.

Pashaei, S., Siddaramaiah, A., and A.A. Syed, J. Macromol. Sci., Part A: Pure Appl.Chem., 2010. Vol. 47(8): p. 777-783

26. Petrović, Z.S., Zavargo, Z., Flyn, J.H., Macknight, W. J., J. Appl. Polym. Sci., 1994. Vol. 51(6): p. 1087-1095.

27. Zhang, Y., Xia, Z., Huang, H., Chen, H., J. Anal. Appl. Pyrolysis, 2009. Vol. 84(1): p. 89-94.

28. Di Nola, G., W. de Jong, and H. Spliethoff, Fuel Process. Technol., 2010. Vol. 91(1): p. 103-115.

29. Vamvuka, D., Kakaras, E., Kastanaki, E., Grammelis, P., Fuel, 2003. Vol. 82(15–17): p. 1949-1960.

30. Vyazovkin, S., Burnham, A. K., Criado, J. M., Pérez-Maqueda, L. A., Popescu, C., Sbirrazzuoli, N., Thermochim. Acta, 2011. Vol. 520(1–2): p. 1-19.

31. Flynn, J.H. and L.A. Wall, J Res Nat Bur Stand, 1966. Vol. 70(6): p. 487-523.

32. Ozawa, T., Bull. Chem. Soc. Jpn., 1965. Vol. 38(11): p. 1881-1886.

33. Burnham, A.K. and R.L. Braun, Energy & Fuels, 1998. Vol. 13(1): p. 1-22.

34. Brown, M.E., et al., Thermochim. Acta, 2000. Vol. 355(1–2): p. 125-143.

35. Prosek, T. and D. Thierry, Prog. Org. Coat., 2004. Vol. 49(3): p. 209-217.

36. Furman, S.A., Scholes, F.H., Hughes, A.E. Jamieson, D.N., Macrae, C.M., Glenn, A.M., Corros. Sci., 2006. Vol. 48(7): p. 1827-1847.

37. Burgio, L. and R.J.H. Clark, Spectrochim. Acta, Part A, 2001. Vol. 57(7): p. 1491-1521.

38. Mammone, J.F., Sharma, S. K., Nicol, M., Solid State Commun., 1980. Vol. 34(10): p. 799-802.

Lvov BV and VL Ugolkov (2004) Thermochim. Acta. 411(1):73-79.

Stacey J.S., Stevens R., Liu S., Li G., Navrotsky A., Boerio G.J., WoodfieldBrian F., Am. Mineral., 2009. Vol. 94(2-3): p. 236-243

41. Kotsis, I. and A. Balogh, Ceram. Int., 1989. Vol. 15(2): p. 79-85.

V.T. Athavale and S.K.K. Jatkar: J. Indian Inst. Sci., 1938. vol. 21.

Acknowledgments

The authors would like to thank the Consortium de Recherche et d’Innovation en Aérospatiale au Québec (CRIAQ), Bombardier, Bell Helicopter, Sotrem-Maltech, BFI, Nano Quebec, and Aluminerie Alouette for their project founding, as well as the Secretary of Public Education of México for the complementary scholarship awarded to one of the authors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 21, 2014.

Rights and permissions

About this article

Cite this article

Muñiz Lerma, J.A., Jung, IH. & Brochu, M. Thermal Decoating of Aerospace Aluminum Alloys for Aircraft Recycling. Metall Mater Trans B 47, 1976–1985 (2016). https://doi.org/10.1007/s11663-016-0629-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0629-6