Abstract

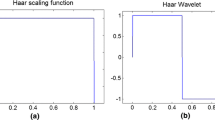

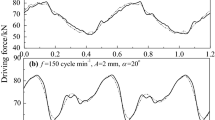

By studying mold friction (MDF), we observed that monitoring and controlling of the friction between the strand and the mold is very important for continuous casting to improve lubrication and prevent breakout. However, existing analysis technologies of MDF do not support the continuous casting very well. In addition, we found that the wavelet entropy has multiscale and statistical properties. Informed by these observations, in this article, we use wavelet entropy to judge the lubrication state between the strand and the mold. First, we demonstrate the implementation and superiority of wavelet entropy and how it helps in efficient evaluation of the lubrication state in mold. A study of wavelet entropy of MDF, which is obtained from the abnormal continuous casting production, such as level fluctuation, submerged entry nozzle broken, and breakout, has been performed to achieve relevant conclusions. The results indicate that the information of MDF in time and frequency domains could be obtained simultaneously by the application of wavelet entropy and that the wavelet entropy has a good sensibility for the study of disorder of MDF, which could further reveal the nature of MDF.

Similar content being viewed by others

References

M. Yao and D. Fang: Ironmaking Steelmaking, 1996, vol. 23, pp. 522-7.

J. Watzinger and A. Flick: Strand Casting Session, 2000, vol. 6, pp. 17-23.

J. Watzinger, A. Pesek, N. Huebner, M. Pillwax, and O. Lang: Ironmaking Steelmaking, 2005, vol. 32, pp. 208-12.

C. Carlos, C. Constantino, C. Angel, B. Manuel, and F. Luis: Iron Steel Technology, 2006, vol. 3, pp. 41-4.

M.R. Ozgu: Can. Metall. Q., 1996, vol. 35, pp. 199-223.

G.A. de Toledo, J. Ciriza, and J.J. Laraudogoitia: Ironmaking Steelmaking, 2003, vol. 30, pp. 353-9.

M. Yong, W. Xudong, Z. Xinyang, Y. Man, Z. Li, and Y. Shihong: Steel Res. Int., 2009, vol. 80, pp. 140, 234.

F. Al-Badour, M. Sunar, and L. Cheded: Mech. Syst. Signal Process., 2011, vol. 25, pp. 2083–101.

H. Zhengyou, G. Shibin, C. Xiaoqin, Z. Jun, B. Zhiqiao, and Q. Qingquan: Elec. Power Energy Syst., 2011, vol. 33, pp. 402–10.

W. Changgang, W. Linchuan, L. Jia, and L. Bin: Appl. Mech. Mater., 2014, vol. 448–453, pp. 2254–2258.

H.H. Bafroui and A. Ohadi: Neurocomputing, 2014, vol. 133, pp. 437-45.

M. Sharanreddy and P.K. Kulkarni: J. Med. Eng. Technol., 2013, vol. 37, pp. 511-9.

N. Qin, W. Jin, J. Huang, P. Jiang, and Z, Li: Adv. Mater. Res., 2013, pp. 753–55, 2286–89.

S. Mallat: IEEE Trans on PA-MI, 1987, vol. 11, p. 674.

O.A. Rosson, S. Blanco, and J. Yordanova, et al.: J. Neurosci. Meth., 2001, vol. 105, pp. 65-75.

P. Xu, X. Hu, and D. Yao: Comput. Biol. Med., 2013, vol. 43, pp. 425-33.

H. Zhengyou, L. Zhigang, and Q. Qingquan: Power Syst. Tech., 2004, vol. 28, pp. 16-8.

Y. Wenxian and J. Jiesheng: Chin. J. Mech. Eng., 2000, vol. 105, pp. 9-13.

H. Zhengyou, C. Yumei, and Q. Qingquan: Proceedings CSEE, 2005, vol. 25, pp. 39-43.

Acknowledgments

The project was supported by NSFC No. 51204063 and AHNSF NO. 1308085QE72.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 20, 2015.

Rights and permissions

About this article

Cite this article

Yong, M., Fangyin, W., Cheng, P. et al. Analysis of Mold Friction in a Continuous Casting Using Wavelet Entropy. Metall Mater Trans B 47, 1565–1572 (2016). https://doi.org/10.1007/s11663-016-0614-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0614-0