Abstract

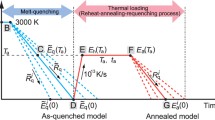

In planar-flow melt spinning, liquid metal is rapidly solidified, against a heat-sink wheel, into thin ribbons which adhere to the substrate wheel. In the absence of a blade to mechanically scrape the ribbon off the wheel, it may wrap fully around and re-enter the solidification region, called ‘catastrophic’ adhesion. Otherwise, detachment occurs part way around the wheel, called ‘natural’ detachment. Natural detachment occurs through a release of thermo-elastic stress after sufficient cooling of the ribbon, according to prior studies. This note extends prior work by invoking a crack propagation view of natural detachment which, when combined with a simple model of the thermo-elastic stress build-up and ribbon cooling, yields an adhesion/detachment criterion characterized by an interfacial adhesion/fracture energy \(\gamma \). For aluminum-silicon alloys frozen against a copper substrate, we report \(\gamma \approx\,\)60 N/m. The criterion can be used to predict detachment once a heat-transfer coefficient is known. We obtain this parameter from natural detachment experiments and then use it to predict catastrophic adhesion in a semi-empirical way. Our note puts a quantitative foundation underneath prior qualitative discussions in the literature. Alternatively, it demonstrates how the interfacial strength of adhesion, a property only of the pair of adhering materials, might be measured based on sticking distance experiments.

Similar content being viewed by others

References

M.C. Narasimhan: US Patent 4142571, 1979.

H.H. Liebermann, Metall. Trans. B 15B, 155–61 (1984)

R. Hasegawa, D. Azuma, Impacts of amorphous metal-based transformers on energy efficiency and environment. J. Magn. Magn. Mater. 320(20), 2451–56 (2008)

D.J. Branagan, B.E. Meacham, and A.V. Sergueeva: US Patent 8317949 B2, 2012.

D.J. Branagan, B.E. Meacham, and A.V. Sergueeva: US Patent 20120263621 A1, 2012.

Deren Li, Jianhong Zhuang, Tiancheng Liu, Shaoxiong Zhou, The pressure loss and ribbon thickness prediction in gap controlled planar-flow casting process. J. Mater. Process. Technol. 211(11), 1764–67 (2011)

H. Sakamoto, T. Yamada, N. Okumura, T. Sato, Improvement in brittleness of amorphous Fe-Si-B-C alloy ribbons by controlling casting conditions. Mater. Sci. Eng. A 206(1), 150–53 (1996)

R.E. Maringer, Solidification on a substrate. Mater. Sci. Eng. 98, 13–20 (1988)

P. Cremer, J. Bigot, An infrared thermography study of the temperature variation of an amorphous ribbon during production by planar flow casting. Mater. Sci. Eng. 98, 95–97 (1988)

A.S. Lavine, F.P. Incropera, D.P. De Witt, Fundamentals of Heat and Mass Transfer (Wiley, New York, 2006)

A.A. Griffith: Philos. Trans. R. Soc. Lond. 221:163–98, 1921.

K. Kendall, Thin-film peeling-the elastic term. J. Phys. D 8(13), 1449 (1975)

B.N.J. Persson, E. Tosatti, The effect of surface roughness on the adhesion of elastic solids. J. Chem. Phys. 115, 5597–10 (2001)

J.K. Carpenter, P.H. Steen, Heat transfer and solidification in planar-flow melt-spinning: high wheelspeeds. Int. J. Heat Mass Transf. 40(9), 1993–2007 (1997)

S.C. Huang: Proc. 4th Int. Conf. on Rapidly Quenched Metals. The Japan Institute of Metals, Sendai, 1981, pp. 65–68.

E.A. Theisen, M.J. Davis, S.J. Weinstein, P.H. Steen, Transient behavior of the planar-flow melt spinning process. Chem. Eng. Sci. 65(10), 3249–59 (2010)

Acknowledgments

The authors thank Brian Carroll and Brenton Cox for their work in capturing/analyzing high-speed video and in interpreting the data. We thank Thomas Ober and Cormac Byrne for starting this project. We also thank Chris Jakobson and Michael Davis for their experimental contributions to this project and also Eric Theisen (Metglas) and Professor C. Y. Hui (Cornell University) for useful discussions. Experiments were supported by NSF Grant No. CMMI-0423791 and CMMI-0726813. We thank ALCOA for supplying materials for these experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 4, 2013.

Rights and permissions

About this article

Cite this article

Altieri, A.L., Steen, P.H. Adhesion Upon Solidification and Detachment in the Melt Spinning of Metals. Metall Mater Trans B 45, 2262–2268 (2014). https://doi.org/10.1007/s11663-014-0128-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-014-0128-6