Abstract

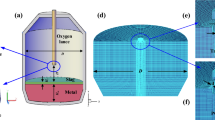

The basic oxygen furnace (BOF) smelting process consists of different chemical reactions among oxygen, slag, and molten steel, which engenders a vigorous stirring process to promote slagging, dephosphorization, decarbonization, heating of molten steel, and homogenization of steel composition and temperature. Therefore, the oxygen flow rate, lance height, and slag thickness vary during the smelting process. This simulation demonstrated a three-dimensional mathematical model for a 100 t converter applying four-hole supersonic oxygen lance and simulated the effect of oxygen flow rate, lance height, and slag thickness on the flow of molten bath. It is found that as the oxygen flow rate increases, the impact area and depth increases, which increases the flow speed in the molten bath and decreases the area of dead zone. Low oxygen lance height benefits the increase of impact depth and accelerates the flow speed of liquid steel on the surface of the bath, while high oxygen lance height benefits the increase of impact area, thereafter enhances the uniform distribution of radial velocity in the molten steel and increases the flow velocity of molten steel at the bottom of furnace hearth. As the slag thickness increases, the diameter of impinging cavity on the slag and steel surface decreases. The radial velocity of liquid steel in the molten bath is well distributed when the jet flow impact on the slag layer increases.

Similar content being viewed by others

References

K.I. Naito, Y. Ogawa, T. Inomoto, S. Kitamura, and M. Yano: ISIJ Int., 2000, vol. 40, pp. 23-30.

B. Deo, A. Krarmcheti, A. Paul, P. Singh, and R.P. Chhabra: ISIJ Int., 1996, vol. 36, pp. 658-66.

Z.F. Yuan, X. Yang, Z.X. Lu, J.N. Huang, Y.F. Pan, and E.X. Ma: J. Iron Steel Res. Int., 2007, vol. 14, pp. 1-5.

Y. Higuchi and Y. Tago: ISIJ Int., 2003, vol. 43, pp. 1410-14.

R. Sambasivam, S.N. Lenka, F. Durst, M. Bock, S. Chandra, and S.K. Ajmani: Metall. Mater. Trans. B, 2007, vol. 38B, pp. 45-53.

Y. Higuchi and Y. Tago: ISIJ Int., 2001, vol. 41, pp. 1454-59.

D.Y. Medina, M.A. Barron, and I. Hilerio: ASME International Mechanical Engineering Congress and Exposition, Seattle, WA, 2007.

M.A. Barron, D.Y. Medina, and I. Hilerio: 2009 International Conference on Modeling, Simulation & Visualization Methods, Las Vegas, NV, 2009.

N. Asahara, K.I. Naito, I. Kitagawa, M. Matsuo, M. Kumakura, and M. Iwasaki: Steel Res. Int., 2011, vol. 82, pp. 587-94.

W.J. Wang, Z.F. Yuan, H. Matsuura, H.X. Zhao, C. Dai, and F. Tsukihashi: ISIJ Int., 2010, vol. 50, pp. 491-500.

H.J. Odenthal, U. Falkenreck, and J. Schlüter: ECCOMAS CFD 2006, Egmond aan Zee, The Netherlands, 2006.

H.J. Odenthal, W.H. Emling, J. Kempken, and J. Schlüter: AISTech 2007 Proceedings, Indianapolis, IN, 2007.

T. Kumagai and M. Iguchi: ISIJ Int., 2001, vol. 41, pp. S52-S55.

K.C. Chou, U.B. Pal, and R.G. Reddy: ISIJ Int., 1993, vol. 33, pp. 862-68.

N. Dogan, G.A. Brooks, and M.A. Rhamdhani: ISIJ Int., 2001, vol. 51, pp. 1102-09.

S.M. Jung and R.J. Fruehan: ISIJ Int., 2000, vol. 40, pp. 348-55.

D. Lotun and L. Pilon: ISIJ Int., 2005, vol. 45, pp. 835-40.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 31, 2012.

Rights and permissions

About this article

Cite this article

Lv, M., Zhu, R., Guo, YG. et al. Simulation of Flow Fluid in the BOF Steelmaking Process. Metall Mater Trans B 44, 1560–1571 (2013). https://doi.org/10.1007/s11663-013-9935-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-013-9935-4