Abstract

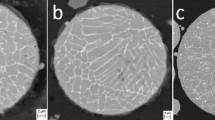

Al-4 wt pct Cu alloy has been gas atomized using a commercial close-coupled gas-atomization system. The resulting metal powders have been sieved into six size fractions, and the SDAS has been determined using electron microscopy. Cooling rates for the powders have been estimated using a range of published conversion factors for Al-Cu alloy, with reasonable agreement being found between sources. We find that cooling rates are very low relative to those often quoted for gas-atomized powders, of the order of 104 K s−1 for sub-38 µm powders. We believe that a number of numerical studies of gas atomization have overestimated the cooling rate during solidification, probably as a consequence of overestimating the differential velocity between the gas and the particles. From the cooling rates measured in the current study, we estimate that such velocities are unlikely to exceed 20 m s−1.

Similar content being viewed by others

References

B. Li, X. Liang, J.C. Earthman and E.J. Lavernia: Acta Mater., 1996, vol. 44, pp. 2409–2420.

M. Kearns: Mater. Sci. Eng. A, 2007, vol. 375-377, pp. 120-126.

O.P. Pandey, N.S. Mishra, C. Ramachandra, S. Lele and S.N. Ojha: Metall. Mater. Trans. A, 1994, vol. 25, pp. 2517-2523.

N. Zeoli, S. Gu and S. Kamnis: Int. J. Heat. Mass. Transf., 2008, vol. 51, pp. 4121–4131.

P. Shukla, R.K. Mandal and S.N. Ojha: Bull. Mater. Sci., 2001, vol. 24, pp. 547–554.

S. He, Y. Liu, and S Guo: Rare Met. Mater. Eng., 2009, vol. 38, pp. 353–56.

J. Kellie: in Cooling Rate and Structure of Commercial Aluminium Alloys in Solidification and Casting, K. O’Reilly and B. Cantor, eds., Taylor & Francis, London, 2002, pp. 271–85.

J. Szekely and N.J. Themelis: Rate phenomena in process metallurgy, 1972, Wiley Interscience, New York.

T.Z. Kattamis, J.C. Coughin, and M.C. Flemings: Trans. Metall. Soc. AIME, 1967, vol. 239, pp. 1504.

K.P. Young and D.H. Kirkwood: Metall. Trans. A, 1975, vol. 6, pp. 197-205.

D.H. Kirkwood: Mater. Sci. Engng, 1985, vol. 73, pp. L1-L4.

A.M. Mullis: Acta Mater., 1998, vol. 46, pp. 4609-4615.

T.F. Bower, H.D. Brody, and M.C. Flemings: Trans. Metall. Soc. AIME, 1966, vol. 236, pp. 624.

J.A. Horwath and L.F. Mondolfo: Acta Metall., 1962, vol. 10, pp. 1037-1043.

J.A. Sarreal and G.J. Abbaschian: Metall. Trans. A, 1986, vol. 17A, 2063–73.

M.A. Talamantes-Silva, A. Rodríguez, J. Talamantes-Silva, S. Valtierra and R. Colás: Mater Charact., 2008, vol. 59, pp. 1434–1439.

D. Eskin, Q. Du, D. Ruvalcaba and L. Katgerman: Mater. Sci. Eng. A, 2005, vol. 405, pp. 1–10.

G. Kasperovich, T. Volkman, L. Ratke and D. Herlach: Metall. Mater. Trans. A, 2008, vol. 39, pp. 1183-1191.

V. Anand, A.J. Kaufman, and N.J. Grant: in Rapid Solidification Processing, Principles & Technologies II, R. Mehrabian, B.H. Kear, and M. Cohen, eds., Claitor, Baton Rouge, 1978, pp. 273–86.

I.E. Anderson, R.S. Figliola and H. Morton: Mater. Sci. Eng. A, 1991, vol. 148, pp. 101-114.

J. Alkemper, S. Sous, C. Stocker, and L. Ratke: J. Cryst. Growth, 1998, vol. 191, pp. 252–60.

J. Ting, J. Connor and S. Ridder: Mater. Sci. Eng. A, 2005, vol. 390, pp. 452.

A.M. Mullis, N.J. Adkins, Z. Aslam, I.N. McCarthy and R.F. Cochrane: Int. J. of Powder Metall., 2008, vol. 44, pp. 55-64.

A.M. Mullis, I.N. McCarthy and R.F. Cochrane: J. Mater. Process. Technol., 2011, vol. 211, pp. 1471-1477.

R.P. Underhill, P.S. Grant, B. Cantor and D.J. Bryant: Int. J. Nonequilib. Process., 1997, vol. 10, pp. 201–216.

D. Bergmann, U. Fritsching and K. Bauckhage: Int. J. Therm. Sci., 2000, vol. 39, pp. 53–62.

M.M. Tong and D.J. Browne: J. Mater. Process. Tech., 2008, vol. 202, pp. 419–427.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 1, 2013.

Rights and permissions

About this article

Cite this article

Mullis, A.M., Farrell, L., Cochrane, R.F. et al. Estimation of Cooling Rates During Close-Coupled Gas Atomization Using Secondary Dendrite Arm Spacing Measurement. Metall Mater Trans B 44, 992–999 (2013). https://doi.org/10.1007/s11663-013-9856-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-013-9856-2