Abstract

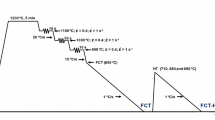

The recently developed application of the MicroNiobium Alloy Approach® in medium- and high-carbon steel long products, sheets, and plate steels enhances both the metallurgical properties and processability, as well as reducing the operational cost per tonne of production. The process and product metallurgy improvements relate to the Nb-pinning effect of the austenite grain boundaries. The metallurgical mechanism of the MicroNiobium Alloy Approach is related to the retardation of austenite grain coarsening during reheat furnace soaking of the billets, slabs, or shapes before rolling. Variable grain size is induced by temperature fluctuations and inhomogeneity during the heating of the slabs in the reheat furnace. Such fluctuations can occur because of variations in the air- to gas-ratio, directly affecting the adiabatic flame temperature and heat input into the slabs. This approach contributes to the achievement of an ultrafine grain, homogeneous higher carbon microstructures that exhibit superior toughness, high strength, less mechanical property variation in the final hot-rolled product, and reduced cost of quality. The reduced cost of quality far exceeds the additional alloy cost for the Nb addition.

Similar content being viewed by others

References

S. Jansto, Nordic Steel and Mining Review, vol. 195, no. 7, 2011, pp. 42-48.

P. Cotterill and P.R. Mould, Recrystallization and Grain Growth in Metals, Surrey University Press, New York, 1976, pp. 266-275.

K.A. Olgab, D.K. Matlock and J.G. Speer: Proc. Conference on New Developments on Metallurgy and Applications Steels, 2008, Tenaris Center for Industrial Research, Buenos Aires.

M. Head, T. King and A. Radulescu, AISI Great Designs in Steel Seminar, 2005, Livonia, Michigan.

J. Speer, D. Matlock and G. Krauss, Materials Science Forum, 2005, vol. 500-501, p.87-96.

Q.Yue and Y. Sun, Materials Science and Engineering A, 2006, vol. 420, pp. 34-38.

S. Jansto, 21 st International Conference on Metals, 2012, Brno, Czech Republic, pp.1-8.

R.J. Reed: North American Combustion Handbook, 2nd ed., 1978, pp. 1–14.

A.K. Gupta and T. Hasegawa: Proceedings Symposium on High Temperature Air Combustion, 1999, pp. 10–28.

A.K. Gupta and Z. Li: Proceedings International Joint Power Generation Conference, 1997, pp. 247–57.

L.Nemethova, Acta Metallurgica Slovaca, 2009, vol. 15, no.3. pp. 173-79.

T. Murakami, H. Hatano, Y. Shindo, M. Nagahama and H. Yaguchi, Materials Science Forum, vol. 539-543, 2007, pp. 4167-72.

S. Kinoshita, T. Ueda and A. Suzuki, Tetsu-to-Hagane, vol. 59, 1973, p.443-50.

S. Fukui and N. Uehara, Denki Seiko, vol. 46, 1975, p. 82-89.

N. Gao and T.N. Baker, ISIJ International, vol. 38, no. 7, 1998, pp. 774-51.

H.Ochiai, Y.Ohba, Y. Hida and M.Nagumo, Tetsu-to- Hagane, vol. 70, 1980, p. 2009-11.

K. Narita, A. Miyamoto, F. Kawaguchi, and S. Nasu: Tetsu- to-Hagane, vol. 47, 1961, p. 1512–18.

A.Adachi, K.Mizukawa and K.Kanda, Tetsu-to-Hagane, Vol. 49, 1963, p. 894-900.

S. Jansto, MS&T Conference Proceedings, Pittsburgh, PA, October 2008, pp.1289-1301.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 22, 2013.

Rights and permissions

About this article

Cite this article

Jansto, S.G. MicroNiobium Alloy Approach in Medium and High Carbon Steel Bar, Plate and Sheet Products. Metall Mater Trans B 45, 438–444 (2014). https://doi.org/10.1007/s11663-013-9837-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-013-9837-5