Abstract

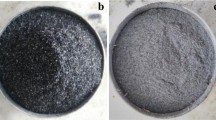

A novel method is adapted to prepare an in situ ceramic composite from waste colliery shale (CS) material. Heat treatment of the shale material, in a plasma reactor and/or in a high temperature furnace at 1673 K (1400 °C) under high vacuum (10−6 Torr), has enabled in situ conversion of SiO2 to SiC in the vicinity of carbon and Al2O3 present in the shale material. The composite has the chemical constituents, SiC-Al2O3-C, as established by XRD/EDX analysis. Particle sizes of the composite range between 50 nm and 200 μm. The shape of the particles vary, presumably rod to spherical shape, distributed preferably in the region of grain boundaries. The CS composite so produced is added to aluminum melt to produce Al-CS composite (12 vol. pct). For comparison of properties, the aluminum metal matrix composite (AMCs) is made with Al2O3 particulates (15 vol. pct) with size <200 μm. The heat-treated Al-CS composite has shown better mechanical properties compared to the Al-Al2O3 composite. The ductility and toughness of the Al-CS composite are greater than that of the Al-Al2O3 composite. Fractographs revealed fine sheared dimples in the Al-CS composite, whereas the same of the Al-Al2O3 composite showed an appearance of cleavage-type facets. Abrasion and frictional behavior of both the composites have been compared. The findings lead to the conclusion that the in situ composite developed from the colliery shale waste material has a good future for its use in AMCs.

Similar content being viewed by others

References

D.B. Miracle: Compo. Sci. Tech., 2005, vol. 65, pp. 2526-40.

C. Lane and M. Lenox: Proc. of the 2nd Inter. Conf. on Cast Metal Matrix Composites, Tuscaloosa, 1993, pp. 253–62.

W.H. Hunt and D.B Miracle: ASM Handbook, 2001, vol. 21, pp. 1029–32.

D. Lloyd: Int. Mater. Rev., 1999, vol.39, pp. 1-23.

D.R. Herling, G. Grant, and W. Hunt: Adv. Mater. Process, 2001, vol.159, pp. 37-43.

R.J. Arsenault and N. Shi: Mater. Sci. Eng., 1986, vol. 81, pp. 175-78.

N. Shi and R. J. Arsenault: J. of comp. Tech. and Res., 1991, vol.13, pp. 211-26.

N. Shi and R. J. Arsenault: Metall. Trans. A, 1993, vol. 24A, pp. 1879-82.

M. Kouzeli, L. Weber, C. San Marchi, A. Mortensen: Acta Metall., 2001, vol. 49, pp. 3699-709.

J.E. Spowart and D.B. Miracle: Mater. Sci. Eng. A, 2003, vol.357, pp. 111-23.

J.J. Lewandowski and C. Liu: Mater. Sci. Eng. A, 1989, vol.107, pp. 241-55.

V.V. Bhanu Prasad, B.V.R. Bhat, Y.P. Mahajan, and P. Ramakrishnan: Mater. Sci. Eng. A, 2002, vol. 337, pp. 179–86.

M. Kouzeli, and D.C. Dunand: Acta Metall., 2003, vol. 51, pp. 6105-21.

DB. Miracle: Compo. Sci. Tech., 2005, vol. 65, pp. 2526-40.

M.K. Surappa: Sadhana, 2003, vol. 28, pp. 319-34.

J.E. Allison and G.S. Cole: JOM, 1993, vol.45, pp. 19-24.

R.J. Lederich and S.M.L. Sastry: Mater. Sci. Eng., 1982, vol. 55, pp. 143-46.

M. Single, D. Dwivedi, L. Singh, and V. Chawla: J. Min. Mater. Charact. Eng., 2009, vol. 8, pp. 455–67.

P. Poddar, S. Mukherjee, and K.L. Sahoo: J. Mater. Eng. Perform., 2009, vol. 18, pp. 849- 55.

J. Hashim, L. Looney, and M.S.J. Hashmi: J. Mater. Pro. Tech., 2001, vol. 119, pp. 329-335.

J. Hashim, L. Looney, and M.S.J. Hashmi: J. Mater. Pro. Tech., 2001, vol. 119, pp. 324-328.

S.K Singh, B.C Mohanty, and S. Basu: Bull: Mater. Sci., 2002, vol. 25, pp. 561-63.

S.B. Venkata Siva, K.L. Sahoo, R.I. Ganguly, and R.R. Dash: J. Mater. Eng. Perform., 2012, vol. 21, pp. 1226–31.

L. Ceschini, G. Minak, and A. Morri: Compos. Sci. Technol., 2009, vol. 69, pp. 1783–89.

P. Cavaliere and E. Evangelista: Compos. Sci. Technol., 2006, vol. 66, pp. 357–62.

S. Das, R. Behera, A. Datta, G. Majumdar, B. Oraon, and G. Sutradhar: Mater. Sci. Appli., 2010, vol. 1, pp. 310-16.

K. H. Im and C. K. H. Dharan: Inter. J. Machine Tools Manuf., 1997, vol. 37, pp. 1281-302.

M. Vedani, F.D’Errico, and E. Gariboldi: Scripta Metall. Mater. 1995, vol. 33, pp. 857–62.

K.L. Sahoo, C.S.S. Krishna, and A.K. Chakrabarti: Wear, 2000, vol. 239, pp. 211-18.

M. Singla, L. Singh, and V. Chawla: J. Min. Mater. Charat. Eng. 2009, vol. 8, pp. 813–19.

A. Vencl, A. Rac, I. Bobic, and Z. Miskovic: Tribol. Indus. 2006, vol. 28, pp. 27–31.

A. Vencl, A. Rac, and I. Bobic: Tribol. Indus., 2004, vol. 26, pp. 31–38.

A.D. Wilson, E.G. Hamburg, D.J. Colvin, S.W. Thompson, and G. Krauss: Proceedings on Conference on Micro Alloyed HSLA stu, ASM, Chicago, 1988, p. 259.

M. Roy, B. Venkataraman, V.V. Bhanuprasad, Y.R. Mahajan, and G. Sundararajan: Metall. Trans. A, 1992, vol. 23, pp. 2833-47.

F.M Hosling, F.F. Poryillo, R. Wunderlin, and R. Mehrabian: J. Mater. Sci., 1982, vol. 17, pp. 477-98.

A. Sato and R. Mehrabian: Metall. Trans. B, 1976, vol. 7, pp. 443-51.

Acknowledgments

The authors acknowledge the M/S National Aluminium Ltd. Company, Bhubaneswar, India, for providing the aluminum and necessary funds for carrying out the investigation. The authors are, in particular, grateful to the Gandhi Institute of Engineering and Technology for permitting the research in the Laboratory and as well as providing permission for publishing the work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 27, 2011.

Rights and permissions

About this article

Cite this article

Venkata Siva, S.B., Sahoo, K.L., Ganguly, R.I. et al. Preparation of Aluminum Metal Matrix Composite with Novel In situ Ceramic Composite Particulates, Developed from Waste Colliery Shale Material. Metall Mater Trans B 44, 800–808 (2013). https://doi.org/10.1007/s11663-013-9832-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-013-9832-x