Abstract

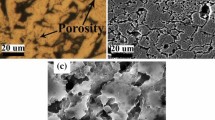

The effects of process parameters on the microstructure, microhardness, and dry-sliding wear behavior of plasma nitrided 17-4PH stainless steel were investigated by X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and wear testing. The results show that a wear-resistant nitrided layer was formed on the surface of direct current plasma nitrided 17-4PH martensitic stainless steel. The microstructure and thickness of the nitrided layer is dependent on the treatment temperature rather than process pressure. XRD indicated that a single α N phase was formed during nitriding at 623 K (350 °C). When the temperature increased, the α N phase disappeared and CrN transformed in the nitrided layer. The hardness measurement demonstrated that the hardness of the stainless substrate steel increased from 320 HV0.1 in the untreated condition increasing to about 1275HV0.1 after nitriding 623 K (350 °C)/600 pa/4 hours. The extremely high values of the microhardness achieved by the great misfit-induced stress fields associated with the plenty of dislocation group and stacking fault. Dry-sliding wear resistance was improved by DC plasma nitriding. The best wear-resistance performance of a nitrided sample was obtained after nitriding at 673 K (350 °C), when the single α N-phase was produced and there were no CrN precipitates in the nitrided layer.

Similar content being viewed by others

References

W. Jui-Hung and L. Chih-Kuang: J. Mater. Sci., 2003, vol. 38, pp. 965-71.

J. Wang, H. Zou, C. Li, S.-Yu. Qiu, and B.-L. Shen: Metall. Trans., 2005, vol. 46, pp. 846–51.

J. Wang, H. Zou, C. Li, Y. Peng, S. Qiu, and B. Shen: J. Mater. Eng. Perform., 2012, vol. 21, pp. 1708–12.

J. Wang, H. Zou, C. Li, S. Qiu, and B. Shen: Mater. Char., 2006, vol. 57, pp. 274-80.

G.-J. Li, J. Wang, Q. Peng, and B. Shen: Nucl. Instr. Meth. B, 2008, vol. 266, pp. 1964–70.

F. Alonso, A. Arizaga, A. Garcia, and J.I. Onate: Surf. Coat. Technol., 1994, vol. 66, pp. 291-5.

M. Esfandiari and H. Dong: Surf. Eng., 2006, vol. 22, pp. 86-92.

C.X. Li and T. Bell: Corros. Sci., 2006, vol. 48, pp. 2036-49.

G.J. Li, J. Wang, Q. Peng, C. Li, Y. Wang, and B.L. Shen: J. Mater. Proc. Technol., 2008, vol. 207, pp. 187-92.

M. Esfandiari and H. Dong: Surf. Coat. Technol., 2007, vol. 202, pp. 466-78.

R.B. Frandsen, T. Christiansen, and M.A.J. Somers: Surf. Coat. Technol., 2006, vol. 200, pp. 5160-9.

D. Manova, G. Thorwarth, S. Mandl, H. Neumann, B. Stritzker, and B. Rauschenbach: Nucl. Instr. Meth. B, 2006, vol. 242, pp. 285-8.

Y. Sun and T. Bell: Surf. Eng., 2003, vol. 19, pp. 331-5.

H. Dong, M. Esfandiari, and X.Y. Li: Surf. Coat. Technol., 2008, vol. 202, pp. 2969-75.

P. Kochmański and J. Nowacki: Surf. Coat. Technol., 2006, vol. 200, pp. 6558-62.

P. Kochmański and J. Nowacki: Surf. Coat. Technol., 2008, vol. 202, pp. 4834-8.

K. Marusic, H. Otmacic, D. Landek, and F. Cajner: Surf. Coat. Technol., 2006, vol. 201, pp. 3415-21.

C. Blawert, A. Weisheit, B.L. Mordike, and R.M. Knoop: Surf. Coat. Technol., 1996, vol. 85, pp.15-27.

B. Larisch, U. Brusky, and H.J. Spies: Surf. Coat. Technol., 1999, vols. 116–119, pp. 205–11.

C.E. Foerster, F.C. Serbena, S.L.R. da Silva, C.M. Lepienski, C.J.d.M. Siqueira, and M. Ueda: Nucl. Instr. Meth. B, 2007, vol. 257, pp. 732–36.

E. Menthe, K.T. Rie, J.W. Schultze, and S. Simson: Surf. Coat. Technol., 1995, vols. 74–75, pp. 412–16.

C.E. Foerster, F.C. Serbena, S.L.R. da Silva, C.M. Lepienski, C.J.d.M. Siqueira, and M. Ueda: Nucl. Instr. Meth. B, 2007, vol. 257, pp. 732–36.

M.P. Fewell, D.R.G. Mitchell, J.M. Priest, K.T. Short, and G.A. Collins: Surf. Coat. Technol., 2000, vol. 131, pp. 300-6.

E. Menthe, U.A. Bulak, J. Olfe, A. Zimmermann, and K.T. Rie: Surf. Coat. Technol., 2000, vols. 133–134, pp. 259–63.

S. Mändl, B. Fritzsche, D. Manova, D. Hirsch, H. Neumann, E. Richter, and B. Rauschenbach: Surf. Coat. Technol., 2005, vol. 195, pp. 258–63.

P. Corengia, G. Ybarra, C. Moina, A. Cabo, and E. Broitman: Surf. Coat. Technol., 2004, vol. 187, pp. 63-9.

R.L. Liu and M.F. Yan: Surf. Coat. Technol., 2010, vol. 205, pp. 345-9.

I. Alphonsa, A. Chainani, P.M. Raole, B. Ganguli, and P.I. John: Surf. Coat. Technol., 2002, vol. 150, pp. 263-8.

C. Reinhard, A.P. Ehiasarian, and P.E. Hovsepian: Thin Solid Films, 2007, vol. 515, pp. 3685-92.

X. Li, M. Samandi, D. Dunne, G. Collins, J. Tendys, K. Short, and R. Hutchings, Surf. Coat. Technol., 1996, vol. 85, pp. 28-36.

X. Xiaolei, W. Liang, Y. Zhiwei, and H. Zukun: Surf. Coat. Technol., 2005, vol. 192, pp. 220-4.

Acknowledgments

The authors are very grateful to the National Natural Science Foundation of China (Grant No. 50901047) for financial support of this research work. J.W. thanks Prof. Luo Defu of Xihua University, China, for his valuable discussions during the course of the research and Prof. Trevor Dean of Birmingham University for his generous revision of the manuscript’s grammar.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 27, 2012.

Rights and permissions

About this article

Cite this article

Wang, J., Lin, Y., Zeng, D. et al. Effects of the Process Parameters on the Microstructure and Properties of Nitrided 17-4PH Stainless Steel. Metall Mater Trans B 44, 414–422 (2013). https://doi.org/10.1007/s11663-012-9781-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-012-9781-9