Abstract

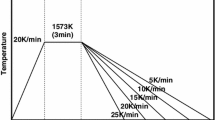

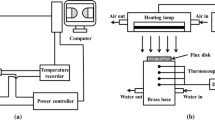

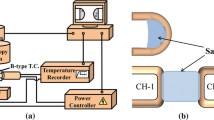

The effect of basicity on the mold fluxes crystallization was investigated in this article. The time-temperature-transformation (TTT) diagrams and continuous-cooling-transformation (CCT) diagrams of mold fluxes with different basicity were constructed by using single, hot thermocouple technology (SHTT). The results showed that with the increase of basicity, the incubation time of isothermal crystallization became shorter, the crystallization temperature was getting higher, and the critical cooling rate of continuous cooling crystallization became faster. The X-ray diffraction analysis suggested that calcium silicate (CaO·SiO2) was precipitated at the upper part of the TTT diagram and cuspidine (Ca4Si2O7F2) was formed at the lower part, when the basicity of mold fluxes was within 1.0 to 1.2. However, when basicity was 0.8, only the cuspidine phase was formed. A kinetic study of isothermal crystallization process indicated that the increase of the basicity tended to enhance the mold flux crystallization, and the crystallization activation energy became smaller. The crystallization mechanism of cupsidine was changing from one-dimensional growth to three-dimensional growth with a constant number of nuclei, when the basicity of mold fluxes varied from 0.8 to 1.2.

Similar content being viewed by others

References

K.C. Mills, A.B. Fox, Z. Li, and R.P. Thackray: Ironmaking Steelmaking, 2005, vol. 32, no. 1, pp. 26-34.

Y. Meng, B.G. Thomas, A.A Polycarpou, H. Henein, and A. Prasad: MS & T 2004 Conf. Proc., New Orlean, LA, AIST, Warrendale, PA, 2004, pp. 57–67.

Y. Kashiwaya, C.E. Cicutti, A.W. Cramb, and K. Ishii: ISIJ Int., 1998, vol. 38, no. 4, pp. 348-56.

C. Orrling and A.W. Cramb: Metall. Mater. Trans. B., 2000, vol. 31B, pp. 403-06.

C. Orrling, S. Sridhar, and A.W. Cramb: High Temp. Mater. Process., 2001, vol. 20, nos. 3-4, pp. 195-200.

T. Watanabe, H. Fukuyama, M. Susa, and K. Nagata: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 1273-81.

M. Hanao, M. Kawamoto, and T. Watanabe: ISIJ Int., 2004, vol. 44, no. 5, pp. 827-35.

Y. Tan and D. Ju: Mater. Sci. Forum, 2011, vols. 675-7, pp. 877-80.

W. Wang, K. Blazek, and A.W. Cramb: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 66-74.

D. Wang, C. Liu, P. Shi, and M. Jiang: J. Iron Steel Res., 2004, vol. 16, no. 5, pp. 28-32.

Z. Li, R. Thackray, and K.C. Mills: VII Int. Conf. on Molten Slags, Fluxes and Slats, The Southern African Institute of Mining and Metallurgy, Marshalltown, South Africa, 2004, pp. 813–20.

H.G. Ryu, Z.T. Zhang, J.W. Cho, G.H. Wen, and S. Sridhar. ISIJ Int., 2010, vol. 50, no. 8, pp. 1142-50.

Z. Zhang, G. Wen, P. Tang, and S. Sridhar: ISIJ Int., 2008, vol. 48, no. 6, pp. 739-46.

P. Tang: Ph.D. Dissertation, Chongqing University, Chongqing, China, 2010.

M. Persson, M. Gornerup, and S. Seetharaman: ISIJ Int., 2007, vol. 47, no. 10, pp. 1533-40.

K.C. Mills: ISIJ Int., 1993, vol. 33, no. 1, pp. 148-55.

N.X. Sun, X.D. Liu, and K. Lu: Scripta Mater., 1996, vol. 34, no. 8, pp. 1201-07.

W. Wang: Ph.D. Dissertation, Carnegie Mellon University, Pittsburgh, PA, 2007.

N. Boonyachut: Ph.D. Dissertation, Carnegie Mellon University, Pittsburgh, PA, 2007.

A.A. Elabbar, M. Abu El-Oyoun, and A.A. Abu-Sehly: JTUSCI, 2008, pp. 44–50.

Y. Kashiwaya, C.E. Cicutti, and A.W. Cramb: ISIJ Int., 1998, vol. 38, no. 4, pp. 357-65.

G. Wen, H. Liu, and P. Tang: J. Iron Steel Res., Int., 2008, vol. 15, no. 4, pp. 32–37.

A.J Moore, R.J. Phillips, and T.R. Gibbs: Steelmaking Conf. Proc., 1991, pp. 615–21.

K.C. Mills, A.B. Fox, P.P. Thackray, and Z. Li: VII International Conference on Molten Slags Fluxes and Salts, The South African Institute of Mining and Metallurgy, 2004, pp. 713–21.

K. Prapakorn: Ph.D. Dissertation, Carnegie Mellon University, Pittsburgh, PA, 2003.

J.W. Christian: The Theory of Transformations in Metals and Alloys. 3rd ed, Pergamon Press Ltd, London, UK, 2002.

D.R. MacFarlane and M. Fragoulis: Phys. Chem. Glasses, 1986, vol. 37, no. 6, pp. 228-34.

Acknowledgments

The work was supported by International Science & Technology Cooperation Program of China (2011DFA71390), New Century Excellent Talents Program Award (Chinese Ministry of Education, NCET-10-0797), and the Fundamental Research Funds for the Central Universities (2011JQ010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 27, 2011.

Rights and permissions

About this article

Cite this article

Zhou, L., Wang, W., Ma, F. et al. A Kinetic Study of the Effect of Basicity on the Mold Fluxes Crystallization. Metall Mater Trans B 43, 354–362 (2012). https://doi.org/10.1007/s11663-011-9591-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-011-9591-5