Abstract

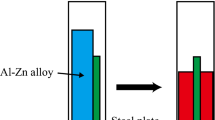

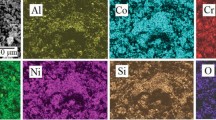

The microstructure and thickness of 55 pct A1-Zn-1.6 pct Si-0.2 pct RE coatings during continuous hot-dip on Q235 steel were investigated in this work. The experimental results revealed that the intermetallic layer was composed of the Fe2Al5, FeAl3, and α-FeAlSi phases. The results of thermodynamic calculations with Pandat software package (CompuTherm, LLC, Madison, WI) indicated that FeAl3 and α(β)-FeAlSi phase precipitated during the period of temperature cooling, which was consistent with experimental result. Then, the thickness of intermetallic layer was characterized. It was shown that the thickness of intermetallic layer decreased after 0.2 wt pct RE was added. Finally, a first-principles calculation was performed to interpret the effect mechanism of RE on the thickness of intermetallic layer. The results indicated that La substitution in Fe2Al5 and FeAl3 phases could grab electronic charges from Al atoms and weaken the formation of Fe-Al compounds.

Similar content being viewed by others

References

A.R. Marder: Prog. Mater. Sci., 2000, vol. 45, no. 3, pp. 191-271.

R. Chen and D. Willis: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 117-28.

D. Yang, J. Chen, Q. Han, and K. Liu: J. Rare Earths, 2009, vol. 27, no. 1, pp. 114-18.

H.F. Li, J.S. Zheng, and D.Y. Yu: J. Huazhong Univ. Sci. Tech., 2003, vol. 35, no. 5, pp. 107-09.

J. Selverian, A. Marder, and M. Notis: Metall. Trans. A, 1988, vol. 19A, pp. 1193-1203.

D. Phelan, B.J. Xu, and R. Dippenaar: Mater. Sci. Eng. A, 2006, vol. 420, no. 1-2, pp. 144-49.

B. Xu, D. Phelan, and R. Dippenaar: Mater. Sci. Eng. A, 2008, vol. 473, no. 1-2, pp. 76-80.

F. García, A. Salinas-Rodriguez, and E. Nava: Mater. Sci. Forum, 2007, vol. 560, pp. 97-102.

J.B. Liu: Hot Dip Aluminumon Steel, Metallurgy Industry Press, Beijing, China, 1995, pp. 105-10.

Y.H. Liu and N.Y. Tang: Computer Modeling of Aluminum Uptake and Iron Dissolution in Galvanizing and Galvannealing 6th International Conference on Zinc and Zinc Alloy Coated Steel Sheet, Galvatech’s 04, Chicago, IL, 2004.

A. Sémoroz, L. Strezov, and M. Rappaz: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 2685-94.

F. Yang, J. Zhang, Q. Li, S. Chen, and G. Zhou: Shanghai Met., 2010, vol. 32, no. 5, pp. 9-13.

Q. Li, Y.-Z. Zhao, Q. Luo, S.-L. Chen, J.-Y. Zhang, and K.-C. Chou: J. Alloys Compd., 2010, vol. 501, no. 2, pp. 282-90.

J. Selverian, M. Notis, and A. Marder: J. Mater. Eng., 1987, vol. 9, no. 2, pp. 133-40.

Y. Han, C. Ban, Q. Ba, S. Guo, S. Wang, and J. Cui: Mater. Lett., 2006, vol. 60, no. 15, pp. 1884-87.

J. Selverian, A. Marder, and M. Notis: Metall. Trans. A, 1989, vol. 20A, pp. 543-55.

W. Cao, S.L. Chen, F. Zhang, K. Wu, Y. Yang, Y.A. Chang, R. Schmid-Fetzer, and W.A. Oates: CALPHAD, 2009, vol. 33, no. 2, pp. 328-42.

M. Rappaz, C.A. Gandin, A.M. Stoneham, M. McLean, and M.S. Loveday: Phil. Trans., 1995, vol. 351, no. 1697, pp. 563-77.

P.J. Spencer: CALPHAD, 2008, vol. 32, no. 1, pp. 1-8.

G. Kresse and J. Furthmuller: Phys. Rev. B, 1996, vol. 54, no. 16, pp. 11169-86.

J.P. Perdew, J.A. Chevary, S.H. Vosko, K.A. Jackson, M.R. Pederson, D.J. Singh, and C. Fiolhais: Phys. Rev. B, 1992, vol. 46 (11), p. 6671.

P. E. Blochl: Phys. Rev. B, 1994, vol. 50, no. 24, pp. 17953-79.

H.J. Monkhorst and J.D. Pack: Phys. Rev. B, 1976, vol. 13, no. 12, pp. 5188-92.

W.H. Press, S.A. Teukolsky, and W.T. Vetterling: Numerical Recipes: The Art of Scientific Computing, Cambridge University Press, New York, NY, 1996, pp. 153-55.

H.M. Jin, Y. Li, H.L. Liu, and P. Wu: Chem. Mater., 2000, vol. 12, no. 7, pp. 1879-83.

P. Wu, H.M. Jin, and H.L. Liu: Chem. Mater., 2002, vol. 14, no. 2, pp. 832-37.

Acknowledgments

The authors would like to acknowledge the financial supports from Chinese National Key Technology R&D Program (2007BAE09B03), National Natural Science Foundation of China (51074103, 51104098), Science and Technology Commission of Shanghai Municipality (09195802700), and Aluminum Corporation of China (Science and Technology Development Fund, 2007KJA07). The authors would like to thank Instrumental Analysis & Research Center of Shanghai University for SEM observations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 25, 2011.

Rights and permissions

About this article

Cite this article

Wu, G., Zhang, J., Li, Q. et al. Microstructure and Thickness of 55 pct Al-Zn-1.6 pct Si-0.2 pct RE Hot-Dip Coatings: Experiment, Thermodynamic, and First-Principles Study. Metall Mater Trans B 43, 198–205 (2012). https://doi.org/10.1007/s11663-011-9578-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-011-9578-2