Abstract

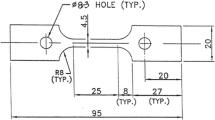

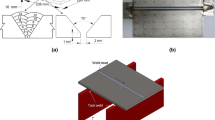

A novel variant of tungsten inert gas (TIG) welding called activated-TIG (A-TIG) welding, which uses a thin layer of activated flux coating applied on the joint area prior to welding, is known to enhance the depth of penetration during autogenous TIG welding and overcomes the limitation associated with TIG welding of modified 9Cr-1Mo steels. Therefore, it is necessary to develop a specific activated flux for enhancing the depth of penetration during autogeneous TIG welding of modified 9Cr-1Mo steel. In the current work, activated flux composition is optimized to achieve 6 mm depth of penetration in single-pass TIG welding at minimum heat input possible. Then square butt weld joints are made for 6-mm-thick and 10-mm-thick plates using the optimized flux. The effect of flux on the microstructure, mechanical properties, and residual stresses of the A-TIG weld joint is studied by comparing it with that of the weld joints made by conventional multipass TIG welding process using matching filler wire. Welded microstructure in the A-TIG weld joint is coarser because of the higher peak temperature in A-TIG welding process compared with that of multipass TIG weld joint made by a conventional TIG welding process. Transverse strength properties of the modified 9Cr-1Mo steel weld produced by A-TIG welding exceeded the minimum specified strength values of the base materials. The average toughness values of A-TIG weld joints are lower compared with that of the base metal and multipass weld joints due to the presence of δ-ferrite and inclusions in the weld metal caused by the flux. Compressive residual stresses are observed in the fusion zone of A-TIG weld joint, whereas tensile residual stresses are observed in the multipass TIG weld joint.

Similar content being viewed by others

References

W.B. Jones, C.R. Hills, and D.H. Polonis: Metall. Trans. A, 1991, vol. 22A, pp. 1049-58.

S. Spigraelli, E. Cerri, P. Bianchi, and E. Evangelista: Mater. Sci. Technol., 1999, vol. 15, pp. 1433-40.

S.L. Mannan, S.C. Chetal, R. Baldev, and S.B. Bhoje: Trans. Indian Inst. Met., 2003, vol. 56, no. 2, pp. 155-78.

E.L. Bergquist: Consumables and Welding Modified 9cr-1Mo Steel, ESAB AB, Goteborg, Sweden, Svetsaren, 1999, vols. 1–2, pp. 22–25.

R. Badev, S.L. Mannan, P.R. Vasudeva Rao, and M.D. Mathew: Sadhana, 2002, vol. 27, no. 5, pp. 527-58.

M. Vasudevan: Ph.D. Dissertation, Indian Institute of Technology, Chennai, India, 2007.

M. Vasudevan, A.K. Bhaduri, and R. Baldev: Development and Evaluation of Activated Flux for TIG Welding of Type 304LN and Type 316LN Stainless Steels, International Institute of Welding International Congress, Chennai, India, 2008, pp. 211–18.

M. Marya: Int. J. Mech. Mater. Eng., 2006, vol. 1, no. 1, pp. 1-10.

J.J. Lowke, M. Tanaka, and M. Ushio: J. Phys. D: Appl. Phys., 2005, vol. 38, pp. 3438-45.

M. Tanaka, T. Shimizu, H. Terasaki, M. Ushio, F. Koshi-ishi, and C.L. Yang: Sci. Tech. Weld. Joi., 2000, vol. 5, no. 6, pp. 397-402.

K.H. Tseng and C.Y. Hsu: J. Mater. Process. Tech., 2011, vol. 211, pp. 503-12.

T. Paskell, C. Lundin, and H. Castner: Weld. J., 1997, vol. 76, no. 4, pp. 57-62.

S. Leconte, P. Paillard, and J. Saindrenan: Sci. Tech. Weld. Joi., 2006, vol. 11, no. 1, pp. 43-47.

P.J. Modenesi, E.R. Apolina′rio, and I.M. Pereira: J. Mater. Process. Tech., 2000, vol. 99, nos. 1-3, pp. 260-65.

M. Marya and G.R. Edwards: Weld. J., 2002, vol. 81, no. 12. pp. 291-98.

P.J. Withers and H.K.D.H. Bhadeshia: Mater. Sci. Technol., 2001, vol. 17, pp. 355-65.

S.P. Lu, H. Fujii, M. Tanaka, and K. Nogi: Trans. WRI, 2004, vol. 33, no. 3, pp. 5-9.

S.P. Lu, H. Fujii, and K. Nogi: Mater. Sci. Eng. A, 2004, vol. 380, pp. 290-97.

V. Kumar, B. Lucas, D. Howse, G. Melton, S. Raghunathan, and L. Vilarinho: 15th Int. Conf. on the Joining of Materials (JOM 15) and 6th Int. Conf. on Education in Welding (ICEW 6), Helsinger, Denmark, 2009.

D. Deng and H. Murakawa: Comput. Mater. Sci., 2006, vol. 37, pp. 209-19.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 7, 2011.

Rights and permissions

About this article

Cite this article

Maduraimuthu, V., Vasudevan, M., Muthupandi, V. et al. Effect of Activated Flux on the Microstructure, Mechanical Properties, and Residual Stresses of Modified 9Cr-1Mo Steel Weld Joints. Metall Mater Trans B 43, 123–132 (2012). https://doi.org/10.1007/s11663-011-9568-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-011-9568-4