Abstract

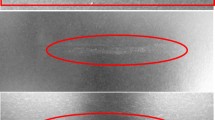

Inclusion distribution was studied in commercial aluminum DC-cast billets and slabs using a newly developed deep-etching method. Analyses revealed a nonuniform distribution of nonmetallic inclusions across billet diameters and lengths, and also across slab thicknesses and widths. In as-cast billets, more inclusions were found at the beginning and end of the billet length; more were present near the cross-section center than near the surface. In slabs, inclusions were located mostly within 13 mm of the surface and in a band between the centerline and the surface. Few inclusions were found 60 to 100 mm from the slab surface or at the centerline. In addition, comparing slab quality after casting using three types of ceramic foam filters (CFFs; i.e., 30 ppi, 50 ppi, and 50 ppi + HF) revealed significant differences in inclusion size, number, and distribution. Casting slabs using a finer pore-size filter (50 ppi) reduced the number of non-metallic inclusions greatly. The inclusion distribution patterns observed in the solidified slabs are discussed in terms of melt flow during casting.

Similar content being viewed by others

References

S. Poynton, M. Brandt, and J. Grandfield: J. Light Met., 2009, pp. 681–88.

M. Jaradeh and T. Carlberg: J. Light Met., 2007, vol. 3, pp. 679–84.

M. Jaradeh and T. Carlberg: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 121–32.

L.S. Aubrey, M.A. Cummings, and C.L. Oliver: J. Light Met., 1996, pp. 845–55.

R. Tilak: Improved Extrudability of Aluminum Alloys with LARS Refinement, Metalworld, http://www.metalworld.co.in/cover12.pdf, 2005.

Improving Performance: Billet Casting, Pyrotek Supplement, http://www.pyrotek.info/documents/brochure/873_billet_casting_insert_web.pdf.

Improving Performance: Slab Casting, Pyrotek Supplement, http://www.pyrotek.info/documents/brochure/849%20Slab%20Casting%20Insert_Web.pdf.

M. Tsunekawa, S. Tani, H. Okazaki, and N. Hayashi: Light Metal Technical Reports, 2001, pp. 831–37.

Q. Du, D.G. Eskin, and L. Katgerman: Mater. Sci. Eng. A, 2005, vols. 413–414, pp. 144-50.

S.P. Tremblay and R. Green: Continuous Casting, K. Ehrke and W. Schneider, eds., Wiley-VCH, Weinheim, Germany, 2006.

Acknowledgments

The Swedish KK-foundation and the European Regional Development Fund financially supported this research. The authors are grateful to Kubikenborg Aluminum AB for providing the sample materials and for stimulating discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 8, 2010.

Rights and permissions

About this article

Cite this article

Jaradeh, M.M., Carlberg, T. Analysis of Distribution of Nonmetallic Inclusions in Aluminum DC-Cast Billets and Slabs. Metall Mater Trans B 43, 82–91 (2012). https://doi.org/10.1007/s11663-011-9562-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-011-9562-x