Abstract

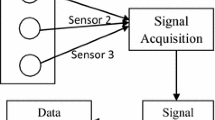

Gas stirring is commonly used in pyrometallurgical vessels to enhance mass and heat transfer and promote impurity removal. These processes can be difficult to monitor because of the severe operating conditions associated with these processes. However, experienced operators can make judgment of the process by observing the disturbance of the top surface and listening to the sound of the bubbling. In this article, we proposed a new approach of analyzing the stirring process by all the signals that could be reliably measured simultaneously, i.e., the image of the disturbed top surface, the sound of the bubbling process, and the vibrations on the wall of the vessel. The principal component analysis (PCA) results on the cold model data showed that the three types of signals are highly correlated, and they can be reduced to just one signal, which picks up most of the variation of the process and could be used to monitor the bubbling phenomena. The PCA results also showed that the combination of sound and vibration signals can still pick up most of the variations without combining the image signal from the disturbed top surface. This signal could be used as online monitoring of the stirring process and provide feedback signals for process control.

Similar content being viewed by others

Abbreviations

- A*:

-

Nondimensional spout eye area

- A e :

-

Spout eye area (m2)

- A 0 :

-

Cross sectional surface area of vessel (m2)

- h :

-

Height of upper layer (slag/oil) (m)

- Q :

-

Gas flow rate at nozzle exit (m3/s)

- \( \mathop \varepsilon \limits^{ \bullet } \) :

-

Stirring power (W/ton)

- \( \mathop V\limits^{ \bullet } \) :

-

Gas flow rate (Nm3/min)

- T :

-

Bath temperature (K)

- M :

-

Bath weight (ton)

- H :

-

Depth of gas injection (m)

- P 0 :

-

Gas pressure at the bath surface (atm)

- a :

-

Average relative spout eye area within 4.0 seconds

- v :

-

Average vibration magnitude (m/s2)

- \( \mathop {v_{i} }\limits^{ \bullet } \) :

-

Acceleration collected on the wall of the vessel at a sampling rate of 250 Hz (m/s2)

- vf :

-

Summation of vibration amplitudes corresponding to the frequency (1–120 Hz)

- l i :

-

Amplitude of the spectrum

- s :

-

Average of sound intensity (W/m2)

- sf :

-

Summation of sound amplitudes corresponding to the frequency(100–1500 Hz)

- R 2 :

-

Multiple correlation coefficient

References

E. Turkdogan and R.J. Fruehan: in Fundamentals of Iron and Steelmaking, 11th ed, R.J. Furehan, ed., The AISE Steel Foundation, Warrendale, PA, 1998, p. 759.

G.A. Brooks and Subagyo: 41st Ann. Conf. Metallurgists CIM, Montreal, Quebec, Canada, 2002, pp. 41–53.

F.L. Kemeny, D.I. Walker, and J.A.T. Jones, Elec. Furnace Conf., Orlando, FL, 2000, pp. 723–33.

A. McLean: Metall. Mater. Trans. B, 2006, vol. 37B, no. 3, pp. 319–32.

M.H. Bharati and J.F. MacGregor: Ind. Eng. Chem. Res., 1998, vol. 37, pp. 4715–25.

Subagyo and G.A. Brooks: ISIJ Int., 2003, vol. 43 (8), pp. 1286–89.

J. Shlens, A Tutorial on Principal Component Analysis, http://www.brainmapping.org/NITP/PNA/Readings/pca.pdf, 2005.

K. Krishnapisharody and G. Irons: Metall. Mater. Trans. B, 2006, vol. 37B, no. 5, pp. 763–72.

X. Xu, G.A. Brooks, W. Yang, and C. Stefanie: Ironmaking Steelmaking, in press.

K. Yonezawa and K. Schwerdtfeger: Metall. Mater. Trans. B, 1999, vol. 30B, no. 4, pp. 655–60.

K. Yonezawa and K. Schwerdtfeger: Metall. Mater. Trans. B, 1999, vol. 30B, no. 3, pp. 411–18.

K. Yonezawa and K. Schwerdtfeger: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 461–68.

K.J. Graham, K. Krishnapisharody, G.A. Irons, and J.F. MacGregor: AISTech—Iron Steel Technol. Conf. Proc., 2007, pp. 1369–79.

K.J. Graham, K. Krishnapisharody, G.A. Irons, and J.F. MacGregor: Can. Metall. Quart., 2007, vol. 46, no. 4, pp. 397–406.

Pulse-code modulation, http://en.wikipedia.org/wiki/Pulse-code_modulation, 2009.

I. Smith and A. Lindsay: A Tutorial on Principal Components Analysis, http://users.ecs.soton.ac.uk/, 2002.

Subagyo and G.A. Brooks: Yazawa Int. Symp.: Metall. Mater. Process.: Princ. Technol.; Mater. Process. Fund. New Tech., 2003, pp. 475–83.

G.A. Brooks and Subgayo: Ironmaking Steelmaking, 2003, vol. 30 (10), pp. 17–21.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 25, 2010.

Rights and permissions

About this article

Cite this article

Xu, X., Brooks, G.A. & Yang, W. Online Analysis of Stirring Processes in Ladle Metallurgy. Metall Mater Trans B 41, 1025–1032 (2010). https://doi.org/10.1007/s11663-010-9394-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-010-9394-0