Abstract

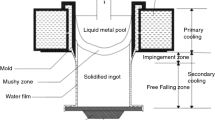

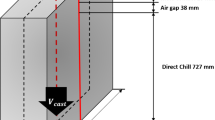

Secondary cooling information is critical when modeling the direct-chill (DC) casting process of magnesium alloys. However, accurate data for the heat flux in the secondary cooling zone are scarce, and most reported research is concerned with the DC casting of aluminum alloys. Cooling experiments that simulated the secondary cooling of magnesium AZ31 were conducted in order to observe the influence of various parameters on the different boiling-water heat-transfer phenomena. The heat flux in each boiling regime was quantified as a function of the cooling-water flow rate, water temperature, and initial sample temperature. Equations developed from the cooling experiments could be combined to build “idealized” boiling curves for a given set of DC casting conditions.

Similar content being viewed by others

Abbreviations

- C f :

-

coefficient in Rohsenow’s NPB model (—)

- C p :

-

specific heat (J kg−1 K−1)

- D :

-

billet diameter (m)

- d IZ :

-

distance from water-jet IZ (mm)

- Fo:

-

Fourier number (—)

- g :

-

gravitational acceleration (m s−2)

- h :

-

heat-transfer coefficient (W m−2 K−1)

- i fg :

-

latent heat of evaporation (J kg−1)

- k :

-

thermal conductivity (W m−1 K−1)

- Q :

-

volumetric cooling-water flow rate (m3 s−1)

- Q′:

-

volumetric cooling-water flow rate per unit of perimeter (L min−1 m−1)

- r :

-

exponent in Rohsenow’s NPB model (—)

- T 0 :

-

initial temperature (°C)

- T f :

-

water bulk temperature (°C)

- T LPt :

-

Leidenfrost point temperature (°C)

- T ONB :

-

onset of NB temperature (°C)

- T s :

-

surface temperature (°C)

- T sat :

-

water saturation temperature (°C)

- T wet :

-

rewetting temperature (°C)

- t :

-

time (s)

- v c :

-

sample moving speed (mm s−1)

- v f :

-

water-jet velocity (m s−1)

- x :

-

sample thickness dimension (m)

- z :

-

sample height dimension (m)

- Δt :

-

time-step length (s)

- ε th :

-

thermal effusivity (J m−2 K−1 s−0.5)

- Φ:

-

heat flux (W m−2)

- μ f :

-

water viscosity (kg m−1 s−1)

- θ f :

-

water-jet-impingement angle (deg)

- ρ :

-

density (kg m−3)

- σ fg :

-

surface tension at the water/steam interface (N m−1)

References

P. Baker: Light Met. (Métaux Légers), 1997, pp. 355–67.

H. Hao, D.M. Maijer, M.A. Wells, S.L. Cockcroft, D. Sediako, and S. Hibbins: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3842–54.

J.F. Grandfield, A. Hoadley, and S. Instone: Light Met., 1997, pp. 691–99.

J. Sengupta, S.L. Cockcroft, D.M. Maijer, M.A. Wells, and A. Larouche: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 532–39.

J. Sengupta, S.L. Cockcroft, D.M. Maijer, M.A. Wells, and A. Larouche: J. Light Met., 2002, vol. 2, pp. 137–48.

W. Roth: Aluminium, 1943, pp. 283–91.

H. Klein: Giesserei, 1953, vol. 10, pp. 441–54.

R. Siegel: Int. J. Heat Mass Transfer, 1978, vol. 21, pp. 1421–30.

D.J.P. Adenis, K.H. Coats, and D.V. Ragone: J. Inst. Met., 1962–1963, vol. 91, pp. 395–403.

D.A. Peel and A.E. Pengelly: Mathematical Models in Metallurgical Process Development, Iron and Steel Institute, 1969, pp. 186–96.

D.C. Weckman, R.J. Pick, and P. Niessen: Z. Metallkd., 1979, vol. 70 (11), pp. 750–57.

D.C. Weckman and P. Niessen: Metall. Trans. B, 1982, vol. 13B, pp. 593–602.

J. Du, B.S.J. Kang, K.M. Chang, and J. Harris: Light Met., 1998, pp. 1025–30.

G.P. Grealy, J.L. Davis, E.K. Jensen, P.A. Tøndel, and J. Moritz: Light Met., 2001, pp. 813–21.

J.G. Collier and J.R. Thome: Convective Boiling and Condensation, 4th ed., Oxford University Press, Oxford, United Kingdom, 1996, pp. 148–69.

S.G. Hibbins: Light Met. (Métaux Légers), 1998, pp. 265–80.

Q.C. Le, S.J. Guo, Z.H. Zhao, J.Z. Cui, and X.J. Zhang: J. Mater. Process. Technol., 2007, vol. 183, pp. 194–201.

H. Yu: Light Met., 1985, pp. 1331–47.

J. Langlais, T. Bourgeois, Y. Caron, G. Béland, and D. Bernard: Light Met., 1995, pp. 979–86.

E.K. Jensen, S. Johansen, T. Bergstrøm, and J.A. Bakken: Light Met., 1986, pp. 891–96.

J.A. Bakken and T. Bergstrøm: Light Met., 1986, pp. 883–89.

E.D. Tarapore: Light Met., 1989, pp. 875–80.

J.B. Wiskel and S.L. Cockcroft: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 119–27.

J.B. Wiskel and S.L. Cockcroft: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 129–37.

K. Kuwana, S. Viswanathan, J.A. Clark, A. Sabau, M.I. Hassan, K. Saito, and S. Das: Light Met., 2005, pp. 989–93.

H. Kraushaar, R. Jeschar, V. Heidt, E.K. Jensen, and W. Schneider: Light Met., 1995, pp. 1055–59.

L. Maenner, B. Magnin, and Y. Caratini: Light Met., 1997, pp. 701–07.

A. Larouche, Y. Caron, and D. Kocaefe: Light Met., 1998, pp. 1059–64.

I.J. Opstelten and J.M. Rabenberg: Light Met., 1999, pp. 729–35.

L.I. Kiss, T. Meenken, A. Charette, Y. Lefebvre, and R. Lévesque: Light Met., 2002, pp. 981–85.

M.A. Wells, D. Li, and S.L. Cockcroft: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 929–39.

H. Yu: Light Met., 2005, pp. 983–87.

E. Caron, M.A. Wells, and D. Li: Metall. Mater. Trans. B, 2006, vol. 37B, pp. 475–83.

G.A. Franco, E. Caron, and M.A. Wells: Metall. Mater. Trans. B, 2007, vol. 38B, pp. 949–56.

J.V. Beck, B. Blackwell, and C.R. St. Clair, Jr.: Inverse Heat Conduction: Ill-Posed Problems, John Wiley & Sons, Hoboken, NJ, 1985, pp. 108–61.

E. Caron and M.A. Wells: Proc. 10th Int. Conf. Aluminum Alloys, Vancouver, BC, Canada, 2006.

E. Caron and M.A. Wells: Aluminium Cast House Technol. 2007—Proc. 10th Australasian Conf. Exhib., Sydney, NSW, Australia, 2007.

J. Filipovic, F.P. Incropera, and R. Viskanta: Exp. Heat Transfer, 1995, vol. 8, pp. 257–70.

R.I. Vachon, G.E. Tanger, D.L. Davis, and G.H. Nix: J. Heat Transfer, 1968, pp. 239–47.

D. Li, M.A. Wells, S.L. Cockcroft, and E. Caron: Metall. Mater. Trans. B, 2007, vol. 38B, pp. 901–10.

M. Bamberger and B. Prinz: Mater. Sci. Technol., 1986, vol. 2, pp. 410–15.

E. Caron and M.A. Wells: Aluminium Alloys: Their Physical and Mechanical Properties—Proc. 11th Int. Conf. Aluminum Alloys, Aachen, Germany, 2008.

R. Jeschar, U. Reiners, and R. Scholz: Steelmaking Proc., 1986, vol. 69, pp. 511–21.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 5, 2008.

Rights and permissions

About this article

Cite this article

Caron, E., Wells, M. Secondary Cooling in the Direct-Chill Casting of Magnesium Alloy AZ31. Metall Mater Trans B 40, 585–595 (2009). https://doi.org/10.1007/s11663-009-9254-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-009-9254-y