Abstract

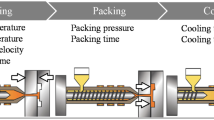

OptCast is an integrated thermal optimization tool coupling commercial casting simulation software with optimization software iSIGHT. Two types of optimizations are realized in OptCast: one uses an inverse modeling approach to determine boundary conditions such as interfacial heat-transfer coefficients (HTCs), and the other optimizes casting process variables by minimizing cycle time while maintaining casting quality. In this article, the global architecture and the development of OptCast for the commercial casting simulation software MagmaSoft is described. The determination of interfacial HTCs with OptCast for the casting process and the water quenching process is discussed. The optimized HTCs for a specific casting process are applied to a V8 engine block for thermal analysis with sufficient accuracy to enable prediction of microstructures and mechanical properties. The optimized HTCs for a water quenching process were applied to a cylinder head for residual stress analysis.

Similar content being viewed by others

References

J.E. Allison, M. Li, C. Wolverton, X.M. Su: JOM, 2006, vol. 58 (11), pp. 28–35

K. Ho and R.D. Pehlke: AFS Trans., 1983, pp. 689–98

K. Ho, R.D. Pehlke: Metall. Trans. B, 1985, vol. 16B, pp. 585–94

X.C. Zeng and R.D. Pehlke: AFS Trans., 1985, pp. 405–14

J.C. Hwang, H.T. Chuang, S.H. Jong, and W.S. Hwang: AFS Trans., 1994, pp. 877–83

W.D. Griffith: Metall. Trans. B, 1999, vol. 30B, pp. 473–82

R.G. Hills, E.C. Hensel: Num. Heat Transfer, 1986, vol. 10, pp. 369–93

C.H. Huang, M.N. Ozisik, B. Sawaf: Int. J. Heat Mass Transfer, 1992, vol. 35 (7), pp. 1779–86

F.H. Harlow, J.E. Welch: Phys. Fluids, 1965, vol. 8, pp. 2182–89

G. Zoutendijk: Methods of Feasible Directions, Elsevier, Amsterdam, Netherlands, 1960

J.E. Kelley: J. SIAM, 1960, pp. 703–12

M. Melanie: An Introduction to Genetic Algorithms, MIT Press, Cambridge, MA, 1996

X.Y. Yan, L. Ding, S.-L. Chen, F.-Y. Xie, M. Chu, Y.A. Chang: Light Metals 2001, TMS, Warrendale, PA, 2001, pp. 1091–97

M. Li, R. Vijayaraghavan, C. Wolverton, J.E. Allison: 1st Int. Symp. on Metallurgical Modeling for Aluminum Alloys, ASM INTERNATIONAL Pittsburgh, PA, 2003, pp. 79–86

S.C. Weakley-Bollin, W. Donlon, C. Wolverton, J.W. Jones, J.E. Allison: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 2407–17

R. Jeschar, E. Specht, and C. Kohler: in Theory and Technology of Quenching, B. Liscic, H.M. Tensi, and W. Luty, eds., Springer-Verlag, New York, NY, 1992

M. Newman: Ph.D. Dissertation, University of Illinois at Urbana-Champaign, Urbana, IL, 2001

J.V. Lasecki, X.M. Su, and J.E. Allison: SAE Int., 2006-01-0324

X. Su, J. Jan, and J.E. Allison: Paper presented at the ASM Material Solution and Exhibition, Pittsburgh, PA, Oct. 15–17, 2003

R. Neu, H. Sehitoglu: Metall. Mater. Trans. A, 1989, vol. 20A, pp. 1755–83

Acknowledgments

The authors thank Gurinder Singh for programming assistance; Ravi Vijayaraghavan for very fruitful discussions; and J.W. Zindel, L.A. Godlewski, and J.V. Lasecki for providing temperature data during casting and water quenching processes.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation made in the symposium entitled “Simulation of Aluminum Shape Casting Processing: From Design to Mechanical Properties,” which occurred March 12–16, 2006 during the TMS Spring Meeting in San Antonio, Texas, under the auspices of the Computational Materials Science and Engineering Committee, the Process Modeling, Analysis and Control Committee, the Solidification Committee, the Mechanical Behavior of Materials Committee, and the Light Metal Division/Aluminum Committee.

Rights and permissions

About this article

Cite this article

Li, M., Allison, J. Determination of Thermal Boundary Conditions for the Casting and Quenching Process with the Optimization Tool OptCast. Metall Mater Trans B 38, 567–574 (2007). https://doi.org/10.1007/s11663-007-9076-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-007-9076-8