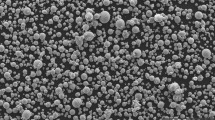

The quench sensitivity of a cast Al-7 wt pct Si-0.6 wt pct Mg alloy was characterized by tensile tests and scanning electron microscopy. Specimens were cooled from the solution treatment temperature following 58 different cooling paths including interrupted and delayed quenches. Analysis of the microstructure showed that quench precipitates were Mg2Si (β), which nucleated heterogeneously on Si eutectic particles as well as in the aluminum matrix, presumably on dislocations. The quench sensitivity of the alloy’s yield strength was modeled by multiple C-curves, using an improved methodology for quench factor analysis. The three C-curves used in the model represented loss of solute by (1) diffusion of Si to eutectic particles, (2) precipitation of β on Si eutectic particles, and (3) precipitation of β in the matrix. The model yielded a R 2 of 0.994 and a root-mean-square error (RMSE) of 7.4 MPa. The model and the implications of the results are discussed in the article.

Similar content being viewed by others

References

D.L. Zhang, L. Zheng: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 3983–91

M. Robinson: B.A.Sc. Thesis, University of Queensland, Queensland, 1996

L. Pedersen, L. Arnberg: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 525–32

Z.-W. Chen, R. Hu, W.-Q. Jie: Trans. Mater. Heat Treatment (Cailiao Rechuli Xuebao), 2004, vol. 25, pp. 76–78

P.A. Rometsch, G.B. Schaffer: Int. J. Cast Met. Res., 2000, vol. 12, pp. 431–39

T. Croucher and D. Butler: Proc. 26th Nat. SAMPE Symp., SAMPE, Covina, California, 1981, pp. 527–35

M. Tsukuda, S. Koike, M. Harada: J. Jpn. Inst. Light Met., 1978, vol. 28, pp. 8–14

J.W. Evancho, J.T. Staley: Metall. Trans., 1974, vol. 5, pp. 43–47

J.T. Staley: Mater. Sci. Technol., 1987, vol. 3, pp. 923–35

J.T. Staley, R.D. Doherty, A.P. Jaworski: Metall. Trans. A, 1993, vol. 24A, pp. 2417–27

S. Ceresara, E. Di Russo, P. Fiorini, and A. Giarda: Mater. Sci. Eng., 1969–70, vol. 5, pp. 220–27

I. Kovacs, J. Lendvai, E. Nagy: Acta Metall., 1972, vol. 20, pp. 975–83

L. Pedersen, L. Arnberg: Mater. Sci. Eng. A, 1998, vol. A241, pp. 285–89

A.L. Dons, L. Pedersen, L. Arnberg: Mater. Sci. Eng. A, 1999, vol. A271, pp. 91–94

D.L. Zhang: Mater. Sci. Forum, 1996, vol. 217–222, pp. 771–76

T. Din, J. Campbell: Mater. Sci. Technol., 1996, vol. 12, pp. 644–50

Aluminum, vol. 1: Properties, Physical Metallurgy and Phase Diagrams, K.R. Van Horn, ed., ASM, 1967

J.T. Staley: Proc. ICAA3, Trondheim, Norway, 1992, pp. 107–43

D.H. Bratland, Ø. Grong, H. Shercliff, O.R. Myhr, S.J. Tjøtta: Acta Mater., 1997, vol. 45, pp. 1–22

P.A. Rometsch, M.J. Starink, P.J. Gregson: Mater. Sci. Eng. A, 2003, vol. A339, pp. 255–64

I.T. Taylor: Can. Metall. Q., 1973, vol. 12, pp. 93–103

S.C. Bergsma, M.E. Kassner, X. Li, and R.S. Rosen: Proc. 3rd Int. Conf. on Processing and Manufacturing Advanced Materials, Las Vegas, NV, Dec. 4–8, 2000

S. Zajac, B. Bengtsson, C. Jönsson, and A. Isaksson: Proc. Extrusion Technology 2000, The Aluminum Association & Aluminum Extruders Council, Chicago, IL, 2000, pp. 73–82

M. Taya, E. Lulay, D.J. Lloyd: Acta Metall. Mater., 1991, vol. 39, pp. 73–87

I. Dutta, S.M. Allen, J.L. Hafley: Metall. Trans. A, 1991, vol. 22A, pp. 2553–63

J.M. Papazian: Metall. Trans. A, 1988, vol. 19A, pp. 2945–53

M.P. Thomas, J.E. King: Scripta Metall. Mater., 1994, vol. 31, pp. 209–14

I.N.A. Oguocha, M. Radjabi, S. Yannacopoulos: J. Mater. Sci., 2000, vol. 35, pp. 5629–34

Acknowledgment

One of the authors (MT) acknowledges a Summer Research Fellowship from Robert Morris University.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation made in the symposium entitled “Simulation of Aluminum Shape Casting Processing: From Design to Mechanical Properties,” which occurred March 12–16, 2006 during the TMS Spring Meeting in San Antonio, Texas, under the auspices of the Computational Materials Science and Engineering Committee, the Process Modeling, Analysis and Control Committee, the Solidification Committee, the Mechanical Behavior of Materials Committee, and the Light Metal Division/Aluminum Committee.

Rights and permissions

About this article

Cite this article

Tiryakioğlu, M., Shuey, R.T. Quench Sensitivity of an Al-7 Pct Si-0.6 Pct Mg Alloy: Characterization and Modeling. Metall Mater Trans B 38, 575–582 (2007). https://doi.org/10.1007/s11663-007-9027-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-007-9027-4