Abstract

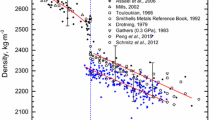

The oxide skin strength on molten aluminum has been measured as a function of temperature for pure aluminum and some aluminum alloys. The measured values fit well to previous published data of surface tension of liquid aluminum, σ lg , combined with the wetting angle, ϑ, and the mechanical strength of the oxide. It is assumed that the work per area needed to stretch and rupture the oxide skin is a sum of the interfacial tensions and tensile strength of oxide, times oxide thickness:

The work per area calculated from previous published data fits reasonably well with the oxide skin strength measurements presented here. It is found that above about 750 °C, the oxide skin strength increases with increasing temperature. The effect of sodium addition to industrially pure aluminum has also been investigated. Addition of 68 ppm sodium increases the oxide skin strength by 52 pct. Addition of 0.3 pct magnesium to A1-11Si reduces the oxide skin strength by 30 to 35 pct below 620 °C.

Similar content being viewed by others

References

T.A. Engh: Principles of Metal Refining, Oxford Science Publishers, Oxford University Press, Oxford, United Kingdom, 1992.

S. Benum: Light Met., 1999, pp. 737–42.

J. Campbell: Castings, 2nd ed., Elsevier, Oxford, United Kingdom, 2003.

W. Kahl and E. Fromm: Metall. Trans. B, 1985, vol. 16B, pp. 47–51.

W. Thiele: Aluminum, 1962, vol. 38 (12), pp. 707–15.

S. Freti, J.-D. Bornand, and K. Buxmann: Light Met., 1982, pp. 1003–16

C.N. Cochran, D.L. Belitskus, and D.L. Kinesz: Metall. Trans. B, 1977, vol. 8B, pp. 323–32.

L. Zhong: Proc. Int. Conf. on Interfaces in Metal-Ceramics Composites, TMS Annual Meeting, Anaheim, CA, Feb. 1990, TMS, Warrendale, PA, 1990, pp. 213–26.

Quincke: Ann. Phys., 1897, vol. 61, pp. 4–137, cited in Ref. 12.

W. Jung: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 51–55.

S.M. Wolf, A.P. Levitt, and J. Brown: Chem. Eng. Progr., 1966, vol. 62 (3), pp. 74–78.

CRC Handbook of Chemistry and Physics, 71st ed., CRC Press, Boston, MA, 1990–91.

B. Keene: Int. Mater. Rev., 1993, vol. 38 (4), pp. 157–92.

L. Goumiri and J.C. Joud: Acta Metall., 1982, vol. 30, pp. 1397–405.

Ceramic Fabrication Processes, W.D. Kingery, ed., The MIT Press, Cambridge, MA, 1956, pp. 213–28.

C. Wagner: Z. Phys. Chem., 1933, vol. B21.

W. Kahl: Ph.D. Thesis, University of Stuttgart, Deutchland, Germany, 1983.

G.K. Sigworth: Light Met., 2000, pp. 773–78.

G.L. Squires: Practical Physics, 3rd ed., Cambridge University Press, Cambridge, United Kingdom. 1985.

H. John and H. Hausner: J. Mater. Sci. Lett., Letter 5, 1986, pp. 549–51.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Syvertsen, M. Oxide skin strength on molten aluminum. Metall Mater Trans B 37, 495–504 (2006). https://doi.org/10.1007/s11663-006-0033-8

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-006-0033-8