Abstract

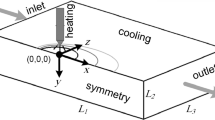

A three-dimensional mathematical model was developed to simulate the flow patterns and temperature distributions in a moving A-TIG weld pool of 304 stainless steels with different oxygen content using PHOENICS software. It is shown that the surface-active element, oxygen, is important, because it affects the weld shape by changing the flow patterns in the weld pool. The weld bead penetration and the depth/width ratio increase first sharply and then remain nearly a constant with increasing oxygen content. Depending upon the oxygen contents, three, one, or two vortexes that have different positions, strength, and directions may be found in the weld pool. Oxygen can cause significant changes in the weld shape by varying the sign of the surface tension coefficient. The situation with the maximum surface tension moves from the edge to the center with increasing oxygen content. As oxygen content exceeds a critical value, a positive surface tension coefficient dominates the flow patterns. The vortexes with opposite directions caused by positive surface tension coefficient can efficiently transfer the thermal energy from the arc, creating a deep weld pool. The critical oxygen content increases with the increase of the welding current.

Similar content being viewed by others

References

S.M. Gurevich and V.N. Zamkov: Avt Svarka, 1966, vol. 12, pp. 13–16.

R.H. Zhang, D. Fan, and Y. Yin: J. Gansu Univ. Technol., 2001, vol. 4, pp. 8–10.

R.H. Zhang and D. Fan: J. Gansu Univ. Technol., 2002, vol. 6, pp. 12–14.

W. Lucas: Welding Met. Fabric., 1996, vol. 64, pp. 11–17.

T. Paskell: Welding J., 1997, vol. 76, pp. 57–60.

C.L. Yang, M. Ushio, and M. Tanaka: Welding, 2000, vol. 5, pp. 15–18.

C.R. Heiple and J.R. Roper: Welding J., 1982, vol. 61, pp. 97–101.

C.R. Heiple and J.R. Roper: Welding J., 1983, vol. 62, pp. 72–77.

C.R. Heiple and J.R. Roper: Welding J., 1981, vol. 60, pp. 143–45.

S.P. Lu, M. Tanaka, and K. Nogi: Mater. Trans., 2002, vol. 43, pp. 2926–31.

S.P. Lu, H. Fujii, and K. Nogi: Scripta Mater., 2004, vol. 51, pp. 271–77.

H. Xe, P.W. Fuerschbach, and T. DebRoy: J. Phys. D, 2003, vol. 36, pp. 1388–98.

A. Robert and T. DebRoy: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 941–47.

K. Mundra, T. DebRoy, and T. Zacharia: Welding J., 1992, vol. 71, pp. 313s-20s.

T. Zacharia and S.A. David: Welding J., 1989, vol. 68, pp. 499s-509s.

T. Zacharia and S.A. David: Welding J., 1989, vol. 68, pp. 510s-19s.

S. Kou and D.K. Sun: Metall. Trans. A, 1985, vol. 16A, pp. 203–13.

Y. Wang, Q. Shi, and H.L. Tsai: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 145–61.

Y. Wang and H.L. Tsai: Metall. Mater. B, 2001, vol. 32B, pp. 501–15.

P. Sahoo, T. DebRoy, and M.J. McNallan: Metall. Mater. Trans. B, 1998, vol. 29B, pp. 483–87.

F.Y. Liu and S.B. Lin: Trans. China Welding Inst., 2002, vol. 2, pp. 5–8.

C.L. Yang: Chin. J. Mech. Eng., 2000, vol. 36, pp. 59–63.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhao, Y., Shi, Y. & Lei, Y. The study of surface-active element oxygen on flow patterns and penetration in A-TIG welding. Metall Mater Trans B 37, 485–493 (2006). https://doi.org/10.1007/s11663-006-0032-9

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-006-0032-9