Abstract

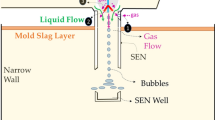

Fundamentally based computational models are developed and applied to quantify the removal of inclusions by bubbles during the continuous casting of steel. First, the attachment probability of inclusions on a bubble surface is investigated based on fundamental fluid flow simulations, incorporating the turbulent inclusion trajectory and sliding time of each individual inclusion along the bubble surface as a function of particle and bubble size. Then, the turbulent fluid flow in a typical continuous casting mold, trajectories of bubbles, and their path length in the mold are calculated. The change in inclusion distribution due to removal by bubble transport in the mold is calculated based on the computed attachment probability of inclusions on each bubble and the computed path length of the bubbles. In addition to quantifying inclusion removal for many different cases, the results are important to evaluate the significance of different inclusion-removal mechanisms. The modeling approach presented here is a powerful tool for investigating multiscale phenomena in steelmaking and casting operations to learn how to optimize conditions to lower defects.

Similar content being viewed by others

References

W. Pan, K. Uemura, and S. Koyama: Tetsu to Hagane, 1992, vol. 78 (8), pp. 87–94.

L. Wang, H.-G. Lee, and P. Hayes: Steel Res., 1995, vol. 66 (7), pp. 279–86.

L. Zhang and S. Taniguchi: Int. Mater. Rev., 2000, vol. 45 (2), pp. 59–82.

L. Zhang: Modell. Simul. Mater. Sci. Eng., 2000, vol. 8 (4), pp. 463–76.

L. Zhang and S. Taniguchi: Fluid flow and particle removal by bubble flotation in a mechanically stirred vessel. Materials Processing in the Computer Age III, 2000, pp. 111–22.

L. Zhang and S. Taniguchi: Ironmaking Steelmaking, 2002, vol. 29 (5), pp. 326–36.

G. Abbel, W. Damen, G. de Dendt, and W. Tiekink: ISIJ, 1996, vol. 36, pp. S219–22.

W.H. Emling, T.A. Waugaman, S.L. Feldbauer, and A.W. Cramb: in Steelmaking Conference Proceedings, vol. 77, Chicago, IL, April 13–16, 1997, ISS, Warrendale, PA, 1994, pp. 371–79.

L. Kiriha, H. Tosawa, and K. Sorimachi: VCAMP-ISIJ, 2000, vol. 13, p. 120.

B.G. Thomas, A. Denissov, and H. Bai: in Steelmaking Conference Proceedings, vol. 80, Chicago, IL, April 13–16, 1997, ISS, Warrendale, PA, 1997, pp. 375–84.

J. Knoepke, M. Hubbard, J. Kelly, R. Kittridge, and J. Lucas: in Steelmaking Conference Proceedings, vol. 77, ISS, Warrendale, PA, 1994, pp. 381–88.

N. Kasai, H. Mizukami, and A. Mutou: Tetsu to Hagane, 2003, vol. 89 (11), pp. 1120–27.

L. Zhang, B. Rietow, K. Eakin, and B.G. Thomas: ISIJ Inter., 2006, vol. 46, in press.

Y. Miki and S. Takeuchi: ISIJ Int., 2003, vol. 43 (10), pp. 1548–55.

R. Gass, H. Knoepke, J. Moscoe, R. Shah, J. Beck, J. Dzierzawski, and P.E. Ponikvar: in ISSTech2003 Conference Proceedings, ISS, Warrendale, PA, 2003, pp. 3–18.

P. Rocabois, J.-N. Pontoire, V. Delville, and I. Marolleau: in ISSTech2003 Conference Proceedings, ISS, Warrendale, PA, 2003, pp. 995–1006.

H. Yin and H.T. Tsai: in ISSTech2003 Conference Proceedings, ISS, Warrendale, PA, 2003, pp. 217–26.

H.J. Schulze: in Developments in Mineral Processing, vol. 4, D.W. Fuerstenau, ed., Elsevier, 1984, pp. 65–66.

L. Wang, H.-G. Lee, and P. Hayes: ISIJ Int., 1996, vol. 36 (1), pp. 17–24.

X. Zheng, P. Hayes, and H.-G. Lee: ISIJ Int., 1997, vol. 37 (11), pp. 1091–97.

N. Ahmed and G.J. Jamson: Miner. Process. Extr. Metall. Rev., 1989, vol. 5, pp. 77–99.

A.G. Szekely: Metall. Trans. B, 1976, vol. 7B (3), pp. 259–70.

K. Okumura, M. Kitazawa, N. Hakamada, M. Hirasawa, M. Sano, and K. Mori: ISIJ Inter., 1995, vol. 35 (7), pp. 832–37.

P.E. Anagbo and J.K. Brimacombe: Metall. Mater. Trans., 1990, vol. 21B, pp. 637–48.

Y. Miki, B.G. Thomas, A. Denissov, and Y. Shimada: Iron and Steelmaker, 1997, vol. 24 (8), pp. 31–38.

Y. Ye and J.D. Miller: Int. J. Miner. Process., 1989, vol. 25 (3–4), pp. 199–219.

H.J. Schulze: Miner. Process. Extractive Metall. Rev., 1989, vol. 5, pp. 43–76.

Y. Xie, S. Orsten, and F. Oeters: ISIJ Int., 1992, vol. 32 (1), pp. 66–75.

R.M. Wellek, A.K. Agrawal, and A.H.P. Skelland: AIChE J., 1966, vol. 12 (5), pp. 854–62.

Y. Sahai and R.I.L. Guthrie: Metall. Trans. B., vol. 13B (2), pp. 193–202.

H. Tokunaga, M. Iguchi, and H. Tatemichi: Metall. Mater. Trans. B, 1999, vol. 30B (1), pp. 61–66.

M. Iguchi, H. Tokunaga, and H. Tatemichi: Metall. Mater. Trans. B, 1999, vol. 28B (6), pp. 1053–61.

H. Bai: Ph.D. Thesis, University of Illinois, 2000.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B (4), pp. 702–22.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B (2), pp. 253–67.

W. Damen, G. Abbel and G. de Dendt: Revue de Metallurgie CIT, 1997, vol. 94 (6), pp. 745–50.

M. Sevik and S.H. Park: J. Fluids Eng. Trans. AIME, 1973, pp. 53–60.

S. Yokoya, S. Takagi, K. Tada, M. Iguchi, K. Marukawa, and S. Hara: ISIJ Int., 2001, vol. 41 (10), pp. 1201–07.

S. Yokoya, S. Takagi, S. Ootani, M. Iguchi, and K. Marukawa: ISIJ Int., 2001, vol. 41 (10), pp. 1208–14.

S. Yokoya, S. Takagi, M. Kaneko, M. Iguchi, K. Marukawa, and S. Hara: ISIJ Int., 2001, vol. 41 (10), pp. 1215–20.

S. Yokoya, S. Takagi, M. Iguchi, K. Marukawa, and S. Hara: ISIJ Int., 2001, vol. 41 (Suppl), pp. S47–51.

FLUENT 6.1 Manual. Fluent Inc., Lebanon, NH, 2003.

J. Aoki, L. Zhang, and B.G. Thomas: in ICS 2005: The 3rd International Congress on the Science and Technology of Steelmaking, AIST, Warrendale, PA, 2005, pp. 319–22.

FLUENT 5.1. Fluent Inc., Lebanon, NH, 2000.

R. Clift, J.R. Grace, and M.E. Weber: Bubbles, Drops and Particles. Academic Press, Inc., New York, NY, 1978.

J. Aoki: Master Thesis, University of Illinois at Urbana-Champaign, 2006.

L. Zhang and B.G. Thomas: in Proceedings of XXIV Steelmaking National Symposium, Mexico, 2003.

B.G. Thomas and L. Zhang: ISIJ Inter., 2001, vol. 41 (10), pp. 1181–93.

L. Zhang and B.G. Thomas: Particle Motion with Random Walk Model in k-e Two-Equation Model Compared with LES Simulation. University of Illinois at Urbana-Champaign, Report No. CCC200501, 2005.

Q. Yuan, B.G. Thomas, and S.P. Vanka: Metall. Mater. Trans. B., 2004, vol. 35B (4), pp. 703–14.

M. Yemmou, M.A.A. Azouni, and P. Casses: J. Cryst. Growth, 1993, vol. 128 (4), pp. 1130–36.

J.K. Kim and P.K. Rohatgi: Metall. Mater. Trans. B, 1998, vol. 29A (1), pp. 351–75.

D.M. Stefanescu and A.V. Catalina: ISIJ Inter., 1998, vol. 38 (5), pp. 503–05.

B.G. Thomas, L. Zhang, and T. Shi: Effect of Argon Gas Distribution on Fluid Flow in the Mold Using Time-Averaged k-e Models, University of Illinois at Urbana-Champaign, Report No. CCC200105, 2001.

L. Zhang and B.G. Thomas: ISIJ Inter., 2003, vol. 43 (3), pp. 271–91.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 1143–59.

L. Zhang, B.G. Thomas, K. Cai, L. Zhu and J. Cui: in ISSTech 2003, ISS, Warrendale, PA, 2003, pp. 141–56.

H. Schubert: Int. J. Miner. Process., 1999, vol. 56, pp. 257–76.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhang, L., Aoki, J. & Thomas, B.G. Inclusion removal by bubble flotation in a continuous casting mold. Metall Mater Trans B 37, 361–379 (2006). https://doi.org/10.1007/s11663-006-0021-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-006-0021-z