Abstract

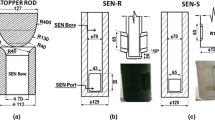

The structure of the turbulent flow in a slab mold is studied using a water model, various experimental techniques, and mathematical simulations. The meniscus stability depends on the turbulence structure of the flow in the mold; mathematical simulations using the k-ε model and the Reynolds-stress model (RSM) indicate that the latter is better at predicting the meniscus profile for a given casting speed. Reynolds stresses and flow vorticity measured through the particle-image velocimetry (PIV) technique are very close to those predicted by the RSM model, and maximum and minimum values across the jet diameter are reported. The backflow in the upper side of the submerged entry nozzle (SEN) port (for a fixed SEN design) depends on the casting speed and disappears, increasing this process parameter. At low casting speeds, the jet does not report enough dissipation of energy, so the upper flow roll is able to reach the SEN port. At high casting speeds, the jet energy is strongly dissipated inside the SEN port, the narrow wall, and in the mold corner, weakening the momentum transfer of the upper flow roll, which is unable to reach the SEN port. At low casting speeds, meniscus instability is observed very close to the SEN, while at high casting speeds, this instability is observed in the mold corner. An optimum casting speed is reported where complete meniscus stability was observed. The flow structure at the free surface indicates a composite structure of islands with large gradients of velocity at high casting speeds. These velocity gradients are responsible for the meniscus instability.

Similar content being viewed by others

Abbreviations

- D()/Dt=∂()/∂t+u i·≡():

-

the substantial derivative of a (passive scalar), a (vector), or a (tensor) amount of the flow

- G :

-

gravity constant

- k :

-

kinetic energy

- P ij :

-

production tensor

- P :

-

pressure

- u i :

-

fluctuating velocity vector in the direction i

- 〈U i〉:

-

average velocity in the direction i

- U i :

-

instantaneous velocity in the direction i

- s ij :

-

fluctuating deformation-rate tensor

- S ij :

-

averaged deformation-rate tensor

- V c :

-

casting speed

- α :

-

volumetric phase fraction

- δ :

-

viscous-layer scale

- ε :

-

dissipation rate of kinetic energy

- μ :

-

dynamic viscosity

- ν :

-

kinematic viscosity

- ϱ mix :

-

density of the mixture

- τ :

-

strain-stress tensor

References

M.M. Wolf: Continuous Casting Volume 9, ISS, Warrendale, PA, 1997, pp. 1–46.

L. Zhang, J. Aoki, and B.G. Thomas: Materials Science and Technology 2004 Conf. Proc. Vol. II, TMS-AIST, Warrendale, PA, 2004, pp. 161–78.

R. Sánchez-Pérez, R.D. Morales, M. Díaz-Cruz, O. Olivares Xometl, and J. Palafox-Ramos: Iron Steel Inst. Jpn. Int., 2003, vol. 43, pp. 637–46.

R. Sánchez-Pérez, R.D. Morales, A. Ramos-Banderas, and J. Palafox-Ramos: Steel GRIPS J. Steel Related Mater., 2004, vol. 2, pp. 57–65.

R.D. Morales and R. Sanchez-Perez: AIST 2004 Iron and Steel Conf. Proc., TMMS-AIST, Warrendale, PA, 2004, pp. 659–68.

R. Sanchez-Perez, A. Ramos-Banderas, and R.D. Morales: Materials Science and Technology 2004 Conf. Proc. Vol. II, TMS-AIST, Warrendale, PA, 2004, pp. 149–60.

B.G. Thomas, D. Lui, and H. Bo: Proc. Sensors and Modeling in Materials Processing: Techniques and Applications, TMS, Warrendale, PA, 1997, pp. 117–42.

S. Sivaramakrishnan, H. Bai, B.G. Thomas, S.P. Vanka, and P.H. Dauby: 83rd Steelmaking Conf. Proc., ISS, Warrendale PA, 2000, vol. 83, pp. 541–57.

Q. Yuan, B.G. Thomas, and S.P. Vanka: ISS Technol. 2003 Conf. Proc., AIST, Warrendale, PA, 2003, pp. 913–27.

Q. Yuan, T. Shi, S.P. Vanka, and B.G. Thomas: Proc. Computational Modeling of Materials, Minerals and Metals Processing, Cross, Bailey, and Evans, eds., Warrendale, PA, 2001, pp. 491–500.

D. Gupta and A.K. Lahiri: Metall. Mater. Trans. B, 1993, vol. 25B, pp. 227–33.

B.G. Thomas and L. Zhang: Iron Steel Inst. Jpn. Int., 2001, vol. 41, pp. 1181–93.

A. Theodorakakos and G. Bergeles: Metall. Mater. Trans. B, 1998, vol. 29B, pp. 1321–27.

J. Anagnostopoulos and G. Bergeles: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 1095–1105.

K. Takatani, Y. Tanizawa, H. Mizukami, and K. Nishimura: Iron Steel Inst. Jpn. Int., 2001, vol. 41, pp. 1261–62.

R. Sanchez-Perez, R.D. Morales, L. Garcia-Demedices, J. Palafox-Ramos, and M. Diaz-Cruz: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 85–99.

C.W. Hirt and B.D. Nicholls: J. Comp. Phys., 1981, vol. 39, pp. 201–21.

D.C. Wilcox: Turbulence Modeling for CFD, DCW Industries Inc., La Canada, CA, 2000, pp. 103–218.

W.P. Jones and B.E. Launder: Int. J. Heat Mass Transfer, 1972, vol. 15, pp. 301–14.

J.C. Rotta: Z. Phys., 1951, vol. 29, pp. 547–72.

J. Boussinesq: Acad. Sci., 1877, vol. 23, pp. 46–50.

B.J. Daly and F.H. Harlow: Phys. Fluids, 1970, vol. 13, pp. 2634–49.

J.L. Lumley: Adv. Appl. Mech., 1978, vol. 18, pp. 123–76.

D.C. Haworth and S.B. Pope: Phys. Fluids, 1986, vol. 29, pp. 387–405.

C.G. Speziali, S. Sarkar, and T.B. Gaski: J. Fluid Mech., 1991, vol. 227, pp. 245–72.

B.E. Launder, G.J. Reece, and W. Rodi: J. Fluids Mech., 1975, vol. 68, pp. 537–66.

B.E. Launder and D.B. Spalding: Mathematical Models of Turbulence, Academic Press, London, 1972, pp. 65–180.

F.M. Najjar, B.G. Thomas, and D.E. Hershey: Metall. Mater. Trans. B, 1995, vol. 26B, pp. 749–65.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 253–67.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 269–84.

M. Iguchi, J. Yoshida, T. Shimizu, and Y. Mizuno: Iron Steel Inst. Jpn. Int., 2000, vol. 40, pp. 685–91.

Mikio Suzuki, Makoto Suzuki, and M. Nakada: Iron Steel Inst. Jpn. Int., 2001, vol. 41, pp. 670–82.

R.M. McDavid and B.G. Thomas: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 672–85.

S. Sivaramakrishnan, H. Bai, B.G. Thomas, S.P. Vanka, P.H. Dauby, and M. Assar: 83rd Steelmaking Proc., ISS, Warrendale, PA, 2000, vol. 83, pp. 541–47.

B.G. Thomas, Q. Yuan, S. Sivaramakrishnan, T. Shi, S.P. Vanka, and M.B. Assar: Iron Steel Inst. Jpn. Int., 2001, vol. 41, pp. 1262–71.

S.B. Pope: Turbulent Flows, Cambridge University Press, Cambridge, United Kingdom, 2000, pp. 264–332.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ramírez-López, P., Demedices, L.G., Dávila, O. et al. Structure of turbulent flow in a slab mold. Metall Mater Trans B 36, 787–800 (2005). https://doi.org/10.1007/s11663-005-0082-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-005-0082-4