Abstract

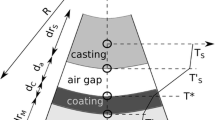

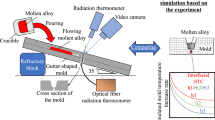

This article develops a theoretical model of the two-chamber pressure casting process. In this process, a molten metal drop, formed by arc melting a solid ingot, falls into a conical crucible attached to a gas-filled, porous cast mold. An energy-based formulation of the mold-filling process is developed which focuses on the drop’s motion within the crucible and mold cavity and on pressure evolution within the mold cavity. The model shows that drop acceleration into the mold depends on three dimensionless parameters, the Euler number, Eu, the Froude number, Fr, and the pressure loss coefficient, K, across the crucible exit. These parameters are in turn determined by the mold’s permeability to the process gas, the characteristic initial pressure difference between the interior and exterior of the mold, the mold thickness, the process gas viscosity, and the metal density. Drop acceleration into the mold compresses trapped gas within the mold cavity; under most conditions, pressure decay due to leakage of the trapped gas through the mold occurs at a faster rate than inertial compression. Under these circumstances, a downward acting pressure force, having a magnitude determined by the Euler number, acts on the drop. At low Froude numbers, however, gas compression occurs at a faster rate than leakage-induced decay and the pressure force acts upward, again with a magnitude determined by Eu. Scaling arguments show that friction and evaporation recoil forces are negligible in determining drop motion, while surface tension, pressure, drop inertia, and gravity are dominant. In addition, solidification effects are shown to be negligible.

Similar content being viewed by others

Abbreviations

- A c :

-

cross-sectional area of mold cavity

- A o :

-

cross-sectional area of crucible exit

- A s :

-

drop’s upper free surface area

- A sp :

-

characteristic area of contact between drop and crucible

- A u :

-

cross-sectional area of crucible

- h fg :

-

latent heat of vaporization

- h sl :

-

latent heat of fusion

- H cl, Lc :

-

height and width (= depth) of mold cavity

- k g :

-

gas permeability

- K :

-

pressure loss coefficient at crucible exit

- k l,, ks :

-

liquid and solid phase thermal conductivities

- L s :

-

crucible height

- m :

-

slope of crucible lateral wall

- rh g :

-

gas mass flow rate through bottom of mold

- n, n :

-

unit normal vector and normal direction

- P :

-

time-dependent mold pressure

- P c :

-

characteristic pressure on the drop’s lower surface

- P o :

-

ambient upper chamber pressure (= Pu)

- P u, Pl :

-

upper and lower chamber pressures

- q p :

-

characteristic drop surface heat flux; characteristic plasma torch flux

- Q :

-

volumetric flow rate

- R :

-

gas constant for metal evaporate

- R o :

-

crucible exit radius

- R s :

-

characteristic free surface radius of curvature

- R u :

-

crucible top radius

- T :

-

temperature

- t d :

-

thickness of mold’s bottom wall

- t f :

-

mold fill time

- T g, To :

-

process gas temperature

- T m :

-

metal melting temperature

- T b :

-

liquid metal boiling temperature

- u :

-

liquid metal velocity

- U o :

-

liquid metal speed at crucible exit; characteristic axial velocity of crucible

- U s, Uc :

-

velocity of metal drop’s upper and lower free surfaces

- U u :

-

characteristic velocity of drop’s upper free surface

- v g :

-

gas velocity within lower mold wall

- V :

-

time-dependent gas volume within mold cavity

- V d :

-

metal drop volume

- z s, zc :

-

axial positions of the drop’s upper and lower free surfaces

- α m :

-

metal thermal diffusivity

- δ :

-

characteristic viscous boundary layer thickness

- δ s :

-

characteristic solidification thickness

- ΔP :

-

pressure difference between upper and lower surfaces

- μ g :

-

process gas viscosity

- μ m :

-

liquid metal viscosity

- v m :

-

liquid metal kinematic viscosity

- ρ m :

-

liquid metal density

- Φ:

-

crucible half angle

- σ :

-

liquid metal surface tension

- τ :

-

characteristic shear strain at crucible wall

- τ fill :

-

characteristic observed mold fill time

- τ o :

-

theoretical characteristic mold fill time

References

S. Canay, N. Hersek, A. Culha, and S. Bilgic: J. Oral Rehabil., 1998, vol. 25, pp. 759–64.

T. Okabe, C. Ohkubo, I. Watanabe, O. Okuno, and Y. Takada: J. Met., 1998, vol. 50, pp. 24–29.

H. Her, M. Syverud, and M. Waarli: Dent. Mater., 1993, vol. 9, pp. 15–18.

H.S. Al-Mesmar, S.M. Morgano, and L.E. Mark: J. Prosthet. Dent., 1999, vol. 82, pp. 15–21.

T. Togaya and K. Ida: Trans. 3rd World Biomater. Congr., 1988, pp. 5p-34, 575.

M. Syverud and H. Her: Dent. Mater., 1995, vol. 11, pp. 14–18.

Y. Inoue: J. Jpn. Dent. Mater., 1995, vol. 14, pp. 302–12.

I. Watanabe, J.H. Watkins, H. Nakajima, M. Atsuta, and T. Okabe: J. Dent. Res., 1997, vol. 76, pp. 773–79.

K. Watanabe, S. Okawa, O. Miyakawa, S. Nakano, H. Honnma, N. Shiokawa, and M. Kobayashi: J. Jpn. Dent. Mater., 1993, vol. 12, pp. 496–505.

K. Watanabe, S. Okawa, M. Kanatani, T. Okabe, and O. Miyakawa: J. Jpn. Dent. Mater., 1999, vol. 18 (Spec. Iss.), p. 34.

S. Mahajan: Ph.D. Dissertation, California Institute of Technology, Pasadena, CA, 1998, pp. 22–89.

T. Togaya, S. Tsutsumi, Y. Tani, Y. Yabugami, H. Hiroshima, S. Iwaki, S. Ohyagi, and S. Shimakawa: Proc. 7th Dental Titanium Conf., 1994, pp. 11–12.

R.G. Keanini: Phys. Rev. E, 1995, vol. 52, pp. 4572–75.

P.G. Drazin and W.H. Reid: Hydrodynamic Stability, Cambridge University Press, New York, NY, 1981, pp. 19–20.

S. Ostrach: Annual Rev. Fluid Mech., Annual Reviews, Palo Alto, CA, 1982, pp. 313–45.

X. Zhang and O.A. Basaran: J. Coll. Interface Sci., 1997, vol. 187, pp. 177–78.

B. Munson, D. Young, and T. Okiishi: Fundamentals of Fluid Mechanics, 3rd ed., Wiley, New York, NY, 1998, pp. 500–01.

K. Watanabe, S. Okawa, O. Miykawa, S. Nakano, N. Shiokawa, and M. Kobayashi: J. Jpn. Dental Mater. Dev., 1991, vol. 10, pp. 77–96.

ASM Handbook, vol. 2, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, ASM INTERNATIONAL, Materials Park, OH, 1990, p. 351.

K. Watanabe: Niigata University, Niigata, Japan, private communication, 2001.

F.P. Incropera and D.P. DeWitt: Fundamentals of Heat and Mass Transfer, 4th ed., Wiley, New York, NY, 1996, p. 830.

Physics of Welding, J.F. Lancaster, ed., Pergamon Press, New York, NY, 1984, p. 112.

R.G. Keanini and B. Rubinsky: Int. J. Heat Mass Transfer, 1993, vol. 36, pp. 3283–98.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Keanini, R.G., Watanabe, K. & Okabe, T. Theoretical model of the two-chamber pressure casting process. Metall Mater Trans B 36, 283–292 (2005). https://doi.org/10.1007/s11663-005-0030-3

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-005-0030-3