Abstract

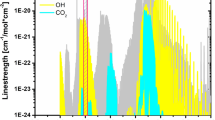

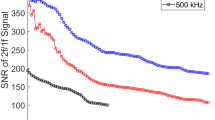

Laser-based in-situ measurements of furnace gases show promise for improving energy efficiency and pollutant emissions for steelmaking furnaces such as electric arc furnaces (EAFs). A near-infrared (IR) tunable diode laser (1.56 µm) has performed in-situ off-gas analysis of gas temperature and carbon monoxide and water concentrations in the exhaust gas region above a laboratory burner, with response times less than 1 second. These laboratory experiments related spectroscopic data to gas temperature and concentration data. The applicable range of conditions tested is representative of those found in a commercial EAF and includes temperatures from 1250 to 1650 K, CO concentration from 0 to 10 pct, and H2O concentration from 7 to 30 pct. Two-tone frequency modulation was used to increase the detection sensitivity. The method has been optimized and the measurement error has also been determined. Based on the results of the error analysis of the regression equations, the minimum accuracy of the technique has been estimated as 30 K for temperature, 0.8 pct for CO, and 3 pct for H2O using 277 test data points. This accuracy is sufficient for EAF control. Initial full-scale trials are also reported.

Similar content being viewed by others

References

M.J. Thomson, N.G. Kournetas, E. Evenson, I.D. Sommerville, A. McLean, and J. Guerrard: Ironmaking and Steelmaking, 2001, vol. 28, pp. 266–72.

E.J. Evenson, H.D. Goodfellow and J. Guerrad: Electric Furnace Conf. Proc., Iron and Steel Society, Orlando, FL, 1997, vol. 55, pp. 435–53.

J.J. Nikkari, J.M.D. Iorio, and M.J. Thomson: Appl. Optics, 2002, vol. 41, pp. 446–52.

B.L. Upschulte, D.M. Sonnenfroh, M.G. Allen, and M.F. Miller: 36th Aerospace Science Meeting & Exhibit, American Institute of Aeronautics and Astronautics, 98-0402, Reno, NV, 1998, pp. 1–12.

S.W. Allendorf, D.K. Ottesen, D.R. Hardesty, D. Goldstein, C.W. Smith, and A.P. Malcomson: Iron Steel Eng., 1998, vol. 74, pp. 31–35.

M.G. Allen: Meas. Sci. Technol., 1998, vol. 9, pp. 545–62.

J.A. Silver: Appl. Opt., 1992, vol. 31, pp. 707–12.

H.I. Schiff, G.I. Mackay, and J. Bechaa: Air Monitoring by Spectroscopic Techniques, M.W. Sigrist, ed., Wiley, New York, NY, 1994, pp. 239–333.

W.J. Kessier, M.G. Allen, and S.J. Davis: J. Quant. Spectrosc. Radiat. Transfer, 1993, vol. 49, pp. 107–17.

B.L. Upschulte, D.M. Sonnenfroh, and M.G. Allen: Appl. Optics, 1999, vol. 38, pp. 1506–12.

L.S. Rothman, C.P. Rinsland, A. Goldman, S.T. Massie, D.P. Edward, J.M. Flaud, A. Perrin, C. Cam-Peyrol, V. Da, J.Y. Mandin, J. Schroeder, A. McCann, R.R. Gamache, R.B. Waltson, K. Yoshino, K.V. Chance, K.W. Jucks, L.R. Brown, V. Nemtchinov, and P. Varansi: J. Quant. Spectrosc. Radiat. Transfer, 1998, vol. 60, pp. 665–710.

M.G. Allen and W.J. Kessler: AIAA, 1996, vol. 34, pp. 483–88.

Dietrich, A. Linde Gas: Steel Times Int., 2002, vol. 26, pp. 24–26.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wu, Q., Thomson, M.J. & Chanda, A. Tunable diode laser measurements of CO, H2O, and temperature near 1.56 µm for steelmaking furnace pollution control and energy efficiency. Metall Mater Trans B 36, 53–57 (2005). https://doi.org/10.1007/s11663-005-0005-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-005-0005-4