Abstract

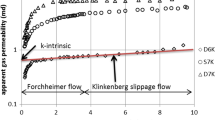

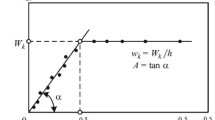

Different modifications to the classical capillary model of penetration of liquid metals into porous refractories are presented; (1) with capillaries having different radii, (2) with zigzag capillaries, and (3) with capillaries, having periodically changing capillary radius along the path of penetration. All the modified capillary models were checked against our experimental results of measuring the penetration of liquid mercury into three types of alumina refractories, having different microstructure and pore size distribution. The maximum penetration height was measured by X-ray radiography, as a function of applied outside pressure. The model with periodically changing capillary has been found to describe the experimental data satisfactorily. This model divides the process of penetration into two stages. During the first period of “pre-penetration,” the maximum penetration height changes very slowly (but not linearly) as the outside pressure is increased in the interval between the “minimum threshold pressure” and the “maximum threshold pressure.” In the second, “bulk penetration” period, appearing above the maximum threshold pressure, the maximum height of penetration increases rapidly with outside pressure, according to the classical capillary model of penetration. The three structural model parameters of the model (minimum pore radius, maximum pore radius, and period of pore structure) were connected with the measured pore size distribution curves of the refractories through semiempirical equations. As a result, our complex semiempirical model is able to predict penetration diagrams for any inert liquid metal into any refractory of a similar type.

Similar content being viewed by others

References

F. Delannay, L. Froyen, and A. Deruyttere: J. Mater. Sci., 1987, vol. 22, pp. 1–16.

R. Asthana, P.K. Rohatgi, and S.N. Tewari: Processing Adv. Composites, 1992, vol. 2, pp. 1–17.

A. Mortensen and I. Jin: Int. Mater. Rev., 1992, vol. 37, pp. 101–28.

C. Garcia-Cordovilla, E. Louis, and J. Narciso: Acta Mater., 1999, vol. 47, pp. 4461–79.

G. Kaptay: in Affordable Metal-Matrix Composites for High Performance Applications, A.B. Pandey, K.L. Kendig, and T.J. Watson, eds., TMS, Warrendale, PA, 2001, pp. 71–99.

R. Scheel and F. Oeters: Arch. Eisenhüttenwes., 1971, vol. 42, pp. 769–77.

Y. Wanibe, H. Tsuchida, T. Fujisawa, and H. Sakao: Trans. Iron Steel Inst. Jpn., 1983, vol. 23, pp. 322–30 and 331–39.

A. Tsuchinari and O. Simobayashi: Taikabutsu, 1989, vol. 41, pp. 42–43.

D.M. Stefanescu, P. Delannoy, T.S. Piwonka, and S. Kacar: AFS Trans., 1991, vol. 99, pp. 761–79.

S. Niwa, C. Iwasawa, and K. Hayamizu: Taikabutsu, 1991, vol. 43, pp. 241–45.

G. Kaptay and D.M. Stefanescu: AFS Trans., 1992, vol. 100, pp. 707–12.

Z. Yu, K. Mukai, K. Kawasaki, and I. Furusato: J. Ceram. Soc. Japan, 1993, vol. 101, pp. 521–27.

H. Nakae and Y. Matsuda: J. Jpn. Foundry Eng. Soc., 1999, vol. 71, pp. 28–33.

H. Nakae and Y. Matsuda: J. Jpn. Foundry Eng. Soc., 2000, vol. 72, pp. 102–06.

K. Mukai, Z. Tao, K. Goto, Z. Li, and T. Takashima: J. Techn. Assoc. Refractories, Jpn., 2001, vol. 21, pp. 3–10.

Z. Li, K. Mukai, Z. Tao, T. Ohuchi, I. Sasaka, and S. Iitsuka: J. Techn. Assoc. Refractories. Jpn., 2001, vol. 21, pp. 65–72.

K. Mukai, Z. Tao, K. Goto, Z. Li, and T. Takashima: Scand. J. Metall., 2002, vol. 31, pp. 68–78.

T. Matsushita and T. Ohuchi: Taikabutsu, 2002, vol. 54, pp. 221–25.

T. Matsushita, T. Ohuchi, K. Mukai, I. Sasaka, and J. Yoshitomi: Taikabutsu, 2002, vol. 54, pp. 242–48.

T. Matsushita, T. Ohuchi, K. Mukai, I. Sasaka, and J. Yoshitomi: J. Techn. Assoc. Refractories, Jpn., 2003, vol. 23, pp. 15–19.

T. Matsushita, K. Mukai, T. Ohuchi, I. Sasaka, and J. Yoshitomi: Taikabutsu, 2003, vol. 55, pp. 120–27.

S.Y. Oh, J.A. Cornie, and K.C. Russel: Ceram. Eng. Sci. Proc., 1987, vol. 8, pp. 912–36

A. Alonso, A. Pamies, J. Narciso, C. Garcia-Cordovilla, and E. Louis: Metall. Trans. A, 1993, vol. 24A, pp. 1423–32

S.Y. Chong, H.V. Atkinson, and H. Jones: Mater. Sci. Eng., 1993, vol. A173, pp. 233–37.

Handbook of Physico-Chemical Properties at High Temperatures, Y. Kawai and Y. Shiraishi, eds., ISIJ, Japan, 1988.

T. Iida and R.I.L. Guthrie: The Physical Properties of Liquid Metals, Clarendon Press, Oxford, United Kingdom, 1993, p. 288.

N. Eustathopoulos, M.G. Nicholas, and B. Drevet: Wettability at High Temperatures, Pergamon, Amsterdam, The Netherlands, 1999, p. 420.

G.J.S. Maxwell: Encyclopedia Britannica, 9th ed., T.S. Baynes, ed., Samuel L. Hall, New York, NY, 1878, pp. 56–71.

E.W. Washburn: Phys. Rev., 1921, vol. 17, pp. 273–83.

K.A. Semlak and F.N. Rhines: Trans. TMS-AIME, 1958, pp. 325–31.

X.F. Yang and X.M. Xi: J. Mater. Sci., 1995, vol. 30, pp. 5099–102.

K.P. Trumble: Acta Mater., 1998, vol. 46 (7), pp. 2363–67.

G. Kaptay: Mater. Sci. Forum, 2003, vols. 414–415, pp. 419–24.

P.C. Carman: Soil Sci., 1941, vol. 52, pp. 1–14.

A. Mortensen and J.A. Cornie: Metall. Trans. A, 1987, vol. 18A, pp. 1160–63.

A. Mortensen: Metall. Trans. A, 1990, vol. 21A, p. 2287.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kaptay, G., Matsushita, T., Mukai, K. et al. On different modifications of the capillary model of penetration of inert liquid metals into porous refractories and their connection to the pore size distribution of the refractories. Metall Mater Trans B 35, 471–486 (2004). https://doi.org/10.1007/s11663-004-0048-y

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-004-0048-y