Abstract

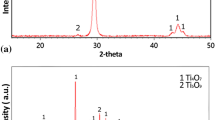

In the present work, the reaction between a molten iron drop and dense alumina was studied using the X-ray sessile-drop method under different oxygen partial pressures in the gas atmosphere. The changes in contact angles between the iron drop and the alumina substrate were followed as functions of temperature and varying partial pressures of oxygen in the temperature range 1823 to 1873 K both in static and dynamic modes. The results of the contact angle measurements with pure iron in contact with dense alumina in extremely well-purified argon as well as under different oxygen partial pressures in the gas atmosphere showed good agreement with earlier measurements reported in the literature. In the dynamic mode, when argon was replaced by a CO-CO2-Ar mixture with a well-defined \(P_{O_2 } \) in the gas, the contact angle showed an initial decrease followed by a period of nearly constant contact angle. At the end of this period, the length of which was a function of the \(P_{O_2 } \) imposed, a further steep decrease in the contact angle was noticed. An intermediate layer of FeAl2O4 was detected in the scanning electron microscope (SEM) analysis of the reacted substrates. An interesting observation in the present experiments is that the iron drop moved away from the site of the reaction once the product layer covered the interface. The results are analyzed on the basis of the various forces acting on the drop.

Similar content being viewed by others

References

C.F. Landefeld: AFM Trans., 1980, pp. 507–14.

I. Jimbo and A.W. Cramb: Iron Steel Inst. J. Int., 1992, vol. 32, pp. 26–35.

A. Kasama, A. McLean, W.A. Miller, Z. Morita, and M.J. Ward: Can. Metall. Q., 1983, vol. 22, pp. 9–17.

B.C. Allen and W.D. Kingery: J. Met., 1959, vol. 215, pp. 30–37.

M. Humenik and W.D. Kingery: J. Am. Ceram. Soc., 1954, vol. 37, pp. 18–23.

R.E. Aune and S. Seetharaman: High Temp. Mater. Processing, 1998, vol. 17, pp. 299–311.

Thermocalc, http://met.kth.se, Royal Institute of Technology Stockholm.

A. Jakobsson, N.N. Viswanathan, Du Sichen, and S. Seetharaman: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 973–80.

R.E. Brooks, I. Egry, S. Seetharaman, and D. Grant: High Temp.-High Pressures, 2001, vol. 33, pp. 631–37.

K. Nogi and K. Ogino: Can. Metall. Q., 1983, vol. 22, pp. 19–28.

Ching-Táng Wang, R.A. Karasev, and A.M. Samarin: Russ. Metall. Fuels., 1960, vol. 1, pp. 30–35.

F.A. Halden and W.D. Kingery: J. Phys. Chem., 1955, vol. 59, pp. 557–59.

P. Kozakevitch and G. Urbain: Mem. Sci. Rev. Met., 1961, vol. 58, pp. 517–34.

K. Ogino, K. Nogi, and Y. Koshida: Tetsu-to-Hagané, 1973, vol. 59, pp. 1380–87.

K. Hakashima, K. Takihira, K. Mori, and N. Shinozaki: Mater. Trans. JIM, 1992, vol. 33, pp. 918–26.

D.R. Gaskell: Introduction to Metallurgical Thermodynamics, 2nd ed., Taylor and Francis, Bristol, PA, 1981.

E. Kapilashrami, A.K. Lahiri, and S. Seetharaman: ISRN KTH/MSE-01/21-SE+METU/ART, Royal Institute of Technology, Stockholm, 2001.

Phase Diagrams for Ceramists, compiled by E.M. Levin, C.R. Robbins, and H.F. McMurdie, National Bureau of Standards, 1979, The American Ceramics Society, Westerville, OH, p. 43.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kapilashrami, E., Jakobsson, A., Seetharaman, S. et al. Studies of the wetting characteristics of liquid iron on dense alumina by the X-ray sessile drop technique. Metall Mater Trans B 34, 193–199 (2003). https://doi.org/10.1007/s11663-003-0006-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-003-0006-0