Abstract

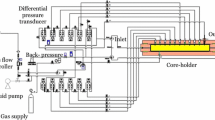

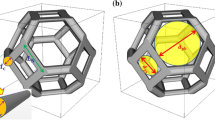

In many modern industries, complex shapes arise which require advanced metal casting processes to produce a component. The problem with these cast parts is the empiricism required to develop the casting process and the accompanying time and expense involved. There has been interest in using a fluidized bed to allow molding sand to better encapsulate the complicated surface geometries of lost-foam patterns. Fluidization, coupled with a single mixing jet of much greater magnitude than the minimum fluidization velocity, helps to homogenize the sand through stirring and may improve the integrity of the casting. At the bottom of the bed is an array of fluidizing jets distributed through a porous plate, which maintain the bed at minimum fluidization. Superimposed upon these smaller jets is a large mixing jet, which serves to mix and homogenize the sand. At issue is the hydrodynamics of the sand and air surrounding the foam pattern. The PHOENICS commercial software package was amended to simulate the flow around the precasting foam geometry. Employing a two-fluid approach, each phase was considered a fluid that interpenetrates the other phase. The modification required that the kinetic theory of granular flow for the sand phase be incorporated into the recompilable PHOENICS code. The results of this study consisted of time-averaged voidage patterns, with voidage being defined as the volume fraction of air in the mixture, around the foam pattern submerged in a two-dimensional fluidized bed. The model was benchmarked against fluidized-bed experiments performed by previous investigators. In order to elucidate the dependence of the voidage around the lost-foam pattern, selected physical parameters were varied, and the resultant void-fraction maps were predicted with the model. Physical parameters such as the aspect ratio of the width to length of the foam pattern, the placement of the mixing jet, and different mixing-jet velocities were varied to illustrate the dependence of the time-averaged void fraction on those variables. The simulations identified the presence of channeling around the lost-foam pattern, with the extent of the channeling and void formation reliant to a greater degree upon the placement of the mixing jet and, to a lesser degree, on the mixing-jet velocity and aspect ratio. The placement of the mixing jet halfway between the internal foam pattern and the right wall had the desirable benefit of granting the sand-churning benefits of a penetrating jet. With this optimal jet placement, more of the excess jet air was allowed to disperse through the molding sand and to homogenize the sand. The degree of channeling of the excess air input by the penetrating jet was minimized.

Similar content being viewed by others

References

S.I. Bakhtiyarov and R.A. Overfelt: Powder Technol., 1998, vol. 99, pp. 53–59.

J. Ding and D. Gidaspow: AIChE J., 1990, vol. 36 (4), pp. 523–38.

J.J. Nieuwland, M. van Sint Annaland, J.A.M. Kuipers, and W.P.M. van Swaaij: AIChE J., 1996, vol. 42 (6), pp. 1569–82.

A. Samuelsberg and B.H. Hjertager: Int. J. Multiphase Flow, 1996, vol. 22 (3), pp. 575–91.

N. Hudson: Master’s Thesis, Auburn University, Auburn, AL, 2001.

D. Gidaspow: Appl. Mech. Rev., 1986, vol. 39 (1), pp. 1–22.

A. Boemer, H. Qi, U. Renz, S. Vasquez, and F. Boysan: Proc. 13th Int. Conf. on Fluidized Bed Combustion, 1995, vol. 1, pp. 775–87.

J.A.M. Kuipers, W. Prins, and W.P.M. van Swaaij: Chem. Eng. Sci., 1991, vol. 46 (11), pp. 2881–94.

N. Kodikal: Master’s Thesis, Auburn University, Auburn, AL, 1999.

P.N. Rowe: Fluidization, Academic Press, New York, NY, 1971, pp. 65–119.

J.X. Bouillard, R.W. Lyczkowski, and D. Gidaspow: AIChE J., 1989, vol. 35 (6), pp. 908–22.

D. Gidaspow and B. Ettehadieh: Ind. Eng. Chem. Fundamentals, 1983, vol. 22, pp. 193–201.

D. Gidaspow, L.C. Seo, and C. Yong: Ind. Eng. Chem. Fundamentals, 1983, vol. 22, pp. 187–93.

W.C. Rivard and M.D. Torrey: LA-NUREG-6623, 1977. Los Alamos Scientific Lab, Los Alamos, New Mexico, U.S.A., New Mexico Energy Research and Development Administration.

S.V. Patankar: Numerical Heat Transfer and Fluid Flow, Hemisphere Publishing Corporation, Taylor & Francis Group, New York, NY, 1980.

S.M. Eldighidy, R.Y. Chen, and R.A. Comparin: J. Fluid Mech., 1977, vol. 365, pp. 365–70.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hudson, N., Bhavnani, S.H. & Overfelt, R.A. Computational fluid-dynamics modeling of the hydrodynamics of fluidization in the sand surrounding a lost-foam casting pattern. Metall Mater Trans B 33, 565–575 (2002). https://doi.org/10.1007/s11663-002-0036-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-002-0036-z