Abstract

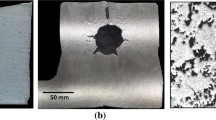

A methodology is developed to relate measured shrinkage porosity levels in steel castings to predictions from casting simulations, in order to determine feeding distances. Low-alloy steel casting trials were conducted to acquire a statistically meaningful set of experimental data for top-risered cast steel sections having various ASTM shrinkage X-ray levels. Simulations of the casting trials were then performed, using casting data recorded at the foundries during the trials. The actual casting soundness resulting from these trials, measured in terms of the ASTM shrinkage X-ray level, is quantitatively compared to the soundness predicted by simulations, measured in terms of a local thermal parameter known as the Niyama criterion. A relationship is shown to exist between the X-ray level and both the minimum Niyama criterion value as well as the area (in the plane of the X-ray) with Niyama values below a threshold value. Once the correlations developed in Part I of this article were established, an extensive set of additional casting simulations was performed to determine the feeding distances for castings with a wide variety of casting parameters. These data were then used to develop a new set of feeding-distance rules, which are given in Part II of this article.

Similar content being viewed by others

References

Yield in the Steel Casting Industry—Literature Review and Industry Survey, Steel Founders’ Society of America Special Report No. 30, Steel Founders’ Society of America, Barrington, IL, 1998.

C. Beckermann, X. Shen, J. Gu, and R.A. Hardin: 1997 SFSA Technical and Operating Conf., Steel Founders’ Society of America, Barrington, IL, 1997.

H.F. Bishop and W.S. Pellini: Am. Foundrymen’s Soc. Trans., 1950, vol. 58, pp. 185–97.

H.F. Bishop, E.T. Myskowski, and W.S. Pellini: Am. Foundrymen’s Soc. Trans., 1951, vol. 59, pp. 171–80.

E.T. Myskowski, H.F. Bishop, and W.S. Pellini: Am. Foundrymen’s Soc. Trans., 1952, vol. 60, pp. 389–400.

E.T. Myskowski, H.F. Bishop, and W.S. Pellini: Am. Foundrymen’s Soc. Trans., 1953, vol. 61, pp. 302–08.

R.E. Morey, H.F. Bishop, and W.S. Pellini: Am. Foundrymen’s Soc. Trans., 1955, vol. 63, pp. 419–24.

H.F. Bishop, E.T. Myskowski, and W.S. Pellini: Am. Foundrymen’s Soc. Trans., 1955, vol. 63, pp. 271–81.

C.W. Briggs: Determination of the Factors Influencing Riser Efficiency Part II. The Distance Risers Will Feed Uniformly Thick Sections, Steel Founders’ Society of America Research Report No. 30, Technical Research Committee Report, Steel Founders’ Society of America, Barrington, IL, Sept. 1953.

ASTM E186, 1998 Annual Book of ASTM Standards, Volume 03.03: Nondestructive Testing, ASTM, Philadelphia, PA, 1998.

ASTM E446, 1998 Annual Book of ASTM Standards, Volume 03.03: Nondestructive Testing, ASTM, Philadelphia, PA.

W.S. Pellini: Am. Foundrymen’s Soc. Trans., 1953, vol. 61, pp. 61–80.

W.D. Spiegelberg: Master’s Thesis, Case Western Reserve University, Cleveland, OH, 1968.

W.D. Spiegelberg: Ph.D. Thesis, Case Western Reserve University, Cleveland, OH, 1970.

R. Maier: Master’s Thesis, Case Western Reserve University, Cleveland, OH, 1972.

W.P. Ghun: Master’s Thesis, Case Western Reserve University, Cleveland, OH, 1974.

E. Niyama, T. Uchida, M. Morikawa, and S. Saito: Am. Foundrymen’s Soc. Int. Cast Met. J., 1982, vol. 7 (3), pp. 52–63.

Risering Steel Castings, Steel Founders’ Society of America, 1973.

G.K. Sigworth and C. Wang: Metall. Trans. B, 1993, vol. 24B, pp. 349–64.

M.C. Flemings: Solidification Processing, McGraw-Hill, New York, NY, 1974, pp. 12 and 146–54.

R.A. Hardin, S. Ou, K. Carlson, and C. Beckermann: 1999 SFSA Technical and Operating Conf., Steel Founders’ Society of America, Barrington, IL, 1999.

R.A. Hardin, S. Ou, K. Carlson, and C. Beckermann: Am. Foundrymen’s Soc. Trans., 2000, vol. 108, pp. 53–62.

ASTM E94, 1998 Annual Book of ASTM Standards, Volume 03.03: Nondestructive Testing, ASTM, Philadelphia, PA, 1998.

K. Carlson, S. Ou, R.A. Hardin, and C. Beckermann: Int. J. Cast Met. Res., 2001, vol. 14 (3), pp. 169–83.

J. Miettinen: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 281–97.

J. Miettinen and S. Louhenkilpi: Metall. Mater. Trans. B, 1994, vol. 25B, pp. 909–16.

MAGMASOFT, MAGMA GmbH, Kackerstrasse 11 52072 Aachen, Germany.

AFSolid, AFS, Inc., 505 State Street, Des Plaines, IL, 60016.

Development of a Methodology to Predict and Prevent Leaks Caused by Microporosity in Steel Castings, Steel Founders’ Society of America Research Report No. 110, Steel Founders’ Society of America, Barrington, IL, 2001.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Carlson, K.D., Hardin, R.A., Ou, S. et al. Development of new feeding-distance rules using casting simulation: Part I. Methodology. Metall Mater Trans B 33, 731–740 (2002). https://doi.org/10.1007/s11663-002-0027-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-002-0027-0