Abstract

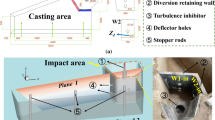

A model of a tundish has been developed that takes into account the steel, slag, and refractory phases. Predicted temperatures and velocities in the steel and refractory from the model were earlier found to agree well with measured velocities and temperatures. The model was also used to determine the optimal location of flow devices, making the temperature distribution in the steel more even and enhancing the removal of inclusions to the slag. In this study, the focus was on using the model to study the slag/steel interface in the tundish. Predictions showed that slag is dispersed into the steel close to the interface as well as close to the ladle shroud. In order to confirm these predictions, the momentary interfacial solidification sampling (MISS) method was developed. Using this method, a sample of the steel/slag interface could be taken that represented almost an instantaneous picture of the interface. The MISS sampler was used for sampling low-carbon steel in the tundish. Samples were analyzed using ultrasonic testing, optical microscopy, and scanning electron microscopy (SEM). Analysis results confirmed the presence of nonmetallic particles close to the slag/steel interface and close to the ladle shroud, as suggested by the modeling results. The analyses also showed that the slag/steel interface is very irregular, despite the low velocities.

Similar content being viewed by others

References

D. Mazumdar and R.I.L. Guthrie: Iron Steel Inst. Jpn. Int., 1999, vol. 39, p. 524.

H. Solhed, B. Wahlberg, and P. Jönsson: 5th Int. Conf. on Clean Steel Balatonszeplak, Hungary, 1997, vol. 2, pp. 1–10.

L. Prandtl: III Int. Mathematiker-Kongress, Heidelberg, 1904, Leipzig, Deutchland, 1905, pp. 484–91.

R. Higbie: Trans. Am. Inst. Chem. Eng. 1935, vol. 31, pp. 365–89.

P.V. Danckwerts: Ind. Eng. Chem., 1951, vol. 43, pp. 1460–67.

E.S. Machlin: Trans. TMS-AIME, 1960, vol. 2, pp. 314–26.

T. Kraus: Schweiz Arch. Angew. Wiss. Tech., 1962, vol. 28, pp. 452–60.

S. Asai, M. Kawachi, and I. Muchi: Scaninject III, MEFOS, Luleå Sweden, 1983, vol. 12, p. 1.

D. Mazumdar, H. Nakajiima, and R.I.L. Guthrie: Metall. Trans. B, 1988, vol. 19B, pp. 507–11.

V. Sahajwalla, J.K. Brimacombe, and M.E. Salcudean: Proc. Steelmaking Conf., Chicago, IL, 1989, ISS, vol. 72, pp. 497–501.

J. Mietz, S. Schneider, and F. Oeters: Steel Res., 1991, vol. 62, p. 1.

J. Mietz, S. Schneider, and F. Oeters: Steel Res., 1991, vol. 62, p. 10.

S.-H. Kim, R.J. Fruehan, and R.I.L. Guthrie: Iron Steelmaker, 1993, p. 71.

A.W. Cramb and I. Jimbo: Scaninject VII, MEFOS, Luleå Sweden, 1995, p. 89.

Z. Xiao, Y. Peng, and C. Liu: Chin. J. Mater. Sci. Techn., 1987, vol. 3, p. 187.

D.B. Spalding and F. Villasenor: PhysicoChem. Hydrodyn., 1987, vol. 9 (1–2), pp. 379–86.

B. Wahlberg and H. Solhed: Internal MEFOS Report No. TM00013K, MEFOS, Luleå, Sweden, March, 2000 (in Swedish).

Phoenics ver. 2 “Encyclopaedia,” CHAM Ltd., London, 1994.

Handbook of Physico-Chemical Properties at High Temperatures, Y. Kawai and Y. Shiraishi, eds., The Iron and Steel Institute of Japan, Tokyo, Japan, 1988, p. 2.

G. Ye: MEFOS Report No. MF92047, MEFOS, Luleå, Sweden, 1992.

B.C. Allen: in Liquid Metals—Chemistry and Physics, S.Z. Beer, ed., Dekker, New York, NY, 1972, p. 161.

S. Seetharaman, Du Sichen, and J.Y. Zhang: JOM, 1999, vol. 51(8) pp. 38–40.

L. Jonsson and P. Jönsson: Iron Steel Inst. Jpn., 1996, vol. 36, p. 1127.

L. Jonsson, C.-E. Grip, A. Johansson, and P. Jönsson: Proc. 80th Steelmaking Conf., Chicago, IL, Apr. 1997.

M. Hallberg, Lage Jonsson, and J. Alexis: SCANMET I, Luleå, June 7–8, 1999.

J. Alexis, P.G. Jönsson, and Lage Jonsson: Iron Steel Inst. Jpn. Int., 1999, vol. 39, p. 772.

Christer Nilsson: SSAB Tunnplåt AB, Luleå, Sweden, private communication, 1998.

H. Solhed and B. Leden: Internal MEFOS Report BTF84027B, MEFOS, Luleå, Sweden, June 1984 (in Swedish).

http://www.gmd.de/SCA1, search for Down-Port.

R.G. Olsson et al.: Trans. TMS-AIME, 1966, vol. 236, pp. 426–29.

H. Solhed and L. Jonsson: Proc. 6th Int. Conf. on Molten Slags, Fluxes and Salts, Stockholm-Helsinki, 2000.

F.D. Richardson: Metall. Trans., 1971, vol. 2, pp. 2747–56.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Solhed, H., Jonsson, L. & Jönsson, P. A theoretical and experimental study of continuous-casting tundishes focusing on slag-steel interaction. Metall Mater Trans B 33, 173–185 (2002). https://doi.org/10.1007/s11663-002-0003-8

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-002-0003-8